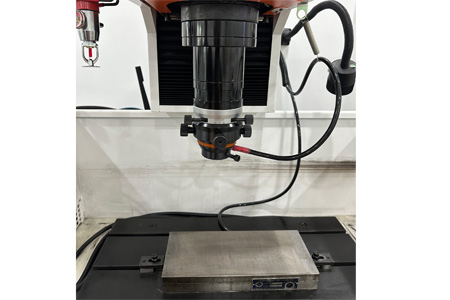

G45 CNC Mirror Discharge Die Sinker EDM Machine

X,Y,Z Axis travel

450*350*300mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Specifications | G45 CNC Mirror Discharge Die Sinker EDM Machine

(A3-50) |

| Machine tool | |

| machine tool structure | Workbench sports style |

| overall dimension | 2000*2430*2300mm |

| Machine weight | 2600kg |

| X axis/Y axis/Z axis | |

| Control accuracy of each axis | 0.0001mm |

| X,Y,Z Axis resolution | 0.01mm |

| X,Y,Z Axis travel | 450*350*300mm |

| Three axis positioning accuracy | 0.008mm(GB/T17421.1) |

| Three axis repeated positioning accuracy | 0.002mm(GB/T17421.1) |

| Working area | |

| Size of working fluid tank (length*width*depth) | 850*700*270mm |

| Workbench dimensions (length*width) | 700*400mm |

| Attachment installation board to workbench distance | (300-600)mm |

| lubricating system | Manual centralized lubrication |

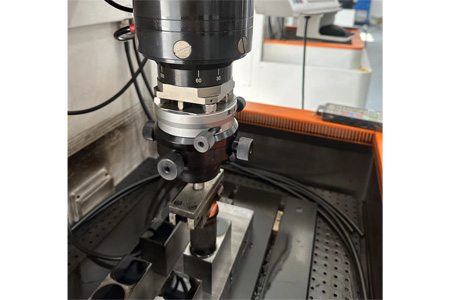

| Workpiece and electrode | |

| Maximum electrode weight | 50kg |

| Electrode installation | manual adjustment |

| maximum workpiece weight | 400kg |

| Working fluid system | |

| Filter | Paper core filtration |

| Pulse power supply | |

| Maximum processing current | 50A |

| Maximum processing efficiency | 500mm³/min |

| Optimal surface roughness | 0.07mm |

| Minimum electrode loss | 0.1% |

| Minimum current control | 0.1A |

| Communication mode | Ethercat BUS |

| Servo type | Ethercat BUS |

| Operating system | |

| operating system | LINUX |

| Data input | LCD display screen, mouse or touch screen, keyboard or manual control box |

| Driving method | Absolute AC servo drive |

| Interpolation function | Straight lines, arcs, ellipses, any curve according to software |

| Processing discharge conditions | unlimited |

| Input range | +9999.999~-9999.999 |

Resources & Downloads:

G45 CNC Mirror Discharge Die Sinker EDM Machine Product Introduction :

Equipment Introductions

ANTISHICNC”-G45″ is a fully automatic CNC electric discharge molding machine with a “C” structure and worktable movement. Each axis achieves high-precision machining in the “positive” and “negative” directions with a minimum control accuracy of “0.1 μ m”. The control accuracy is ten times that of ordinary CNC machine tools, truly achieving high-precision machining.

The system adopts advanced bus control and closed-loop control methods; After power failure, processing can continue from the current point without returning to the mechanical zero point of each axis; No mechanical limit switches are required for each axis, reducing the failure rate; The discharge circuit adopts a voltage stabilizing circuit, which is not affected by changes in external network voltage and does not affect the machining effect; Multiple materials electrode pairs processing database, realizing true human-machine dialogue operation, allowing you to obtain unimaginable processing results; Remote control, remote operation, and automation control are far ahead technologies that are easy to handle.

ANTISHICNC’s “A3B-50” CNC power supply with high stability and anti-interference ability can achieve extremely low electrode loss in electrical discharge machining, resulting in higher precision and longer service life of your mold processing.

Features

Mechanical Part

1. The whole machine casting is made of high-quality resin sand material, which has undergone multiple annealing stress treatments to ensure the best accuracy and durability, and will not deform after long-term use.

2. Each axis is driven directly by AC servo motors and precision ball screws.

3. Each ANTISHICNC machine tool undergoes strict inspection using a RENISHAW laser interferometer from the UK.

Power Supply(A3-50)

1. Adopting LINUX multi window, multitasking, and real-time kernel operating system. Embedded NC, with lower power consumption and higher reliability.

2. ETHERCAT bus communication, servo drive, and discharge acquisition methods provide faster response speed and more accurate data.

3. It has a power-off memory function and can continue processing without returning to the mechanical origin after power failure.

4. Adopting absolute value encoder control method, each axis does not require mechanical limit, reducing the failure rate of long-term use. Realize remote control and automated operation.

Powerful CNC shaking function: Numerical control shaking plays a crucial role in the entire machining process of CNC electric discharge machine tools. The system has powerful shaking function, high-speed shaking response, and with high-speed tool lifting, the machining indicators will be greatly improved.

Thinking swing: Processing deep cavities and repairing side walls

Free swing: Processing relatively shallow surfaces

Locked shaft swing: Processing screw threads or undercuts

Layered swing: Processing large and extra-large areas

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life