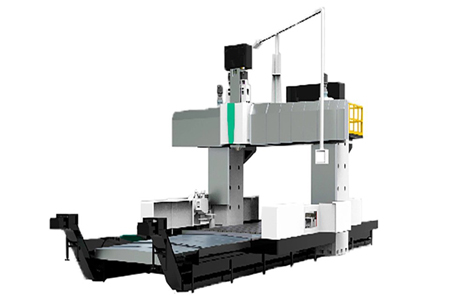

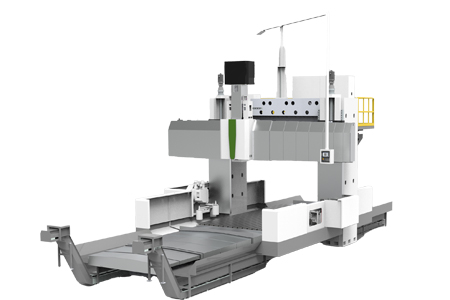

XKW21 Series Gantry CNC Milling Machine with Beam Moving

Weight capacity : 18~35T

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Model Item | Unit | XKW2132×40 | XKW2132×60 | XKW2132×80 | XKW2137×60 | XKW2137×80 |

| X axis stroke | mm | 4200 | 6200 | 8200 | 6500 | 8500 |

| Y axis stroke | mm | 3800 | 3800 | 3800 | 4300 | 4300 |

| Z axis stroke | mm | 1250 | 1250 | 1250 | 1250 | 1250 |

| W-axis travel (5×250 multi-point positioning/continuous) | mm | 1250 | 1250 | 1250 | 1250/1600 | 1250/1600 |

| Effective width of gantry | mm | 3200 | 3200 | 3200 | 3700 | 3700 |

| Maximum distance from table to spindle endface | mm | 2450 | 2450 | 2450 | 2450/2750 | 2450/2750 |

| Table size | 2500×4000 | 2500×6000 | 2500×8000 | 3000×6000 | 3000×8000 | |

| Max. loading weight | 18 | 24 | 30 | 28 | 35 | |

| T-slot (W x spacing x No.) | 28×200×12 | 28×200×12 | 28×200×12 | 28×200×14 | 28×200×14 | |

| Max. cutting speed X/Y/Z | m/min | 6/6/6 | 6/6/6 | 6/6/6 | 6/6/6 | 6/6/6 |

| Rapid movement speed X/Y/Z | m/min | 10/10/10 | 10/10/10 | 10/10/10 | 10/10/10 | 10/10/10 |

| Max. spindle speed | rpm | 4000 | 4000 | 4000 | 4000 | 4000 |

| Spindle power (continuous/30min) | kW | 22/26 | 22/26 | 22/26 | 30/37 | 30/37 |

| Spindle torque | N.m | 770/910 | 770/910 | 770/910 | 1050/1260 | 1050/1260 |

| Spindle taper | mm | BT50 | BT50 | BT50 | BT50 | BT50 |

| Ram section | mm | 450×450 | 450×450 | 450×450 | 450×450 | 450×450 |

| ATC capacity | 24/32/40/60 | 24/32/40/60 | 24/32/40/60 | 24/32/40/60 | 24/32/40/60 | |

| Max. tool diameter (full/empty) | mm | Φ125/Φ250 | Φ125/Φ250 | Φ125/Φ250 | Φ125/Φ250 | Φ125/Φ250 |

| Max. tool length | mm | 400 | 400 | 400 | 400 | 400 |

| Max. tool weight | kg | 25 | 25 | 25 | 25 | 25 |

| Accuracy (implementation standard GB/T19362.1-2003) | ||||||

| Positioning accuracy X/Y/Z | mm | 0.025/0.030/0.020 | 0.028/0.030/0.020 | 0.03/0.030/0.020 | 0.028/0.035/0.020 | 0.03/0.035/0.020 |

| Repeat positioning accuracy X/Y/Z | mm | 0.018/0.020/0.015 | 0.018/0.020/0.015 | 0.018/0.020/0.015 | 0.018/0.020/0.015 | 0.018/0.020/0.015 |

| others | ||||||

| Total power capacity | KVA | 90 | 90 | 90 | 100 | 100 |

| Machine weight | t | 72 | 80 | 90 | 100 | 112 |

| Machine dimensions (L×W×H) | cm | 1300×880×800 | 1700×880×800 | 2100×880×800 | 1700×950×820 | 2100×950×820 |

Resources & Downloads:

XKW21 Series Gantry CNC Milling Machine with Beam Moving Product Introduction :

The machine tool is a mechanical processing equipment integrating advanced technology of machine, electricity and liquid, mainly used for the processing of plane, surface and hole. Widely used in machinery manufacturing industry, a variety of plates, boxes, racks and other complex parts of the rough and finish machining, the machine tool can achieve vertical boring and milling head transverse (Y axis), vertical movement (Z axis) and table longitudinal movement (X axis) of the three-axis linkage. Multi-process machining such as milling, boring, drilling, rigid tapping, reaming and countersinking can be performed.

XKW21 Series Product Features:

1. The 450*450mm large cross-section fully contained square ram has strong rigidity and large output torque.

2. The beam and the horizontal sliding plate are equipped with rolling-sliding composite guide rails as standard, which is not only suitable for powerful cutting, but also has high precision.

3. The beam lifting adopts a multi-point lifting positioning mechanism, which has high and stable beam precision and is suitable for processing parts of different heights; the double servo synchronous control of the beam lifting is optional, with high beam positioning accuracy.

4. The Z-axis movement adopts the transmission form of double motors and double ball screws, and is controlled by the synchronous axis function of the numerical control system, which makes the movement more stable and the dynamic performance better.

5. The optimally designed bed adopts heavy-duty roller linear guide rail, which has strong rigidity and good dynamic performance.

Standard Accessories

| Siemens 828D system | Imported 20000rpm electric spindle |

| Spindle automatic constant temperature cooling circulation system | Automatic grease lubrication system or coordinate axes |

| Machine pneumatic system | Spindle taper air seal |

| Automatic chip converyor on both sides of the worktable | Cutting tool cooling system and large capacity water tank |

| Semi-closed cover | Door open switch |

| MPG | Tricolor working light |

| Electric cabinet air conditioner | Standard accessories and documents |

| Chain type chip conveyor. |

Optional Accessories

ATC

Measuring Gauge

Grating Rule

Optional Mill Head

Cooltant Through Spindle

Fourth Rotary Table

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life