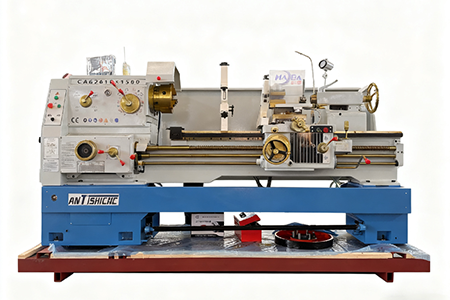

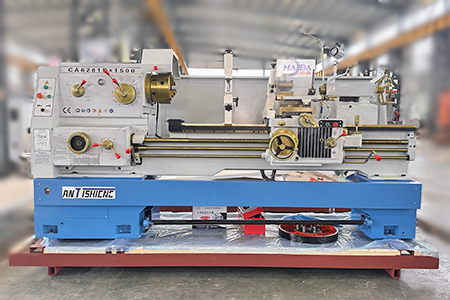

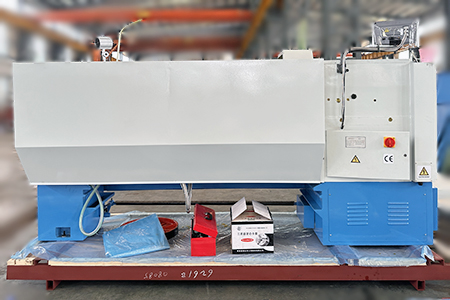

CA6261Bx1500 Lathe Machine

Max swing over bed:Φ610mm

Max swing over slide:Φ370mm

Max workpiece length:1500mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Item | Unit | CA6261Bx1500 | |

| Capacity | Max swing over bed | mm | Φ610 |

| Max swing in gap | mm | Φ830 | |

| Effective length in gap | mm | Φ210 | |

| Max swing over slide | mm | Φ370 | |

| Max workpiece length | mm | 1500 | |

| Maximum weight of workpiece between centers | Kg | 300 kg | |

| Machine bed width | mm | 400 | |

| Spindle | Spindle aperture diameter | mm | Φ80 |

| Spindle nose | ISO (GB) D8 | ||

| Spindle taper | Mohs | No. 6 | |

| Distance from spindle center to bed guide rail | mm | 305 | |

| Spindle speed | r/min | Front:24 step 10-1600r/min

Back:12 step 12.5-1600r/min |

|

| Spindle motor | kW | 7.5 | |

| Tailstock | Quill dia./travel | mm | φ75/150 |

| Taper of center | MT | 5 | |

| Tool post | Number of station/

Tool section |

4/25X25 | |

| Tool post rapid movement speed(longitudinal) | m/min | 4 | |

| Tool post rapid movement speed(Cross) | m/min | 2 | |

| Turret turntable rotation angle | º | ±90º | |

| Feed | Max. Travel of upper toolpost | mm | 140 |

| Max. Travel of lower toolpost | mm | 367 | |

| X-axis feed(standard) | mm/r | 0.04-0.79 | |

| X-axis feed(small feed) | mm/r | 0.014-0.027 | |

| X-axis feed(increase feed) | mm/r | 0.86-3.16 | |

| Z-axis feed(standard) | mm/r | 0.08-1.59 | |

| Z-axis feed(small feed) | mm/r | 0.028-0.054 | |

| Z-axis feed(increase feed) | mm/r | 1.71-6.33 | |

| Metric thread | mm | 44 sorts 1-192 | |

| Inch thread | t.p.i | 21 sorts 2-24 | |

| Module thread | πmm | 39 sorts 0.25-48 | |

| DP thread | DP | 37 sorts 1-96 | |

| Others | Coolant pump motor | W | 90 |

| Cooling water pump head | m | 5 | |

| Cooling water pump flow | L/min | 25 | |

| Overall dimensions of the machine (L × W × H) | mm | 3150×1150×1750 | |

| Packing weight | kg | 2600 | |

Resources & Downloads:

CA6261Bx1500 Lathe Machine Product Introduction :

Equipment Introductions:

The CA6261B conventional horizontal lathe is suitable for turning internal and external cylindrical surfaces, conical surfaces and other rotating surfaces, as well as various metric, imperial, module and diametral pitch threads. It can also perform operations such as drilling and oil groove broaching. As a highly versatile horizontal lathe, it is widely used in the batch processing of various shaft and disc parts. The bed of this series of lathes is wider than that of ordinary lathes, with a guideway width of 400mm, providing high rigidity. The guideway surfaces are subjected to medium-frequency quenching, ensuring long-term wear resistance. The machine tool features convenient and centralized operation. The carriage is equipped with a rapid traversal mechanism, and a single-handle visualized operation is adopted, offering good user-friendliness. Both the structural rigidity and transmission rigidity of the machine tool are higher than those of ordinary lathes, with high power utilization, making it suitable for heavy-duty cutting. Before leaving the factory, the machine tool undergoes strict inspection procedures and a heavy-duty cutting test to ensure it has excellent precision stability and processing reliability.

Standard Equipment:

3-jaw chuck and adapte-250MM

4-station conventional tool post

Mounting pad and foot blot

Dead center Ⅱ5 S25-2

Suitable wrench

Oil gun

Foot brake

Work lamp

Chuck protection

Tool post protection

Foot brake

Full splash guard

Φ30-180 Steady rest

20-80mm Follow rest

Optional Equipment:

Living center

Taper turning attachment

Thread chasing dial

Digital readout(2 AXIS)

Digital readout(3 AXIS)

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life