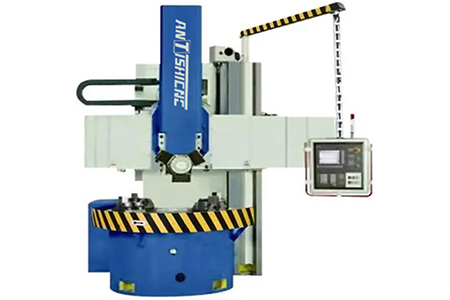

DVT-5112 Single Column Vertical Lathe

Max. workpiece height: 1000mm

Max. workpiece weight: 3.5t

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Specifications | Units | DVT-5112 | |

| Max. cutting diameter of the tool rest | mm | 1250 | |

| Worktable diameter | mm | 1000 | |

| Max. workpiece height | mm | 1000 | |

| Max. workpiece weight | t | 3.5 | |

| Worktable speed range | r/min | 6.2-200 | |

| Worktable speed series | / | 16 Gear type | |

| Max. worktable torque | Kn/m | 25 | |

| Tool rest feed series | Step | Step-less | |

| Max. cutting force of the tool rest | KN | 18 | |

| Ram | Horizontal travel | mm | 700 |

| Vertical travel | mm | 800 | |

| Crossbeam travel | mm | 650 | |

| Tool holder feed range | mm/min | 0.1-500 | |

| Crossbeam lifting speed | mm/min | 440 | |

| Tool bar cross-section size (length*width) | mm | 30×40 | |

| Main motor power | KW | 22 | |

Resources & Downloads:

DVT-5112 Single Column Vertical Lathe Product Introduction :

Product description

DVT system control, equipped with digital display, square ram structure (ram section 200×200mm), 16-speed transmission, main motor AC22KW, crossbeam protection.

DVT51 series program-controlled single-column vertical lathe is a high-tech mechatronic product that our company has absorbed the most advanced contemporary design and manufacturing technology, adopted CAD optimization design methods, implemented enterprise precision standards, and equipped with domestic and foreign advanced functional components. The structural performance has achieved powerful cutting, ultra-heavy load on the worktable, high dynamic and static rigidity of the machine tool, safe and reliable movements, long service life, and high processing efficiency.

Machine tool use:

This machine tool is suitable for high-speed steel tools, carbide tools and various high-performance tools, processing ferrous metals, non-ferrous metals and some non-metallic material workpieces. The machine tool can complete the rough and fine turning of internal and external cylindrical surfaces, planes, internal and external ring grooves and other processes.

Features

This lathe machine consists of a bed, a worktable, a worktable base, a main transmission mechanism, a crossbeam, a vertical tool holder, an electric cabinet, a hydraulic system, a CNC system and other parts.

1.Worktable

The workbench consists of a rotary workbench, a workbench base, a spindle device and a transmission mechanism.

The base adopts a vibration absorption structure design, and uses radial and annular reinforcement ribs, which are arranged reasonably and optimized, so that the base has high strength, rigidity and shock resistance. The base rails are supported by hydraulic rails, and the spindle uses two sets of NN series tapered double-row cylindrical roller bearings for centering. The bearing clearance can be adjusted by pre-tightening the inner ring of the bearing to achieve a higher rotation accuracy. The spindle bearing is lubricated with a large flow of lubricating oil, which improves the accuracy and stability of the machine tool.

2.Machine Bed

The bed is made of high-strength, low-stress cast iron, which is treated with heat aging stress relief annealing and effective vibration reduction measures to ensure that the bed has sufficient rigidity. The guide rail surface of the bed is finely ground, with good contact surface and high precision. The guide rail surface is ultrasonic quenched, with a quenching hardness of HRC48-55.

3.Cross Beam

The beam lifting adopts a worm gear box and a T-type screw lifting mechanism. The beam moves along the column guide rail. There is a hydraulic locking mechanism on the beam. It is clamped by a hydraulic lever wedge block mechanism with a self-locking function, and interlocked with the beam movement to firmly lock the beam on the column. The beam lifting and lowering are equipped with dual mechanical limit and electrical soft limit, which is safe and reliable.

