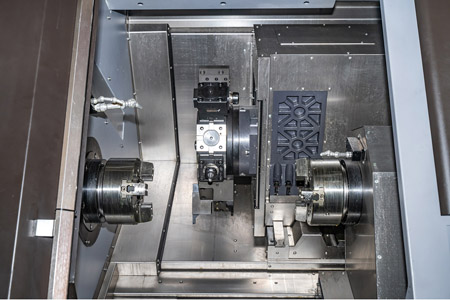

CTX200S Turning and Milling Compound CNC lathe Machine

Max. swing over bed : Φ700mm

Swing over cross slide : Φ300mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Specifications | Units | CTX200S | |

| Max. Swing over bed | mm | Φ700 | |

| Swing over cross slide | mm | Φ300 | |

| Maximum shaft length | mm | 450 | |

| Maximum disk processing diameter | Φ300 | ||

| Maximum turning length | mm | 450 | |

| Spindle | Spindle end type | A2-6 | |

| Spindle through hole diameter | mm | Φ66 | |

| Bar diameter | mm | Φ50 | |

| Hydraulic chuck | Inch | 8 | |

| Hydraulic chuck tie rod through hole | mm | Φ50 | |

| Spindle taper hole taper | No | MT6# | |

| Spindle limit speed | rpm | 4000rpm | |

| Sub-spindle | Spindle end type | A2-6 | |

| Spindle through hole diameter | mm | Φ66 | |

| Bar diameter | mm | Φ50 | |

| Hydraulic chuck | Inch | 8 | |

| Hydraulic chuck tie rod through hole | mm | Φ50 | |

| Spindle taper hole taper | No | 70/1:20 | |

| Spindle limit speed | rpm | 4000rpm | |

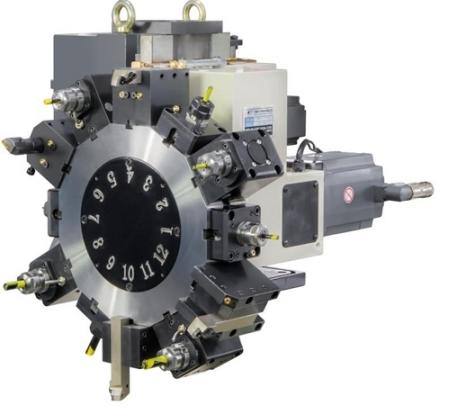

| Tool | Model | TYCSDY80HP-12T

Powered turret |

|

| Tool holder model | BMT55 | ||

| Y axis travel | mm | ±45 | |

| Power motor torque | N.m | 15 | |

| Y-axis motor torque | N.m | 6 | |

| Lead screw model | X direction | 3210 | |

| Z direction | 4010 | ||

| Z2 direction (sub-spindle) | 4010 | ||

| Guide rail model | X direction | RGH35HA | |

| Z direction | RGH45CA | ||

| Z2 direction (sub-spindle) | RGH45CA | ||

| X/Z/Z2 motor torque | N.M | 15/15/15 | |

| X/Z/Z2 direction rapid movement speed | m/min | 18/18/18 | |

| X-direction travel | mm | 200 | |

| Z-direction travel | mm | 520 | |

| Minimum setting unit | mm | 0.001 | |

| Main motor power | KW | 11 | |

| Total power | KW | 32 | |

| Machine tool net weight | Kg | 4200 | |

| Overall dimensions (length × width × height) | mm | 4250*2000*2200 | |

Resources & Downloads:

CTX200S Turning and Milling Compound CNC lathe Machine Product Introduction :

Product Description:

The workpiece clamped one time could finish all processing steps.

This machine tool has the high speed, the high precision, and the strong composite processing ability.

It can process various large and long workpieces.

It can be widely used in various industries such as aviation, energy, shipbuilding, and medical treatment. The modular concept and the highly versatile options provide a wide range of machining possibilities, and achieve machining from universal turning to complex parts complete machining.

Features:

Taiwan roller type linear guide

Higher speed spindle unit

High power Y-axis motor

Embedded lubrication system

High rigidity integral inclined bed

| Spindle |  |

The spindle adopts a high-precision spindle bearing set and has been precision assembled and dynamically balanced tested to ensure high spindle accuracy, low noise and strong rigidity. |

| Tool holder |  |

The tool changing speed is fast and the positioning accuracy is high.

Commonly used is a Y-axis powered turret. |

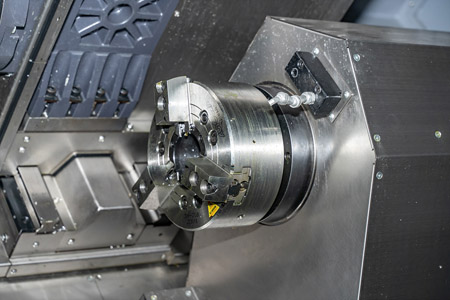

| Chuck |  |

The wedge-shaped through-hole chuck can quickly clamp and loosen the workpiece under the action of hydraulic pressure, with fast clamping speed and high precision. |

| Machine transmission |

|

The screws and nuts are processed, ground, assembled and quality controlled in a constant-temperature workshop to ensure their high-precision stability. The linear rail has a small friction coefficient, fast movement speed and high precision. |

| Sub-spindle |  |

The electric spindle uses a high-precision spindle bearing set and has been precisely assembled and dynamically balanced to ensure high spindle accuracy, low noise and strong rigidity. |

| Machine tool lubrication |  |

Volumetric lubrication pump, automatic lubrication, mainly bed guide rails and

The lubricating surface between the ball screw and nut is continuously supplied with oil. |

| Name | Specifications | Quantity | Supplier | |

| Control System | SYNTEC | 1 set | SYNTEC | |

| Spindle motor | 11KW | 1 set | SYNTEC | |

| Spindle unit | HN200 | 1 set | China | |

| Guide | X direction | 1 set | 1 set | HIWIN/PMI |

| Z direction | RGH45CA | 2 sets | HIWIN/PMI | |

| Ball screw | X direction | 3210 | 1 set | HIWIN |

| Z direction | 4010 | 2 sets | HIWIN | |

| Tool | TYCSDY80HP-12T | 1 set | China | |

| Automatic lubrication device | RBCLB-3ZK | 1 set | China | |

| cooling pump | 550W | 1 set | China | |

| hydraulic station | 1.5kw | 1 set | China | |

| Hydraulic chuck | KT08-3/A2-6 | 2 sets | Taiwan-China | |

| Chip conveyor | Chain plate type | 1 set | China | |

Optional accessories

| Name | Specifications | Quantity |

| Control System | Siemens/Fanuc | 1 set |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life