Sawing machine

Milling Machine

Grinding Machine

Lathe Machine

Drilling machine

EDM/WEDM Machine

Laser Cutting Machine

Slotting Shaping Machine

Metal Forming Equipment

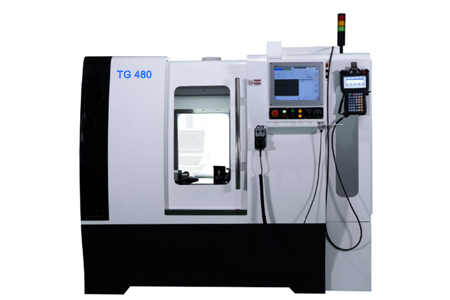

4-Axis TG480 Four-Axis linkage CNC Tool Grinder

Warranty : 1 Year for machinery warranty

Availability : On Stock

WhatsApp : +86-19534031668

Wechat : +86-19534031668

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Item | UNIT | Machine Model:TG480 |

| Linear shaft | – | CNC four-axis linkage linear axis |

| Drive | – | Top class Servo motor drive |

| Stroke (X/Y/Z axis) | mm | 240/300/190 |

| CNC resolution (X/Y/Z/A-axis) | mm | 0.0001 |

| Programming and handwheel feed minimum resolution (X/Y/Z/A-axis) | mm | 0.0001 |

| THK Screw (X/Y/Z axis) | – | BN-FN25-C3 |

| THK Guideway (X/Y/Z axis) | – | SHS-25V (level P) |

| Repeatable positioning accuracy(X/Y/Z axis) | mm | 0.003 |

| Workpiece rotation axis(A/B axis) | – | Rotary Axis |

| DD servo drive(A/B axis) | – | Direct drive |

| Rapid traverse(X/Y/Z axis) | m/min | 7.5 |

| Maximum workpiece weight | kg | 5 |

| Linear resolution | mm | 0.0001 |

| Linear Repeat Positioning Accuracy | mm | 0.003 |

| Rotary resolution | mm | 0.0001 |

| Rotary Repeat Positioning Accuracy | degree | 0.001 |

| Spindle power | kw | 15(Optional: 15KW-20 Permanent magnet variable frequency motor) |

| Machine weight | kg | 4000 |

| Total power | kw | ≤30kw |

Product Features:

1. 4-Axis four linkage CNC tool grinder focuses on the production of: standard milling cutter, aluminum processing cutter, acrylic milling cutter, chamfering cutter, tap slotting.

2. Machine tool adopts: multi-station grinding, multi-grinding wheel grinding process, after many years of practical to ensure the quality of tool production, greatly improve the efficiency of tool production.

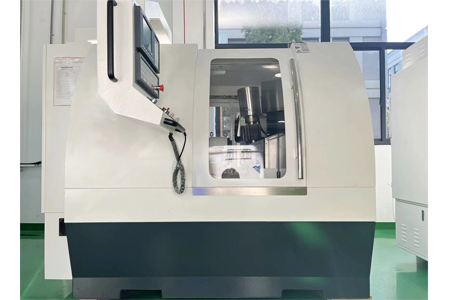

3. Front and rear doors open for unrestricted commissioning and maintenance of the machine tool, and the fully enclosed protective cover meets the production safety.

4. All axes adopt imported servo motors and screw guides, high precision and resolution, to ensure the high production quality and efficiency of the machine tool.

Important parts:

1. X-axis, horizontal linear CNC numerical control axis, China Taiwan-made servo motor, THK precision ball screw, THK precision roller type guide rail.

2. Y-axis, horizontal linear CNC numerical control axis, servo motor made in Taiwan, China, THK precision ball screw, THK precision roller guide.

3. Z-axis, vertical linear CNC numerical control axis, servo motor made in Taiwan, China, THK precision ball screw, THK precision roller guide.

4. A-axis, rotary CNC numerical control workpiece axis, China Taiwan-made servo motor, Japan precision worm gear sets.

5. Z-axis column to increase the angle of the rotary center, the configuration of the angle encoder, to ensure the replacement of different thread angle repeat positioning accuracy, replacement of the size of the adjusting machine is more efficient, more convenient and accurate.

6. Integrated marble bed.

7. Sealed machine cover, easy to adjust the machine, baking paint, the machine can be removed as a whole, easy maintenance.

8. Numerical control operation panel is installed on the machine cover, and the mobile handwheel with magnet is convenient for operation.

9. Special high-speed grooving spindle, can install a piece to three pieces of grinding wheel, can be disassembled as a whole to the grinding wheel dressing machine to repair the grinding wheel.

10. Side edge, vertical use of high-precision direct-connected spindle from Taiwan, China.

11. Sindle motor frequency conversion speed control.

12. Tube sealed oil-proof fluorescent lamp is installed in the machine.

13. Japan FUJIKOSHI, robot automatic loading and unloading mechanism installed outside the machine, the growth of robot life. (Optional)

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.