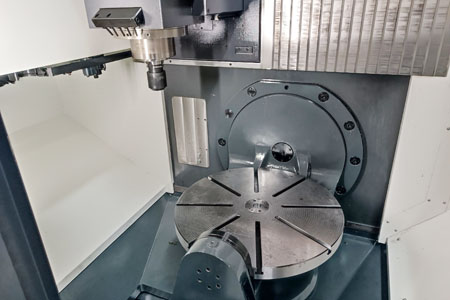

BMC-630V 5 Axis Vertical Machining Center

Table diameter : Ф630 mm

X/Y/Z axis : 600/450/400 mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Name | BMC-630V | |

| Workbench | Table diameter (mm) | Ф630 |

| Allowable maximum horizontal load (kg) | 500 | |

| Maximum allowable vertical load (kg) | 300 | |

| B-axis swing angle (Deg) | -35°~-110° | |

| Table T-slot (slot number X slot width) | 8x14H8 | |

| The distance between the work surface and the ground (mm) | ||

| Processing range | X-axis (mm) | 600 |

| Y-axis (mm) | 450 | |

| Z axis (mm) | 400 | |

| Distance from spindle end face to work table (mm) | 150-550 | |

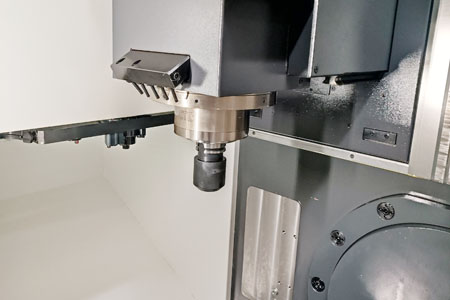

| Spindle | Spindle maximum speed (r/min) | 12000 |

| Spindle rated speed (r/min) | 1500 | |

| Spindle motor power (kW) | 11/15 | |

| Spindle torque (Nm) | 70/95 | |

| Cone hole | BT40 | |

| Feed | Guide | Roller Linear Guide |

| Feed motor power X/Y/Z (kW) | 2.3/2.3/2.3 | |

| Rapid feed rate X/Y/Z (m/min) | 36/36/36 | |

| Turntable maximum speed B/C axis (r/min) | 80/80 | |

| Cutting feed rate X/Y/Z (mm/min) | 20000 | |

| Cutting feedrate B/C axis (r/min) | 50 | |

| Tool device | Number of tools to accommodate (pieces) | 24 (disc) |

| Tool exchange method | manipulator | |

| Tool selection method | Two-way nearest knife selection | |

| Maximum tool weight (kg) | 8 | |

| Maximum tool diameter (mm) (full tool / adjacent empty) | 80/120 | |

| Maximum tool length (mm) | 300 | |

| Shank type | MAS403 BT40 | |

| Pull stud type | MAS403 BT40-1 | |

| Tool change time (T-T) (s) | 1.8 | |

| Precision

|

Positioning accuracy X/Y/Z (mm) | 0.010 |

| Positioning accuracy B/C axis | 10〃/10〃 | |

| Repeated positioning accuracy X/Y/Z (mm) | 0.008 | |

| Repeated positioning accuracy B/C axis | 6〃/6〃 | |

| Other | CNC system | Siemens |

| Air source (MPa) | 0.5 | |

| Power (kW) | 35 | |

| Machine weight (kg) | 6000 | |

| Machine tool dimensions (mm) | 2400×3500×2850 | |

Resources & Downloads:

BMC-630V 5 Axis Vertical Machining Center Product Introduction :

Product Description

The BMC-630V five-axis vertical machining center adopts a stable C-shaped structure and is equipped with a high-speed electric spindle, direct-drive CNC turntable and servo tool magazine as standard. Automotive motors, gearboxes, engines, molds, robots, medical equipment and other manufacturing industries.

Structural form and technical characteristics of key and important components

– Siemens 840D CNC system (five-axis linkage), Siemens 828D CNC system (four-axis linkage);

– Five-axis simultaneous milling, precision cutting of complex parts, one-time clamping, reducing workload;

– B and C turntables have double direct drive rotary shafts, built-in high torque torque motors, high precision, high dynamic response, good precision retention, and a maximum load of 500kg;

– The milling spindle adopts BT40/HSKA63 electric spindle, the spindle speed reaches 12000/18000r/min, and the torque is 70Nm, which greatly improves the processing efficiency and processing accuracy, and reduces the noise and vibration of the machine tool;

– Adopt 24 disc tool magazine, hydraulic synchronous tool change technology, compact structure, reliable performance and rapid tool change;

– Precision high-speed roller guides, ball screws, and imported screw bearings ensure the rigidity and precision of the machine tool;

– Built-in double screw chip conveyor, external chain chip conveyor, with iron filing box;

– Rotary operation panel and handheld MPG make the operation more convenient;

– The front protective door can be fully opened, which is convenient for workpiece lifting and clamping;

Acceptance execution standard and main accuracy

GB/T20957.4 (ISO10791-4) Vertical Machining Center: Accuracy Inspection

– X/Y/Z axis positioning accuracy: 0.01mm

– X/Y/Z axis repeat positioning accuracy: 0.008mm

– B/C axis positioning accuracy: 14″

– Repeated positioning accuracy of B/C axis: 8″

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life