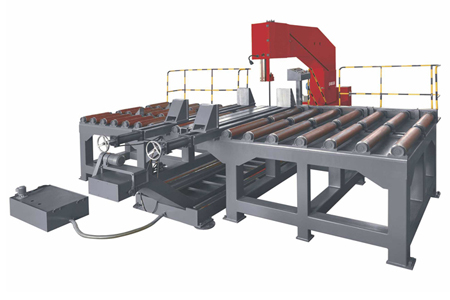

Vertical Cross Cutting Pulley Type Metal Band Saw Machine (G5480/260)

Max.cutting : Height 800mm

Capacity : Depth 2600mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Model Name | New | G5480/260 | |||||

| Max.cutting | Height | 800mm | |||||

| capacity | Depth | 2600mm | |||||

| Saw blade | Speed | 20~70 m/min (INVERTER) | |||||

| Size | 54×1.6 mm | ||||||

| Tension | Hydraulic | ||||||

| Guides | Carbide and bearing blade guides | ||||||

| Cleaning | Wire brush & flood coolant | ||||||

| Saw frame feeding | Hydraulic | ||||||

| Motor output | Blade | 11kw | |||||

| Hydraulic | 1.5kw | ||||||

| Coolant | 0.3kw | ||||||

| Feed | 2.2kw(roller table) | ||||||

| Chip conveyor | 0.3kw | ||||||

| Vise | Hydraulic(movable vise stroke 500mm) | ||||||

| Work feeding | Power roller table (infeed 3m, outfeed 3m) | ||||||

Resources & Downloads:

Vertical Cross Cutting Pulley Type Metal Band Saw Machine (G5480/260) Product Introduction :

Product description:

● This machine is mainly used for cutting large ferrous metal, medium casting, forgings, billets and slabs with a hardness of less than HRC35.

Product features:

● G54 series block vertical sawing machine adopts the “T” layout of the workpiece and saw tangent. When sawing, the saw blade is twisted 90 degrees, and the saw bow cuts the workpiece along the guide rail lengthwise;

● By hydraulic, electrical and mechanical control, stable performance;

● The main drive adopts frequency conversion speed regulation, and the saw blade line speed can be adjusted continuously and stably in the setting range;

● The feeding of the saw frame is driven by a hydraulic cylinder, and the feed guide adopts a linear guide pair. The feed is stable and reliable;

● The tension of the saw blade and the adjusting and locking of the movable guide arm of the saw blade are all controlled by hydraulic pressure, which is safe and reliable;

● The machine table is welded by rectangular steel tube and has good bearing capacity;

● Can be designed into Charles road feeding and hydraulic lifting feeding mode;

● In order to cut the cutting position accurately when sawing, the laser guide device is installed on the saw frame.

● The independent hydraulic station and control cabinet are easy to operate and maintain, and automatic chip removing devices can be selected according to the requirements;

Standard Equipment:

1. Blade cleaning brush.

2. Working light.

3. One piece of bi-metal saw blade.

4. One set of tools with tool box

5. Laser projector

6. Automatic chip conveyor

7. Hydraulic blade tension and guide arm movement

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life