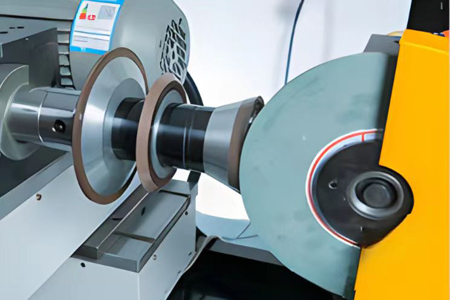

X3 Series Large Size Grinding Wheel Dresser

Maximum diameter : φ420 mm

Minimum diameter : φ20mm

Maximum width : 20 mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

Diamond Wheel Components (Dressed Wheel Components)

| Diamond seconds wheel spindle interface | Optional according to customer requirements |

| diamond grinding wheel diameter | φ420 mm |

| Small diameter diamond grinding wheel | φ20mm |

| Maximum thickness of diamond seconds wheel | 20 mm |

| Dressing wheel aperture | φ31.75mm |

| Spindle speed of diamond grinding wheel | 50-1000rpm (Step-less speed regulation) |

| Diamond grinding wheel spindle cross slide X working stroke | 135 mm |

| Diamond end wheel spindle cross slide X additional manual stroke | 150 mm |

| Diamond grinding wheel spindle cross slide Y working stroke | 135 mm |

| Diamond grinding wheel spindle cross slide Y additional manual stroke | 150 mm |

| X, Y cross slide magnetic scale resolution | 0.001mm |

| Diamond grinding wheel can trim arc radius | R0.1-30mm |

Silicon Carbide Wheel Components (Dressing Wheel Components)

| Dressing wheel (SIC) size | φ180×10×φ31.75 mm |

| Dressing wheel speed | 250-2500 rpm(Stepless speed regulation) |

| Dressing wheel swing times | 0-50/per minute (adjustable speed) |

| Dressing wheel left and right swing distance | 0-45/mm(adjustable) |

| total power | 2.0KW |

| Silicon carbide grinding wheel motor | 0.75KW |

| Dressed diamond wheel motor | 0.75KW |

| Reciprocating swing motor power | 25W |

Resources & Downloads:

X3 Series Large Size Grinding Wheel Dresser Product Introduction :

X3 is based on the principle of the difference between the speed of the dressing wheel and the dressing wheel to achieve the shape dressing of the dressing wheel. The machine itself can provide simple and efficient dressing of diamond wheels, CBN wheels and multiple wheels. It can dress planes, angles, arcs and shaped wheels. This machine is easy to operate and has high accuracy.

Features

Adopt precision linear slide-way and ball screw made in Taiwan, and add digital display grating ruler (optional), so that when the corrected grinding wheel is corrected, the positioning accuracy, width dimension and arc size can be adjusted and measured at any time.

The rotating A-axis adopts high-precision tapered roller bearings produced in Japan to achieve rotation accuracy and stability.

CCD camera device, with 15 to 120 times magnification and 17″ liquid crystal display, can measure and inspect the arc, angle and size of the grinding wheel during work.

CCD and optical size device provide easy-to-use setting and measurement of the width and position of the grinding wheel and inspection during or after dressing. The measurement accuracy can reach 0.005~0.01mm.

| Standard ACCESSORIES | PICTURE | UNIT PRICE | QUANTITY |

| Diamond spindle |  |

1600USD | 1 |

| Handwheel |  |

15USD | 3 |

| Governor |  |

25USD | 1 |

| Potentiometer |  |

5USD | 4 |

| Video capture box |  |

80USD | 1 |

| Data box |  |

120USD | 1 |

| Drive belt |  |

15USD | 2 |

| Lens hood |  |

120USD | 1 |

| Lower light source acrylic cover |  |

15USD | 1 |

| OPTIONAL ACCESSORIES | PICTURE | UNIT PRICE | QUANTITY |

| Silicon carbide grinding wheel- Outer diameter 175*Inner hole 31.75*Thickness 10 |

|

20USD | 1 |

| BT40 adapter |  |

120USD | 1 |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life