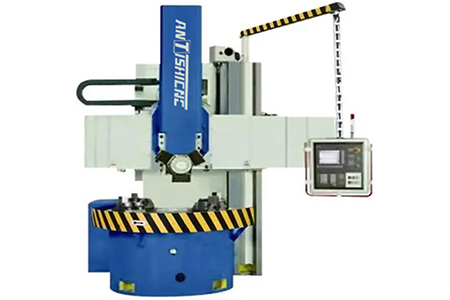

DVT5116D Single-Column Vertical Lathe

Max.height of workpiece: 1600mm

Max.weight of workpiece: 5000kg

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Specifications | Units | DVT5116D*1600

(Height) |

| Workbench diameter | mm | 1400 |

| Max.cutting diameter of vertical tool holder | mm | 1600 |

| Max.height of workpiece | mm | 1600 |

| Max.weight of workpiece | Kg | 5000 |

| Max.cutting force of vertical tool holder | N | 25000 |

| Max.torsional moment | N.m | 25000N.m |

| Workbench speed change | Steps | 16 |

| Workbench speed range | r/min | 5~160 |

| Feed level of vertical tool post | Step-less | |

| Feed range of vertical tool post | mm/min | 1~500 |

| Vertical tool post rapid movement speed | mm/min | 2000 |

| Cross-head travel | mm | 1250 |

| Crossbeam lifting speed | mm/ min | 440 |

| Vertical tool post travel – horizontal | mm | 915 |

| Vertical tool post travel – vertical | mm | 1000 |

| Tool holder size (width*height) | mm | 40*40 |

| Ram cross-section size | mm | 240*180 |

| main motor power | KW | 30 |

| Machine tool dimensions (length*width*height) | mm | 2660*2740*3528 |

| Machine weight | kg | 12700 |

| Specifications | Units | DVT5116D*1800

(Height) |

| Workbench diameter | mm | 1800 |

| Max.cutting diameter of vertical tool holder | mm | 2000 |

| Max.height of workpiece | mm | 1800 |

| Max.weight of workpiece | Kg | 8000 |

| Max.cutting force of vertical tool holder | N | 25000 |

| Max.torsional moment | N.m | 32000N.m |

| Workbench speed change | Steps | 16 |

| Workbench speed range | r/min | 3.2~100 |

| Feed level of vertical tool post | Step-less | |

| Feed range of vertical tool post | mm/min | 1~500 |

| Vertical tool post rapid movement speed | mm/min | 2000 |

| Cross-head travel | mm | 1450 |

| Crossbeam lifting speed | mm/ min | 440 |

| Vertical tool post travel – horizontal | mm | 1190 |

| Vertical tool post travel – vertical | mm | 1600 |

| Tool holder size (width*height) | mm | 40*40 |

| Ram cross-section size | mm | 240*180 |

| main motor power | KW | 37 |

| Machine tool dimensions (length*width*height) | mm | 3200*2800*3850 |

| Machine weight | kg | 17000 |

| Specifications | Units | DVT5116D*2000

(Height) |

| Workbench diameter | mm | 1800 |

| Max.cutting diameter of vertical tool holder | mm | 2000 |

| Max.height of workpiece | mm | 2000 |

| Max.weight of workpiece | Kg | 8000 |

| Max.cutting force of vertical tool holder | N | 25000 |

| Max.torsional moment | N.m | 32000N.m |

| Workbench speed change | Steps | 16 |

| Workbench speed range | r/min | 3.2~100 |

| Feed level of vertical tool post | Step-less | |

| Feed range of vertical tool post | mm/min | 1~500 |

| Vertical tool post rapid movement speed | mm/min | 2000 |

| Cross-head travel | mm | 1650 |

| Crossbeam lifting speed | mm/ min | 440 |

| Vertical tool post travel – horizontal | mm | 1190 |

| Vertical tool post travel – vertical | mm | 1600 |

| Tool holder size (width*height) | mm | 40*40 |

| Ram cross-section size | mm | 240*180 |

| main motor power | KW | 37 |

| Machine tool dimensions (length*width*height) | mm | 3200*2800*4050 |

| Machine weight | kg | 18000 |

Resources & Downloads:

DVT5116D Single-Column Vertical Lathe Product Introduction :

Product description

DVT5116D is a single-column vertical lathe with a Max.turning diameter of 1600mm and a Max.work-piece height of 1600mm. It is suitable for high-speed steel cutting tools and carbide cutting tools, processing various non-ferrous metals, ferrous metals and some non-metallic materials.

The machine tool can process internal and external cylindrical surfaces, flat surfaces, cutting, and grooving.

