Sawing machine

Milling Machine

Grinding Machine

Lathe Machine

Drilling machine

EDM/WEDM Machine

Laser Cutting Machine

Slotting Shaping Machine

Metal Forming Equipment

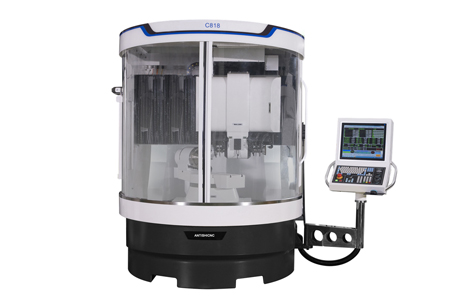

C818 Precision tools 5-axis 5-linkage CNC tool grinder

Warranty : 1 Year for machinery warranty

Availability : On Stock

WhatsApp : +86-19534031668

Wechat : +86-19534031668

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| ITEM DESCRIPTION | UNIT | C818(MINI) | C818(POWER) | C818(VISION) |

| Japan servo motor driver travel ( X/Y/Z axis) | mm | 650/350/270 | 700/450/300 | 800/550/320 |

| CNC system resolution (X/Y/Z-axis) | mm | 0.0001 | 0.0001 | 0.0001 |

| Programming and handwheel feed minimum resolution (X/Y/Z axis) | mm | 0.0001 | 0.0001 | 0.0001 |

| THK screw (X/Y/Z axis) | – | BN-FN32-C3 | BN-FN32-C3 | BN-FN32-C3 |

| Repeatable positioning accuracy (X/Y/Z axis) | mm | 0.003 | 0.003 | 0.003 |

| Guideway (X/Y/Z axis) | mm | MR35-G1/MR35-G1 | SRG45-P/SRG35-P/SRG35-P | MR45-G1/BM35-G1/BM35-G1 |

| Workpiece rotation axis (A/B axis) | – | Rotary Axis | Rotary Axis | Rotary Axis |

| DD servo drive (A/B axis) | – | Direct drive | Direct drive | Direct drive |

| Rotary encoder (A/B axis) | – | RENISHAW UK | RENISHAW UK | RENISHAW UK |

| Indexing accuracy (A/B axis) | – | 2arc sec(0.0005degree) | 2arc sec(0.0005degree) | 2arc sec(0.0005degree) |

| Rated RPM (A/B axis) | rpm | 300/100 | 300/100 | 300/100 |

| Maximum speed (A/B axis) | rpm | 400/150 | 400/150 | 400/150 |

| CNC resolution (A/B axis) | Degree | 0.0001 | 0.0001 | 0.0001 |

| 360 degree rotation, indexing head body (A/B axis) | – | Can Mount Shobelin W25 collet holders & BT50 shanks | Can Mount Shobelin W25 collet holders & BT50 shanks | Can Mount Shobelin W25 collet holders & BT50 shanks |

| Rapid traverse (X/Y/Z axis) | m/min | 7.5 | 7.5 | 7.5 |

| Clamping minimum workpiece diameter | mm | 3 | 3 | 3 |

| Clamping maximum workpiece diameter | mm | 20 | 20 | 20 |

| Clamping maximum workpiece length | mm | 200 | 200 | 200 |

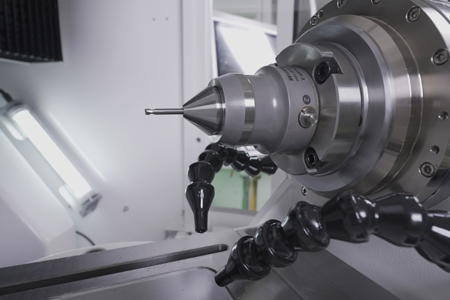

| Grinding minimum workpiece diameter | mm | 1 | 1 | 1 |

| Grinding maximum workpiece diameter | mm | 12 | 12 | 12 |

| Maximum grinding length | mm | ≤120 | ≤180 | ≤180 |

| Maximum workpiece weight | kg | 5 | 5 | 5 |

| Linear resolution | mm | 0.0001 | 0.0001 | 0.0001 |

| Linear repeatability | mm | 0.003 | 0.003 | 0.003 |

| Rotary resolution | mm | 0.0001 | 0.0001 | 0.0001 |

| Rotary Repeat Positioning Accuracy | degree | 0.001 | 0.001 | 0.001 |

| Spindle power(Permanent magnet variable frequency motor) | kw | 12-15kw | 22kw | 30kw |

| Grinding wheel diameter | mm | 75-150 | 75-150 | 75-150 |

| Grinding wheel spindle speed | rpm | 4000-8000 | 4000-8000 | 4000-8000 |

| Infinitely adjustable | – | inverter | inverter | inverter |

| Machine weight | kg | 4000 | 5000 | 6500 |

| Total power | kw | ≤22.5kw | ≤30kw | ≤45kw |

| Selecting optional linear motor upgrade to C828 series is available. | ||||

C818 5-axis 5-linkage CNC tool grinder is used in aerospace, high-speed rail, automotive, medical, IT precision tool grinding and other fields.

Five-axis linkage tool grinder features:

1. C818 5-axis 5-linkage CNC tool grinder adopts integral mineral casting bed, Japan imported servo motor with screw guide (heavy duty roller type), A, B rotary axis high torque DD motor.

2. Permanent magnet constant torque spindle motor, double grinding head structure, B-axis can be rotated 360 degrees, suitable for a variety of non-standard tool processing production.

3. Five-axis five linkage CNC tool special grinding machine, is based on the German five-axis tool grinder concept and design.

4. personnel experience in actual operation, and in the tool production site exchanges and design.

5. It is embodied in practicality, economy, operation, maintenance, stability and high efficiency.

Five-axis linkage CNC tool grinder main accessories:

1. Line rail – Japan THK;

2. Spindle – China Taiwan brand;

3. Light scale – Germany HEIDENHAIN;

4. Division dial – Shengchang, Taiwan, China;

5. Centralized automatic lubrication station – Shengxiang;

6. Circuit accessories electrical – Schneider / Omron;

7. Probe head – British Renishaw RENISHAW;

8. CNC system – SYNTEC China Taiwan new generation;

9. Pneumatic system ( solenoid valve, pressure reducing valve, air filter, etc.) – CHELIC;

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.