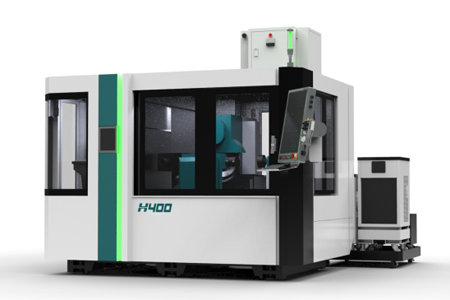

H400 High precision CNC Grinding machine fully automatic insert peripheral grinder

Suitable for carbide, ceramic, CBN, turning tool grinding

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| ITEM | Unit | Machine Model:H400 |

| C Axis | ||

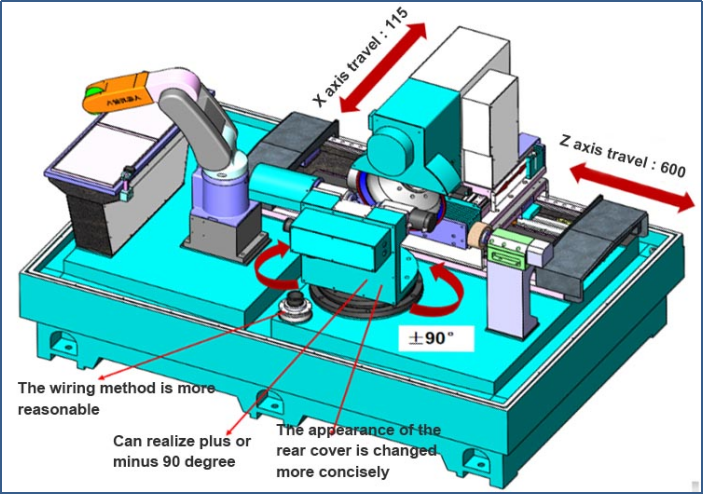

| Stroke | Deg | ∞ |

| Maximum speed | rpm | 500 |

| Positioning accuracy | Deg | 0.006° |

| Repeatability of positioning accuracy | Deg | 0.001° |

| X Axis | ||

| Stroke | mm | 115 |

| Rapid feed rate | mm/min | 10000mm/min |

| Cutting feed rate | mm/min | 0~3600mm |

| Positioning accuracy | mm | 0.005 |

| Repeatability of positioning accuracy | mm | 0.002 |

| Z Axis | ||

| Stroke | mm | 600 |

| Rapid feed rate | mm/min | 10000mm |

| Cutting feed rate | mm/min | 0~3000 |

| positioning accuracy | mm | 0.01 |

| Repeatability of positioning accuracy | mm | 0.005 |

| B Axis | ||

| Stroke | Deg | -90°~+90° |

| Rapid feed rate | °/s | 200 |

| Cutting feed rate | °/s | 0~90° |

| Repeatability of positioning accuracy | Deg | 0.002° |

| Grinding wheel shaft parameters | ||

| Wheel diameter | mm | 400 |

| Rotating speed | rpm | 0~4000 |

| power | Kw | 7.5 |

| Offline trimmer | ||

| Wheel diameter | mm | 150 |

| Maximum speed | rpm | 8000 |

| Power | KW | 0.8 |

| Online dresser (optional) | ||

| Wheel diameter | mm | 150 |

| Maximum speed | rpm | 8000 |

| Stroke | mm | 0~63 |

| Dressing feed rate | mm/min | 0~720 |

| Shaft power | Kw | 0.8 |

| Processing parameters ( different specifications need to replace tooling) | ||

| Maximum thickness | mm | 35 |

| Maximum diameter | mm | φ50 |

| C-axis tooling clamping (depending on the product can be enlarged) | ||

| Clamp force | N | 200~2500 |

| Installed Capacity | ||

| Total power | KW | 25 |

| Size (length*width*height) | mm | 3400*3600*1900 |

| Oil cooling filter device size (optional) | mm | 1800*1200*1500 |

| Machine weight | kg | 7500 |

Resources & Downloads:

H400 High precision CNC Grinding machine fully automatic insert peripheral grinder Product Introduction :

Product description :

H400 peripheral grinder machine is a four-axis CNC grinding machine center, which is mainly suitable for the grinding of grooving and cutting tools of materials such as cemented carbide, ceramic and CBN. It adopts advanced numerical control system, and can realize loading and unloading by six-axis robot, which can realize various angle rotation, reducing blade turning process, further improving efficiency and shortening grinding time. The grinding of various standard and non-standard tools can also be realized by changing the tooling.

Optional Equipment

Centralized filtration system

Oil mist purifier

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life