4.Turning tool rest

The tool rest is controlled by the DVT system and consists of a crossbeam slide, a rotary slide, a ram, a balancing cylinder and a ball screw assembly. The horizontal feed is driven by a servo motor through a precision planetary reducer to drive the ball screw to move horizontally. The vertical feed is driven by a servo motor through a precision planetary reducer to drive the ball screw to move vertically. The tool rest ram is equipped with a hydraulic balancing device to balance the weight of the ram and make the ram move smoothly.

5.Main transmission mechanism

The main transmission mechanism is driven by an AC22KW motor to drive the gearbox. The gearbox is controlled by an electromagnetic slide valve to control the speed change cylinder. The speed change fork pushes the speed change gear to achieve 16 gears. The gear is made of 42 chromium-molybdenum high-end quenching treatment, with a hardness of HRC40-45. The tooth surface is ground and the accuracy can reach 6 levels. The gearbox has low noise, large torque transmission, no tooth breakage, and is reliable to use.

6.Operation part

The machine tool is equipped with a suspended main control console, on which an operation panel and all the machine tool operation keys are installed.

7.Hydraulic system

The hydraulic system includes: workbench hydraulic system, main transmission speed change system, beam clamping system, vertical tool holder slide hydraulic balance system. The oil supply system of the workbench guide rail is composed of components such as gear pumps. The oil outlets are connected to the oil chambers respectively. When processing workpieces of different weights, the output flow can be controlled by the flow selection switch to ensure the floating amount of the workbench.

8.Control system

The machine tool adopts DVT system control. The control and mechanical action of the machine tool are interlocked at multiple locations to ensure the reliability and safety of the control and mechanical action of the machine tool. Once a fault occurs, just press the emergency stop button and the whole equipment will be powered off.

9.Electrical part

The electrical control part is completely independently designed, constructed, debugged and provided with after-sales service by our company (not outsourced), which effectively guarantees product quality and solves users’ worries.

The electrical design, manufacturing and installation of machine tools comply with the International Electrotechnical Commission GB5226.1-2008/IEC60204-1:2005, ISO13849-12006 Industrial Machinery Electrical Equipment Part 1 General Technical Requirements.

10.The color of the machine tool is in accordance with the ANTISHICNC production standard. If the user needs to customize the color, please confirm with the Shanghai ANTS Team.

11.Machine tool working environment

(1) The whole machine adopts three-phase AC 380V, plus or minus 10%, 50Hz unified power supply. Work area lighting 220V, 300W. User-provided.

(2) The machine tool working environment temperature is 10-40 degrees Celsius.

(3) The relative humidity of the environment is less than or equal to 85%.

(4) The workshop is free of harmful gases, liquids, and dust.

(5) The user prepares the 46# anti-wear hydraulic oil required for the machine tool.

(6) The installation site should be a standard factory building without vibration sources, dust sources and electromagnetic radiation.

(7) The user prepares consumable low-value consumables, such as detergents, cotton cloth, etc.

Standard Equipment:

| Name | Describe | Quantity |

| Lathe Machine | DVT-5112 | 1 set |

| Chuck Jaw/Cams | With positioning plate | 4 sets |

| Cool pump | / | 1set |

| Digital display/UTI | / | 1 set |

| Toolholder | Tool max.cross-section 40*40mm | 1 set |

| Bracket | / | 8 sets |

| Nut | M24 | 7 sets |

| Washer | 24 | 7 sets |

| Anchor bolts | M24X600 | 7 sets |

| square socket wrench | S=22 | 1 set |

Main parts purchase list:

| NO. | Name | Supplier |

| 1 | AC servo motor and servo drive unit | CTB |

| 2 | PLC programmable controller, position control module | OMRON |

| 3 | Main motor | CHINA |

| 4 | Hydraulic Components | CHINA |

| 5 | Spindle bearings | CHINA |

| 6 | Ball screw | CHINA |

| 7 | Electrical components | Schneider |

| 8 | Ball screw support bearing | ZWZ |

| 9 | PTFE soft belt | CHINA |

| 10 | Centralized lubrication station | CHINA |

| 11 | Planetary reducer | CHINA |

Note: Due to factors such as the procurement cycle, the manufacturer reserves the right to replace purchased parts of the same quality and different brands, but imported purchased parts do not need to be replaced with domestic parts.

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life