6-Axis TG680 Five-Linkage CNC Tool Grinder

Processing workpiece dia. : 200 mm

Max. processing workpiece length :

150 mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Technical Specification |Model | TG680 |

| CNC system | SYNTEC 210MA-5E |

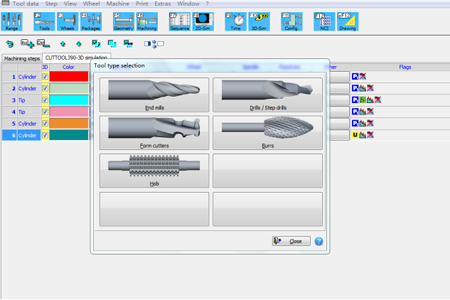

| Grinding tools software | ANTISHI |

| Processing workpiece diameter | 200 mm |

| Max. processing workpiece length | 150mm |

| Max. processing workpiece groove depth | 10mm |

| Max. Workpiece weight | 10Kg |

| Grinding head Max. Power(electric spindle) | 7 KW |

| Grinding wheels(CBN/diamond) | Φ50~Φ200mm |

| Grinding head spindle rotation speed(frequency regulation) | 1000-8000rpm |

| Grinding head vertical travel(Z axis) | 320(-100-220)mm |

| Workable travel X axis/Y-axis/Z-axis | X:285 / Y:300 / Z:320 |

| Linear axis quick travel speed | 10m/min |

| Workpiece spindle rotation speed(A-axis) | 200rpm |

| Rotation range of A-axis | ∞ |

| A axis spindle hole taper | ISO50 |

| Pneumatic clamping range | 3~20mm |

| SCHUNK collects clamping range | 3~32mm |

| Grinding head swing Max rotation speed(C-axis) | 75rpm |

| Rotation range of C-axis | 150°(+135°~-15°) |

| Workpiece spindle center height | 140mm |

| Workpiece spindle radial runout | ≤0.005mm |

| Grinding head spindle radial runout | ≤0.005mm |

| Air cylinder clamping force adjusting range | 500-580kg |

| Linear-axis resolving power | 0.001mm |

| Rotation axis resolving power | 0.001° |

| Cooling motor power | 3P |

| Cooling motor capacity | 150L |

| Voltage | AC 380V 50HZ 3 phase |

| Total power | 12 KW |

| Machine size | 1600×1550×2100mm |

| Machine weight | 3.5T |

Resources & Downloads:

6-Axis TG680 Five-Linkage CNC Tool Grinder Product Introduction :

Product Details

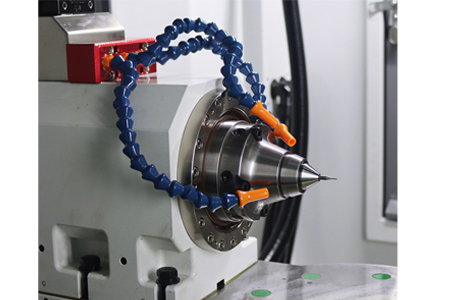

TG680 is a six-axis five-linkage CNC tool grinder newly developed by ANTISHI Company. It is a high-precision tool grinder with excellent performance. It is suitable for the production or grinding of small-size (φ1-8mm) milling tools, drilling tools, and forming tools.

Features

1.Machine tool arc shape, friendly man-machine interface, natural marble components, good stability.

2.The machine tool adopts high-precision, direct-drive frequency conversion electric spindle. The spindle has two sets of grinding wheel flanges. Each set of flanges can be equipped with 2 to 4 grinding wheels at the same time. According to the grinding process, the grinding wheel group can be changed quickly, which can fully satisfy various tools Grinding needs.

3.The workpiece spindle adopts dd direct drive, equipped with Taiwan Guangjie precision chuck body and collet, and the workpiece is automatically clamped.

4.The machine tool adopts the new generation 210MA-5E five-axis linkage control system and the Japanese Yaskawa servo unit, the Italian Marposs precision probe, the Shanghai silver precision rolling line rail and the THK ball screw, and the structure of the machine swing axis and the processing part are optimized. , To ensure the superior performance and working accuracy of the machine tool.

5.The machine tool adopts a fully enclosed appearance (movable sliding door on the front, maintenance doors on the left and back), cantilever control panel, handheld electronic handwheel, special start-stop button and foot switch, equipped with automatic cooling oil cooler and workpiece cooling Liquid control device, automatic lubrication device and mist suction interface, alarm buzzer, and electrical box cooling air-conditioning make the operation, maintenance, and maintenance changes of the machine tool simple and convenient.

Grinding Tools Sample:

Standard Equipment

Machine tool host

New generation 210MA-5E CNC system

Servo unit

ANTISHI Tool Package

RENISHAW RP3 probe

HSK quick change precision grinding wheel

Work piece pneumatic clamping device

Mist interface

automatic lubricating device

Automatic loading and unloading

Optional Equipment

Filter system

Special holding fixture

Grinding wheel

Automatic loading attachment

British RENISHAW LPDD precision probe

Marposs probe ets.

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life