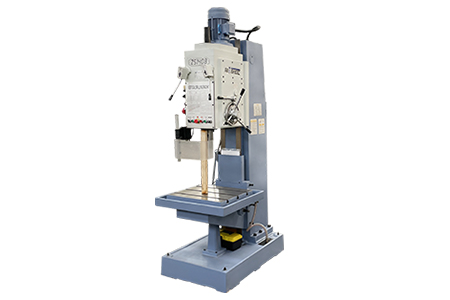

Z5140 5150 vertical drilling machine

Max. drilling diameter : 50mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Drilling machine model | Z5140A | Z5150A |

| Maximum drilling diameter (mm) | 40 | 50 |

| Maximum feed resistance of spindle (N) | 16000 | 16000 |

| Spindle torque (N.m) | 350 | 350 |

| Main motor power (kw) | 3 | 3 |

| Taper of main cone (NO) | 4 | 5 |

| Spindle speed (r.p.m) | 31.5-1400(12 pole) | 31.5-1400(12pole) |

| Spindle feed per revolution (mm/rev) | 0.056 -1.80(9 pole) | 0.056 -1.80(9 pole) |

| Spindle stroke (mm) | 250 | 250 |

| Spindle box stroke (mm) | 200 | 200 |

| Spindle span (mm) | 335 | 335 |

| Workbench stroke (manual) (mm) | 300 | 300 |

| Distance from spindle end to worktable (mm) | 750 | 750 |

| Work table size (mm) | 480×560 | 480×560 |

| Machine weight (kg) | 1250/1350 | 1250/1350 |

| Outline dimension (mm) | 1009×900×2530 | 109×900×2530 |

| Package size (mm) | 1410×1140×2620 | 1410×1140×2620 |

Resources & Downloads:

Z5140 5150 vertical drilling machine Product Introduction :

Product Description

The Z5140 vertical drilling machine is a square column vertical drilling machine. The Z5140 vertical drilling machine has the characteristics of stable structure and convenient installation. A series of design concepts such as the design structure of the Z5140 vertical drilling machine and the power of the high-power spindle motor determine that this type of drilling machine can perform high-intensity drilling operations. The Z5140 vertical drilling machine has a wide range of variable speeds, a large number of feed stages, and a large range from the spindle end to the worktable surface. It can adapt to the production and processing of different workpieces, different materials, and different processing tools. The 40 vertical drilling machine can meet the needs of various processes such as drilling, tapping, expanding, reaming, and countersinking. The production and processing needs of special machines can be carried out by the installation of special fixtures and tools.

Product Features

● The high-power spindle motor, the spindle taper is Morse 4, the spindle power is good, the torque is large, and the large-aperture drilling is guaranteed;

● The bed is cast with resin sand mold, and the basic materials are good, ensuring the long-term stability and durability of the machine tool;

● The main body of the machine tool is heat-treated to eliminate internal stress, and the precision of the guide rail surface ultrasonic quenching is good;

● Spindle speed change, wide feed speed range, suitable for processing and production of multi-workpiece material cutting tools;

● The supporting parts of the machine tool are selected from domestic brand manufacturers, and the good basic parts ensure the long-term precision operation of the machine tool;

● The overall design of the operating handle of the machine tool combines ergonomics, convenient operation, low labor intensity, and high efficiency;

● Wide range of processing materials, multi-process processing and production such as drilling, tapping, reaming, expansion and countersinking can be carried out;

● The main shaft adopts the turbine coupling to ensure the resistance, the main shaft resistance exceeds 2000kg, and the coupling slips to ensure the stable operation of the main shaft.

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life