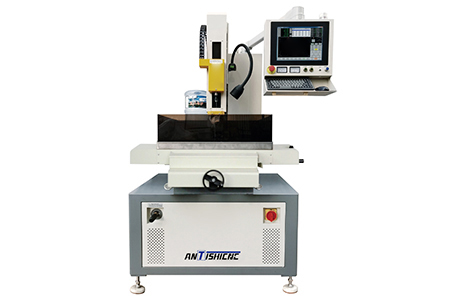

MS-DC430 CNC EDM Drilling Machine

Max. speed of spindle: 1500mm

Spindle rotation speed: 0-200rpm adjustable

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| NO. | Specifications | MS-DC430A | MS-DC430B | MS-DC430C |

| 1 | Electrode diameter(mm) | Φ0.1-Φ3.0 | Φ0.2-Φ3.0 | Φ0.3-Φ3.0 |

| 2 | W axis/ Machine head travel(mm) | 250 | 250 | 250 |

| 3 | Z axis/ Spindle servo travel(mm) | 380 | 380 | 380 |

| 4 | Max. speed of spindle(mm) | 1500 | 1500 | 1500 |

| 5 | Spindle rotation speed(rpm) | 0-200 adjustable | 0-200 adjustable | 0-200 adjustable |

| 6 | Worktable size(mm) | 440*320 | 440*320 | 440*320 |

| 7 | X*Y travel(mm) | 400*300 | 400*300 | 400*300 |

| 8 | Max distance from guide to working table(mm) | 300 | 300 | 300 |

| 9 | Max. worktable load(kg) | 300 | 300 | 300 |

| 10 | Overall dimension of machine(W*L*H) | 1000*1000*2000 | 1000*1000*2100 | 1000*1000*2100 |

| 11 | Machine weight(kg) | 750 | 750 | 750 |

| 12 | Positioning accuracy X,Y(mm) | X.Y≤0.04/300 | X.Y≤0.04/300 | X.Y≤0.04/300 |

| 13 | Repositioning accuracy XY(mm) | X.Y≤0.04/300 | X.Y≤0.04/300 | X.Y≤0.04/300 |

| 14 | Max feed speed XY(mm/min) | ≤1000 | ≤1000 | ≤1000 |

| 15 | Control axes | X、Y、Z three axis | X、Y、Z three axis | X、Y、Z three axis |

| 16 | Machining axis | Z axis | Z axis | Z axis |

| 17 | Max. working current(A | 30 | 30 | 30 |

| 18 | Machining speed(mm/min) | 30-60 | 30-60 | 30-60 |

| 19 | Max. input power(KW) | 4.5 | 4.5 | 4.5 |

| 20 | Min. wear of electrode | ≤0.8 | ≤0.8 | ≤0.8 |

| 21 | Working liquid supply device | Pneumatic pump + electrical pump | electrical pump | electrical pump |

| 22 | Display axis | Three axes | Three axes | Three axes |

| 23 | Capacity(L) | 110 | 110 | 110 |

| 24 | Filtering | Carbon steel paper filtration system | Carbon steel paper filtration system | Carbon steel paper filtration system |

| 25 | Quantity of filter | 1 pieces | 1 pieces | 1 pieces |

| 26 | Material | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel |

| 27 | N.W.(kg) | 45 | 45 | 45 |

| 28 | Dimension (W*L*H) | 920*460*800mm | 920*460*800mm | 920*460*800mm |

Resources & Downloads:

MS-DC430 CNC EDM Drilling Machine Product Introduction :

Main performance characteristics of the machine:

1. Z axis travel is 380mm, up to 500mm-long electrode can be clamped, which reduces the electrode consumption to the minimum (about 100mm); together with super low consumption circuits, the electrode is used at extremely high efficiency.

2. Z-axis uses subdivision drive stepper motor (hybrid servo motor), making high speed movement possible, the whole travel only takes 10 seconds, greatly reducing waiting time and improving efficiency. The machine head is electrically driven.

3. Patented swivel head: innovated design of integrated swivel head with tungsten steel wear plate and multi-layer waterproof structure. The swivel head and chuck is connected by taper sleeve, thus to guarantee rotational concentricity.

4. Patented swivel head: innovated design of integrated swivel head with tungsten steel wear plate and multi-layer waterproof structure. The swivel head and chuck is connected by taper sleeve, thus to guarantee rotational concentricity.

5. Humanized design is shown not only in details of hardware, but also in practical functions of software and user experience.

Main performance characteristics of CNC system

1. The system uses a touch screen industrial computer, Win7 operating system, fast running speed, and can process massive amounts of data at the same time.

2. With rich data interfaces, the system can directly load and edit data through U disk, network port, and wireless, so as to generate the most reasonable processing route.

3. With rich data interfaces, the system can directly load and edit data through U disk, network port, and wireless, so as to generate the most reasonable processing route.

4. System has an expert processing database, it just needs to input the workpiece material, electrode diameter, processing requirements and other conditions, the processing parameters are automatically loaded, and the hole processing parameters can also be adjusted manually.

5. With automatic centering, automatic edge finding, and automatic finding of the surface of the workpiece.

6. Precise depth control, automatic detection of electrode loss, and manual setting of electrode loss.

7. Automatic penetration detection, and depth coordinates can also be set manually.

8. The XY axis has a closed loop function, which can achieve high-precision positioning.

9. XYZ three-axis precision ball screw, Taiwan HIWIN linear guideway.

10. Manual/automatic integrated processing mode, automatic locking after X, Y axis positioning, and manual unlocking.

11. Support 3B, NC, TXT, DXF, ISO and other file formats.

12. It has the function of segmented processing, which can realize the lamination processing of different materials。

13. It can automatically extract circles with different radius in CAD files.

14. High-frequency automatic limit function can make the perforated surface without burnt marks。

15. with automatic electrode repair function。

16. Power foffer memory function, automatic stop function at the end of processing and automatic pause control during machining.

17. (Warning) In order to ensure the quality of the hole diameter, manual processing is selected for electrode tubes with specifications below 0.3mm.

| No. | Spare parts |

| 1 | X Y Z ball screw |

| 2 | W axis ball screw |

| 3 | X Y Z linear guideway |

| 4 | X Y Z motor |

| 5 | X Y driver |

| 6 | Z drier |

| 7 | W axis motor |

| 8 | Rotation motor |

| 9 | electrical pump |

| 10 | Pneumatic pump |

| 11 | scale |

| 12 | operating system |

| 13 | Circuit breakers, contactors |

| 14 | Allen key |

| 15 | Double-head screwdriver |

| 16 | Specialized electrode scissors |

| 17 | Guide |

| 18 | Guide |

| 19 | Brass electrode tube |

| 20 | Brass electrode tube |

| 21 | Electrode sealing ring |

| 22 | Precision drill chuck |

| 23 | Machine foot |

| 24 | Clean water tank |

| 25 | Dirty water tank |

| 26 | Balance holder |

| 27 | Water baffle |

| 28 | Operation Manual |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life