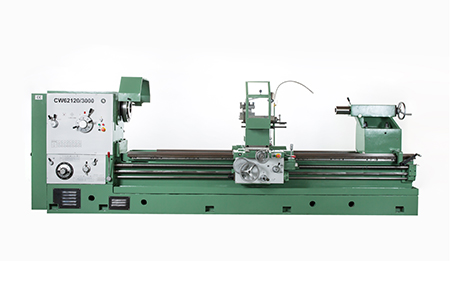

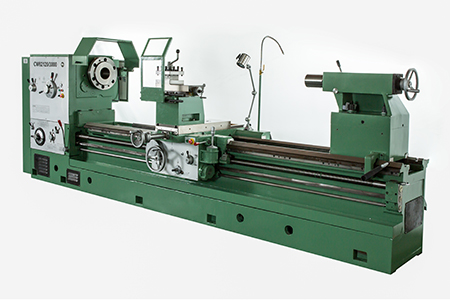

CW62120D/3000 Horizontal flat bed Lathe

Max.Swing Over Bed:1200mm

Max.Swing Over Gap:1400mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Specifications | CW62120D/3000 |

| Max.Swing Over Bed | 1200mm |

| Max.Swing Over Gap | 1400mm |

| Max.Swing Over Cross Slide | 880mm |

| Center Distance | 3000mm |

| Width Of Bed | 600mm |

| Spindle Hole | 130mm |

| Spindle Taper | ∮140mm taper 1:20 |

| Spindle Nose | C-15 |

| Spindle Speeds | 5.5-730r/min(18 Steps) design |

| Metric Threads | 1-240mm (52) |

| Inch Threads | 1-14 (26) TPI |

| Moudle Threads | 0.5-120mm (53) |

| Diametral Threads | 1-28 (24) DP |

| Longitudinal Feeds Range | 0.1-24.3mm/r(64 steps) |

| Cross Feed Range | 0.05-12.15mm/r(64 steps) |

| Rapid Feed:Long/Cross | 4000mm/min,2000mm/min |

| Tool Section | 32*32mm |

| Cross Slide Travel | 500mm |

| Top Rest Travel | 200mm (optional: A-type automatic tool feed stroke is 170mm) |

| Sleeve Diameter | 120mm |

| Sleeve Taper | MT6 |

| Sleeve Travel | 240mm |

| Main Motor | 11kw |

| Rapid feed motor | 1.1kw |

| Machine size | 5500*1800*2100mm |

| Machine weight | 6T |

Resources & Downloads:

CW62120D/3000 Horizontal flat bed Lathe Product Introduction :

Product description

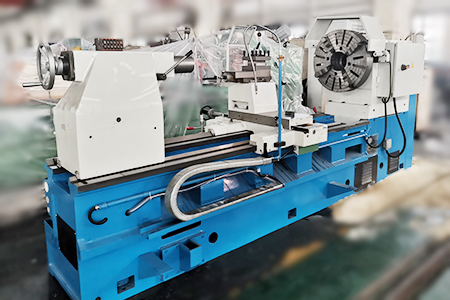

The CW62120Dx3000 lathe can undertake various rough and fine turning processes of ferrous metals, non-ferrous metals and non-metal workpieces, such as turning inner and outer cylindrical surfaces, conical surfaces and other rotating surfaces; it can also turn end faces and various commonly used metric, inch, and Module, pitch thread and multi-start thread, and can be used for drilling, reaming and oil groove pulling on machine tools.

The dimensional accuracy of workpieces processed on this machine tool can reach IT7 level. The roundness error of standard samples is ≤0.01, the cylindricity error is ≤0.03 on a length of 300 mm.

Features

1.Lathe bed

The bed guide rails are two plane guide rails and two diamond guide rails. The front diamond guide rail and the rear flat guide rail are used for the tool rest slide plate, and the remaining guide rails are used for the tailstock and center frame.

The bed of this machine tool is made of high-quality cast iron, and the surface of the guide rails has been quenched to have good wear resistance. The rotary valve that hydraulically controls the forward, reverse and braking spindle rotation is installed on the inner wall of the cavity at the front of the bed, and the spindle control handle is directly connected to the rotary valve.

2.Spindle box

The headboard adopts full gear transmission, and the teeth are all treated by high-frequency quenching. There is a special oil pipe inside the box for oil injection lubrication. The machine tool spindle adopts a three-support rolling bearing structure, and the three supports of the spindle all adopt D-class precision bearings. The accuracy of the spindle system has been carefully adjusted when the machine tool leaves the factory. Because the accuracy of the spindle system directly affects the working performance of the machine tool. Therefore, it is not allowed to be transferred at will. If adjustments are required, the following procedures must be followed.

3.Feed box

The feed box is a two-axis sliding gear mechanism, which is composed of three parts, namely the basic group, the multiplying group and the metric and inch conversion group. According to the instructions on the pitch and feed amount signs on the upper part of the feed box, operating the relevant handles and changing hanging wheels can obtain different pitches and feed amounts of various threads.

4.Cross slide

The feed motion of the machine tool is transmitted by the light rod through the gear on the slide box, the one-way overrunning clutch and the safety clutch consisting of a spiral double-claw end coupling and a cylindrical pressure spring, and then transmitted to the worm through the worm gear and a series of gears. Provide the rack on the bed to realize the longitudinal forward and reverse feed of the tool holder, or transmit the power to the screw rod on the bed saddle to realize the lateral forward and reverse feed of the tool holder.

5.Manual toolholder

The tool rest turntable can rotate 60° left and right relative to the tool rest slide plate 2 to turn cone parts. The bed saddle can move longitudinally along the body guide rail. The longitudinal motorized feed movement and rapid movement can be realized by the transmission of the screw or light rod and the fast-moving motor. The handwheel on the sliding crate can be used to realize longitudinal manual movement.

6.Tailstock

The tailstock of this machine tool can use the tailstock moving handle to move it to the desired position along the bed guide rail. It must be noted that the swing direction of the handle is opposite to the moving direction of the tailstock. Turn the handwheel on the tailstock to move the tailstock sleeve longitudinally. When the tailstock sleeve returns to the body close to the limit position, the end of the screw can push out the tip.

7.Steady rest

The center frame is used as a support when processing slender shaft parts to prevent bending due to cutting force. It can also be used in situations where it is not suitable to use a tailstock support when processing long parts.

The center frame clamping range is φ20~φ300 mm.

The tool rest is a center frame fixed on the slide plate and moves together with the tool rest.

The clamping range with the tool holder is φ20~φ135 mm.

Standard Accessories

| Name | Details | Quantity |

| Drive plate | ¢450 | 1 |

| Three-jaw chuck | ¢400 | 1 |

| Three-jaw chuck sect | 1 | |

| Four-jaw chuck | ¢630 | 1 |

| Four-jaw chuck sect | 1 | |

| Steady rest | Ф100-Ф300mm | 1 |

| Follow rest | Ф20-180mm | 1 |

| Spindle Center | MT6 | 1 |

| Tailstock center | MT6 | 1 |

| Center sleeve | 1 | |

| Chuck protection | 1 | |

| Tool rest protection | 1 | |

| Spanners | 1 | |

| Iron gaskets | 1 | |

| Foundation bolts | 1 | |

| Work light | 1 | |

| Cooling pump | 1 | |

| Thread dial | 1 |

Optional Accessories

| Name | Details |

| Face plate | 1000mm |

| 2-axis DRO | 3m |

| 3-axis DRO | 3m |

| Live center | MT6 |

| Compound slide auto feed |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life