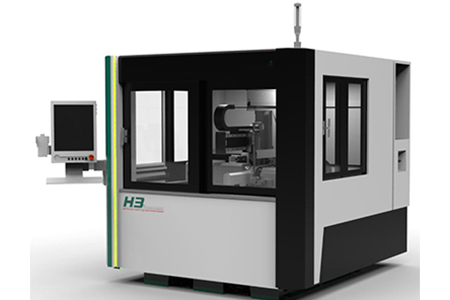

H3 High precision CNC step grinding machine fully automatic peripheral grinder

Clamping workpiece dia. : 0.5-20 mm

Grinding workpiece dia. : 0.05-20 mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| NO. | Technical Descriptions | Unit | Model: H3 | |

| 1 | Clamping work-piece diameter rang | mm | 0.5-20 | |

| 2 | Grinding work-piece diameter range | mm | 0.05-20 | |

| 3 | Clamping / grinding work-piece Maximum length | mm | 300/200 | |

| 4 | Control system (CNC-4 axis) | ANCA-X/Y/Z/Z′ | ||

| 5 | Feeding and receiving station system (CNC-3 axis) | ANCA-U/V/W | ||

| 6 | Rough grinding | Grinding wheel size (diameter) × width × Aperture) | mm | 250×20×31.75 |

| 7 | Grinding wheel speed | rpm | 0~8500(Motorized spindle) | |

| 8 | Maximum linear speed of grinding wheel | m/s | 90 | |

| 9 | Grinding wheel spindle motor | KW | 8.5/20 | |

| 10 | Fine grinding | Grinding wheel size (diameter) × width × Aperture) | mm | 150×20×31.75 |

| 11 | Grinding wheel speed (motorized spindle) | rpm | 0~12000(Motorized spindle) | |

| 12 | Grinding wheel maximum linear speed | m/s | 90 | |

| 13 | Grinding wheel spindle motor | KW | 5 | |

| 14 | X/Y/Z/Z′axis Minimum feed rate | mm | 0.001 | |

| 15 | X-axis stroke (rough grinding axle) | mm | 100 | |

| 16 | Y-axis stroke (fine grinding wheel axle) | mm | 29 | |

| 17 | Z-axis stroke (working head) | mm | 380 | |

| 18 | Z ‘axis stroke (fourth axis) | mm | 55 | |

| 19 | X/Y/Z/ Z′axis servo motor | KW | 2 | |

| 20 | Head spindle table motor | KW | 1 | |

| 21 | Working head Spindle speed | rpm | 0-2000 | |

| 22 | High pressure oil pump | KW | 0.25 | |

| 23 | Working head spindle rotation mode | fixed | ||

| 24 | Support length positioning mode | Front positioning | ||

| 25 | Manipulator U / V / W axis servo motor | KW | 1 | |

| 26 | Grinding fluid tank | mm | 300*300*1000 | |

| 27 | Gross weight (approx.) | Kg | 5000 | |

| 28 | Overall dimension (length) × wide × High) | mm | 2450*1980*2000 | |

H3 High precision CNC step grinding machine fully automatic peripheral grinder Product Introduction :

Product introduction :

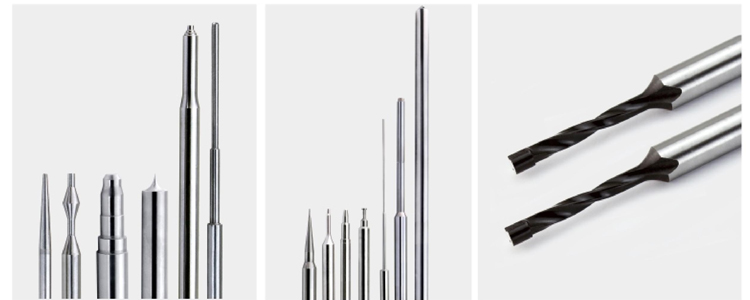

The walking center level difference grinder adopts a special walking center structure, which can grind multiple stages of work-pieces within 0.05-20 mm. It adopts the Chinese secondary development highly automated grinding system developed by Australian ANCA company, which can freely move and rearrange buttons and icons. The creation interface of multi-step and complex interrupted work-pieces can be realized without programming, and the interactive touch screen technology with high performance can easily realize more advanced gesture commands.

Standard Equipment

| No. | ITEM |

| 1 | CNC control system |

| 2 | X / Z axis feed servo motor |

| 3 | X / Z axis ball screw |

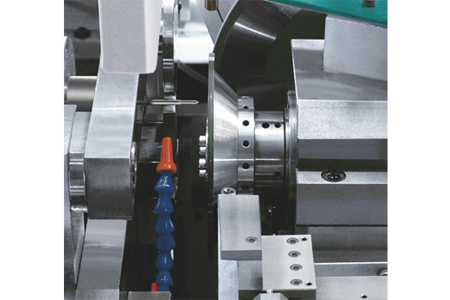

| 4 | Collet and clamping head |

| 5 | Rough grinding spindle |

| 6 | Fine grinding spindle |

| 7 | Manipulator servo |

| 8 | End face positioning device |

| 9 | Full automatic oiler |

| 10 | coupling |

| 11 | Wear resistant material |

| 12 | Water pump drive motor |

| 13 | Switch button / contact |

| 14 | Belt |

| 15 | Oil circuit components |

| 16 | Bearing |

| 17 | LED work light |

| 18 | Cooling water tank |

| 19 | Foundation cushion block |

Optional Equipment

| No. | ITEM |

| 1 | Scroll double effect filter (including cooling device) |

| 2 | Oil mist separator |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.