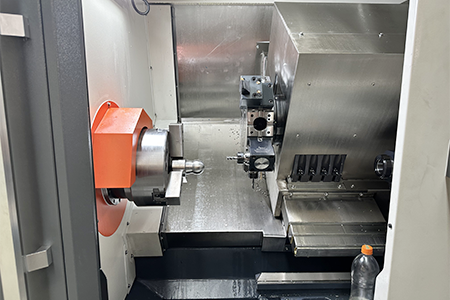

TCK50A-500 Slant Bed CNC Turning milling Lathe Machine

Max. Swing over bed: 560mm

Swing over cross slide: 300mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Specifications | Units | TCK50A/500 |

| Max. Swing over bed | mm | 560 |

| Swing over cross slide | mm | 300 |

| Max. disc machining diameter | mm | 300 |

| Max. turning length | mm | 400 |

| Spindle end type | A2-6 | |

| Spindle through hole diameter | mm | Φ66 |

| Bar diameter | mm | Φ55 |

| Hydraulic chuck | mm | 10 inch |

| Hydraulic chuck pull rod through hole | mm | 55 |

| Rail form | Linear Guides | |

| Spindle taper taper | No | Metric 70 1:20 |

| Spindle limit speed | rpm | 3000rpm

Infinitely variable speed |

| Cutting feed rate | mm/min | 1-15000 |

| Powered Turret Specifications | TCSDY80H-12T-330 | |

| Turret tool holder | BMT55 | |

| Tail-stock sleeve diameter | mm | 70 |

| Tail-stock sleeve inner hole taper | No | Mohs 5# |

| Tail-stock sleeve stroke | mm | 80 |

| Tail-stock maximum travel | mm | 450 |

| Powered tool turret chuck | mm | ER20 |

| Tool post/Turret | Position | 8 |

| Tool square size | mm | 25´25 |

| Maximum boring tool diameter | mm | Æ32 |

| X/Z direction motor torque | NM | 15/15 (X direction with brake) |

| X/Z rapid traverse speed | m/min | 18/18 |

| X travel | mm | 240 |

| Z travel | mm | 500 |

| Y travel | mm | ±45 |

| Total power capacity | KVA | 24 |

| Cutting water tank capacity | L | 90 |

| Main motor power | KW | 11 |

| Machine net weight | Kg | 3400 |

| Dimensions (L×W×H) | mm | 2700*2000*2000 |

Resources & Downloads:

TCK50A-500 Slant Bed CNC Turning milling Lathe Machine Product Introduction :

Product description

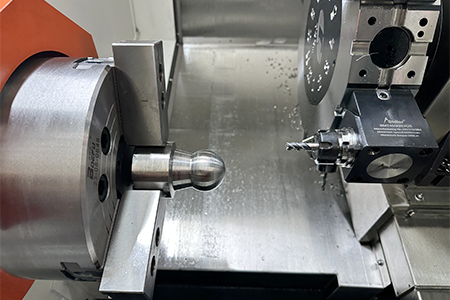

The TCK Series High Precision CNC Turning Center Slant Bed product is a semi-closed slant-bed turning and milling machine with X, Y, Z and C axes servo control. The structure and external dimensions are compact and reasonable. The spindle (C axis) is driven by a servo motor. It can realize the turning of the outer circle, the end surface and the thread of various materials, such as shafts and discs, and various surface milling and drilling in radial and axial directions, and is suitable for efficient machining of small parts.

Features

1.The inclined guide rail is mainly used to overcome gravity and have better stability to improve the precision of the machine tool

2.The inclined machine tool can effectively utilize the space and greatly reduce the plane occupied by the machine tool.

3.The inclined guide rail also facilitates the concentration of iron chips on the chip conveyor for automatic chip removal.

Standard Equipment

| Name | Specifications | Quantity | Supplier |

| CNC System | GSK988T | 1set | GSK-China |

| Spindle motor | Servo main motor (11 KW) | 1set | GSK-China |

| Spindle unit | Φ200 | 1set | China |

| Screw bearing | 25TAC62 | 1 set each | NSK/KoYo-Japan |

| Tool post/Turret | 12 stations (BMT55) | 1set | Taiwan-China |

| Powered tool holder | ER20 | 2 pcs | China |

| Powered tool holder | ER16 | 2 pcs | China |

| X/Z roller guide | 35/35 | 1set | HIWIN/PMI-China |

| X/Z ball screw | 3210/4010 | 1set | HIWIN/PMI-China |

| Automatic lubricating device | – | 1set | China |

| Cooling pump | 370W | 1set | China |

| Hydraulic station | 2.2kw | 1set | China |

| Hydraulic chuck | 10” | 1set | China |

| Hydraulic tailstock | – | 1set | China |

Optional accessories

| Name | Specifications | Quantity |

| Control System | FANUC/Siemens | 1 set |

| Chip conveyor | Chain plate type | 1 set |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life