Features

1.Main transmission mechanism

This machine tool consists of a column, main gearbox, workbench, beam lifting mechanism, vertical tool rest, electrical system, hydraulic system, etc. The cross beam moves up and down on the column guide rail. There is a vertical tool holder on the cross beam, which can feed and move quickly in both horizontal and vertical directions. The main motion is driven by an AC motor, and the machine tool is equipped with a button station. All operations on the machine tool are concentrated on the button station.

2.Main transmission mechanism

The main drive of the machine tool is driven by an AC motor, and the hydraulic cylinder drives the shift fork for gear shifting, which allows the worktable to achieve a speed of 5~160r/min.

3.Feeding mechanism

The horizontal (X-axis) and vertical (Z-axis) feed directions of the vertical tool post are driven by AC servo motors, and the ball screw is driven by a planetary reducer, so that the vertical tool post moves in both directions of the X-axis and Z-axis. Get corresponding feeds and rapid movements.

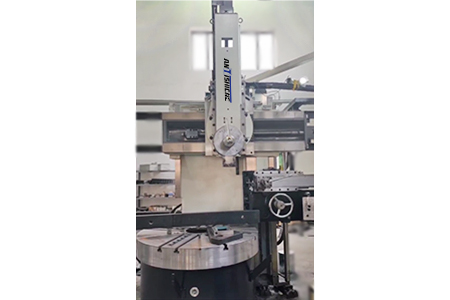

4.Worktable

The worktable adopts dynamic pressure guide rail, and its main shaft is equipped with two NN3000 double-row short cylindrical roller bearings. The inner ring has a taper to adjust the radial clearance. Both bearings have oil flow to lubricate and ensure the axial and radial accuracy of the workbench. There are four manual claws on the workbench.

5.Column

The column is connected to the base of the workbench and is made of high-strength, low-stress cast iron. There is a beam lifting mechanism on the upper end of the column. Driven by an AC motor, the beam can move up and down on the column.

6.Cross-beam

The crossbeam moves up and down on the column guide rail, and the crossbeam is lifted and lowered by a single screw. A safety floating nut device is installed on the crossbeam to ensure that the crossbeam works accurately, safely and reliably during the lifting and lowering process. The cross beam is amplified by a hydraulic cylinder through a lever on the column and pushes the inclined iron to clamp or loosen it. The clamping mechanism has the characteristics of simple structure and convenient maintenance and operation.

7.Vertical tool holder (square ram)

The vertical tool holder has a three-layer structure, consisting of a beam slide, a rotary slide and a ram. The crossbeam slide and rotary slide are made of high-strength, low-stress cast iron. The ram is made of ductile iron. The slide guide surface of the tool holder is precision scraped and ground with a soft guide rail tape. All ball screw support bearings use combined bearings. . Does not include side tool holder.

8.Hydraulic system

The hydraulic system is composed of the workbench dynamic pressure guide rail control system, the main transmission transmission system, the beam clamping and relaxing system, the main transmission lubrication, etc., and the main hydraulic components are all products from domestic high-end manufacturers to ensure the quality of the hydraulic components.

9.Centralized lubrication

The lubrication method mainly uses centralized lubrication stations for regular and quantitative centralized lubrication.

Standard Equipment:

| Name | Specifications | Quantity |

| Lathe Machine | DVT5116D | 1 Set |

| Iron Gasket | Comes with M24X500 anchor screws, nuts, flat washers | 16 Sets |

| Chuck Jaw | With positioning plate | 4 Sets |

| Left Knife Holder | For left knife holder | 1 Set |

| Right Knife Holder | For right knife holder | 1 Set |

| High Quality Work Light | Installed on the left and right sliding seats | 1 Set |

| Toolbox | There are common tools and special tools | 1 Set |

Main parts purchase list:

| NO. | Name | Supplier |

| 1 | Spindle Bearings | KTL |

| 2 | Electrical Components | SPARK 213 |

| 3 | Oil Pump | CHINA |

| 4 | Hydraulic Parts | CHINA |

| 5 | The Electromagnetic Valve | CHINA |

| 6 | Centralized Lubricator | CHINA |

| 7 | Ball Screw | CHINA |

| 8 | Screw Support Bearing | NSK/INA |

| 9 | Plastic Paste | CHINA |

| 10 | Digital Display | CHINA |

| 11 | Gearbox | ANTISHICNC |

| 12 | Main Motor | CHINA |

| 13 | Gear/Shaft | CHINA |

| 14 | Casting | CHINA |

| 15 | Reducer | NEWSTART |

Note: Due to factors such as the procurement cycle, the manufacturer reserves the right to replace purchased parts of the same quality and different brands, but imported purchased parts do not need to be replaced with domestic parts.

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life