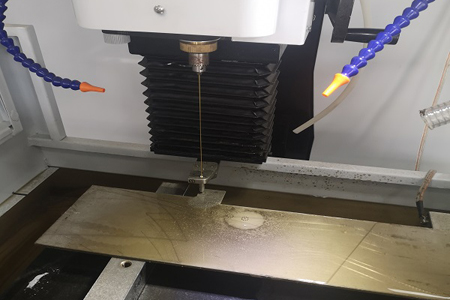

ZNC EDM Hole Drilling Machine

Work surface size : 750X880mm

Work surface travel : 400X600mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Technical Items | DD703(Non-CNC) | ZNC703(3040) | ZNC703(4050) | ZNC703(4060) |

| Work surface size | 420*360mm | 330X480mm | 630X480mm | 750X880mm |

| Work surface travel | 300*400mm | 300X400mm | 400X500mm | 400X600mm |

| Spindle head stroke | 300mm | 400mm | 400mm | 400mm |

| Processing depth | 300mm | 300mm | 300mm | 300mm |

| Electrode diameter | 0.3-3.0mm | 0.3-3.0mm | 0.3-3.0mm | 0.3-3.0mm |

| Max processing speed | 40-60mm/min | 40-60mm/min | 40-60mm/min | 40-60mm/min |

| Spindle speed | 20-120RPM | 20-120RPM | 20-120RPM | 20-120RPM |

| Maximum aspect ratio | 300:1 | 300:1 | 300:1 | 300:1 |

| Working fluid | Pure water | Pure water | Pure water | Pure water |

| Work pressure | 7Mpa | 7Mpa | 7Mpa | 7Mpa |

| Maximum machining current | 30A | 40A | 40A | 40A |

| Maximum power consumption | 3KW | 3KW | 3KW | 5KW |

| Control method | Z-axis Electric Drive | Z-axis automatic | Z-axis automatic | Z-axis automatic |

| Workbench capacity | 250-300kg | 250-300kg | 250-300kg | 250-300kg |

| Working fluid tank capacity | 30L | 30L | 30L | 30L |

| Machine tool power supply | 380V/50Hz/3PH | 380V/50Hz/3PH | 380V/50Hz/3PH | 380V/50Hz/3PH |

| Secondary stroke control method | Electric Drive | Electric Drive | Electric Drive | Electric Drive |

| Digital display | 2-axis DRO

(3-axis optional) |

3-axis DRO | 3-axis DRO | 3-axis DRO |

| Water pump | High pressure pumps | High pressure pump | High pressure pump | High pressure pump |

| Z-axis CNC depth-fixing function | NO | YES | YES | YES |

| Servo stroke | 300mm | 400mm | 400mm | 400mm |

| Machine size (length × width × height) | 900x1200x1850mm | 900x1200x1900 mm | 1800×1500×1700 mm | 1800×1500×1700mm |

| gross weight | 700kg | 750 kg | 1700 kg | 1700 kg |

Resources & Downloads:

ZNC EDM Hole Drilling Machine Product Introduction :

Product Details:

This machine is a high-speed EDM small hole machining equipment, using copper tube as electrode, guided by guide, applying high-efficiency pulse power supply between electrode and work-piece. A pulsed high-frequency discharge is generated between the work-piece and the work-piece, and the work-piece is eroded in a controlled manner. During processing, the high-pressure water quality working fluid is sprayed from the inner hole of the electrode, and the forced chip cooling is performed on the processing area to ensure the smooth progress of the processing.

EDM punching machine is suitable for processing various conductive materials such as stainless steel, hardened steel, cemented carbide, copper and aluminum. This machine tool can be used to process threading holes for fast-travel wire cutting, oil injection holes for oil nozzles and oil pumps, spinneret holes for chemical spinnerets, oil passage holes for hydraulic and pneumatic components, filter plates, group holes for sieve plates, and holes in engines. The deep and small holes that are difficult to be processed by various traditional processing methods such as cooling and cooling holes, this machine tool has a large number of users at home and abroad.

Features:

◆It can process the hole diameter of Φ0.3~Φ3.0mm, and the maximum depth-diameter ratio can reach more than 300:1.

◆The processing speed can reach 5-40mm per minute, the servo stroke is 400, the super long electrode tube can be used, and the electrode tube can be saved by 15%.

◆It can process various conductive materials such as stainless steel, quenched steel, cemented carbide, copper, aluminum, etc.

◆It can be directly penetrated from inclined surface and curved surface.

◆Servo lift adopts double linear guides and electric lift, which ensures the processing accuracy and speed of the product.

◆The spindle adopts two-speed control mode, so that the retracting speed is twice as fast as the processing speed, and the processing is closely tracked to achieve efficient and stable processing of fine electrodes.

◆The bed is equipped with a water pump pressure observation window, which makes it more convenient and simple to observe and adjust the water pump pressure, and the high-pressure water pump processing is more stable.

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life