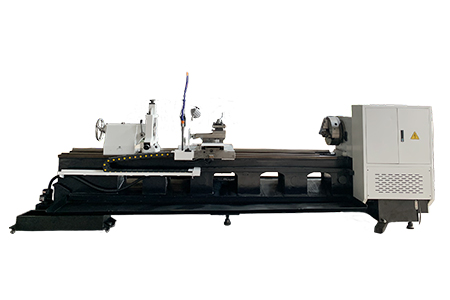

CLD6163 Big bore universal lathe machine

Max swing over bed: f630mm

Max swing over slide: f340mm

Max workpiece length: 3000mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Item | Parameter | Unit | Specifications | Remarks |

| Capacity | Max swing over bed | mm | f630 | |

| Max swing over slide | mm | f340 | ||

| Machine bed width | mm | 550 | ||

| Max workpiece length | mm | 3000 | ||

| Maximum turning length | mm | 2750 | ||

| Spindle | Spindle end form | Screw thread | ||

| Spindle through hole diameter | mm | 150 | ||

| Spindle speed | r/min | 28-700. | ||

| Spindle speed series | 3 gear | |||

| Main motor power | kW | 11 | Spindle servo | |

| Outside diameter of chuck | mm | 400 | Hand three jaw | |

| Tool post | Form | Manual | ||

| Number of stations | 4 | |||

| Tool section | mm | 32×32 | ||

| Feed | X-axis fast moving speed | mm/min | 2300 | |

| Z-axis fast moving speed | mm/min | 4000 | ||

| x-stroke | mm | 320 | ||

| z-stroke | mm | 750 | ||

| X-axis feed series/range | mm/r | 32/0.04-0.65 | ||

| Z-axis feed series/range | mm/r | 32/0.1-1.46 | ||

| Metric thread type/range | mm | 32/1-15 | ||

| Number/range of thread in inch | T.P.I. | 26/14-1 | ||

| Tailstock | Quill dia. | mm | 100 | |

| Quill travel | mm | 250 | ||

| Taper of center | MT | 5# | ||

| Others | Lubrication form | Automatic intermittent lubrication | ||

| Lubrication pump capacity | L | 2 | ||

| Cooling pump head | m | 10 | ||

| Cooling pump flow | L/min | 100 | ||

| Machine weight | kg | 5500 | ||

| Machine tool appearance (LxWxH) | mm | 5100×1500×1400 | ||

| Total electrical capacity | kVA | 12 |

Resources & Downloads:

CLD6163 Big bore universal lathe machine Product Introduction :

Equipment Introductions:

This series of lathe is a general purpose large hole metal cutting machine, suitable for turning internal and external cylindrical, conical and other rotating surfaces, turning various metric and imperial threads, and drilling and pulling oil grooves and other work. This series of machine tools is suitable for processing cast iron, steel and various non-ferrous metals and other materials.

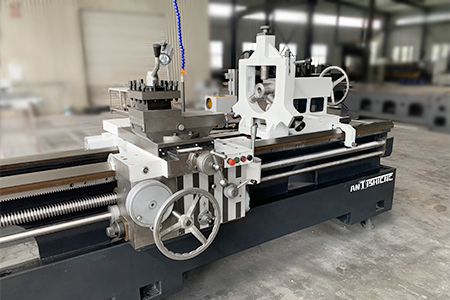

The machine adopts a flat bed oblique structure, easy operation and adjustment, which is conducive to chip removal, high-quality and high-strength cast iron casting the whole bed, good shock absorption, aging treatment, good rigidity, high precision, the width of the bed guide rail is 550mm, the use of ultra-audio quenching and precision grinding and plastering, scraping process, low friction resistance, long precision retention, effectively ensure the accuracy and service life of the machine tool.

The spindle box is an integral gear box type spindle unit, three-speed frequency conversion, stepless transmission in the file, the main motor adopts low-frequency and high-torque spindle servo motor, the output torque is large, the start-stop response is fast, which not only meets the requirements of fine turning, but also can achieve efficient cutting.

The main shaft adopts the quenched precision grinding helical gear transmission structure, which has high transmission efficiency, strong load capacity, more stable transmission, low noise and longer service life of the gear.

Standard Equipment

| Name | Model/Specification | Quantity |

| Main motor | 11kW | 1 set |

| Servo driver | SF200 | 1 set |

| Longitudinal lead screw | 55mm(metric) | 1 set |

| Main shaft bearing | 32938 | 2 sets |

| Tool rest | 192 x 192 | 1 set |

| chuck | K11 400 | 1 set |

| Cooling water pump | 180W | 1 set |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life