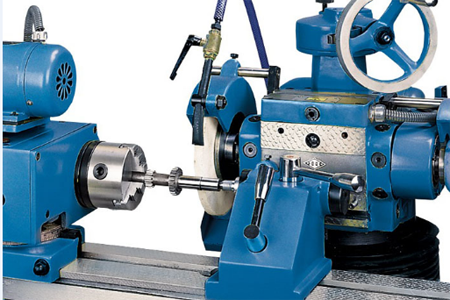

Multl-Use Grinding Machine 2M9120A

Grinding dia. : 200 mm

Workpiece length max. : 500 mm

Workpiece weight max. : 10 kg

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Working area | |

| Grinding diameter | 200 mm |

| Workpiece length (max.) | 500 mm |

| Workpiece weight (max.) | 10 kg |

| Workpiece width surface grinding | 50 mm |

| Workpiece length surface grinding | 200 mm |

| Grinding length | 200 mm |

| Inside grinding measures, optimal | Ø10-50 x 75 mm |

| Outside grinding measure, maximum | Ø5-50 x 400 mm |

| Tool grinding measure | 200×500 mm |

| Table swivel range (max.) | +45° / -30° |

| Travels | |

| Travel Z-axis | 480 mm |

| Feed | |

| Feed per hand-wheel rotation X-axis, fine | 1 mm |

| Feed per hand-wheel rotation X-axis, rough | 4 mm |

| Feed per scale division X-axis, fine | 0,005 mm |

| Feed per scale division, X-axis, rough | 0,02 mm |

| Scale division of height adjustment | 0,01 mm |

| Tailstock | |

| Height adjustment per handwheel rotation | 1 mm |

| Tailstock taper | MT 2 |

| Tailstock quill stroke | 14 mm |

| Grinding headstock | |

| Grinding spindle speed | 2500 rpm |

| Inside grinding spindle speed | 13500 rpm |

| Grinding headstock swivel range | ± 90 ° |

| Headstock | |

| Working headstock swivel range | ± 90 ° |

| Working spindle taper | MT 2 |

| Working spindle speed | (3) 110 – 300 rpm |

| Chuck diameter | 100 mm |

| Drive capacity | |

| Machine drive capacity | 2.525 kW |

| Motor rating main drive | 1.1 kW |

| Measures and weights | |

| Grinding wheels dimensions | 200x20x75 mm |

| Grindstone dimensions, inside grinding (min.) | 10x10x3 mm |

| Grindstone dimensions, inside grinding (max.) | 25x20x6 mm |

| Overall dimensions (length x width x height) | 1520x1350x1400 mm |

| Weight | 1300 kg |

Resources & Downloads:

Multl-Use Grinding Machine 2M9120A Product Introduction :

Grinding machine model 2M9120A is a kind of universal machine。It has both the characters of a universal cylindrical grinding machine and the characters of a tool and cutter grinding machine and is suitable for external grinding , internal grinding and surface grinding as well as for sharpening general cutting tools such as various milling cutters , reamers , pinion cutters and straight fluted hobs , etc. This machine is suitable for common small machine plants, tool workshops , repair workshops and research institutes of science and technology.

Features

1.The functionality of the Multi-Grind ranges from external and internal cylindrical grinding to taper grinding.

2.The Multi-Grind also allows easy tool grinding (sharpening of cutters, reamers and turning tools) and is suitable for light surface grinding job.

3.Three-Point Bearing The custom three-point bearing of the grinding spindle ensures minimum temperature effects and consistent grinding quality.

4.Feed Drives Hydraulic table feed (longitudinal) with automatic change of direction.

5.An additional manually operated longitudinal feed with hydraulic support allows feed speeds up to 7 m/min.

6.Grinding Headstock Special grinding headstock design allows simultaneous setup of 2 different grinding wheels.

7.The grinding headstock can be moved in transverse direction and also vertically; and it can be rotated around the vertical axis.

8.Speeds The headstock operates at 3 different speeds (110, 200, 300 min-1), which are set through an easy to operate gear shift lever.

9.central lubrication system – sturdy construction

10.minimizes vibration effects – electrical components are mounted easily accessible in a control cabinet

Standard Equipment

Coolant equipment

6 Piece-Grinding wheel

1 Set-Internal grinding wheel head

1 Piece-Extended grinding wheel spindle

1 Set-Cutter head

1 Set-Ttree-jaw chuck

1 Set-Plane grinding

1 Piece-Centre

1 Set-Tooth rest

1 Piece-Centre

1 Set-Lefttailstock

5 Set-Driving dogs

1 Set-Wheel dresser

3 Piece-Wheel pullers

2 Piece-Vee-belt

1 Set-Wheelbalancing stand

1 Piece-Flat belts

3 Sets-Flangesfor grinding wheel

2 Piece-Centering technical sleeves

2 Sets-Wheel guards

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life