IG150 High Precision CNC Internal Grinder

Grinding Dia. : 6-200 mm

Max. Depth : 150-200 mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Project | Unit | IG150 | IG150-I |

| Grinding inner dia. range | mm | Φ6-150 | Φ6-200 |

| Grinding hole for the longest depth | mm | 150(Integrated spinde max. grinding depth: 300mm) |

200 |

| Bench rotation dia. | mm | 520 | 520 |

| Rotation dia. inside the waterproof cover |

mm | 320 | 320 |

| Max. stroke of the workbench |

mm | 540 | 540 |

| Workpiece spindle rotation speed |

r.p.m. | 0~3000 | 0~3000 |

| Spindle table slide feed speed |

m/min | 8 | 8 |

| X-axis feed rate | m/min | 8 | 8 |

| X-axis min. moving unit | mm | 0.001 | 0.001 |

| Z-axis min. moving unit | mm | 0.001 | 0.001 |

| Spindle table rotation adjustment angle Feeding method |

Forward 15° backward2″ | Forward 15° backward2″ | |

| Feeding method | Servo motor | Servo motor | |

| Wheel motor | 2HP | 2 (Three-phase motor) | 2 (Three-phase motor) |

| X-axis servo motor | KW | 1.5(1 axis) | 1.5(1 axis) |

| Z-axis servo motor | KW | 2.0 | 2.0 |

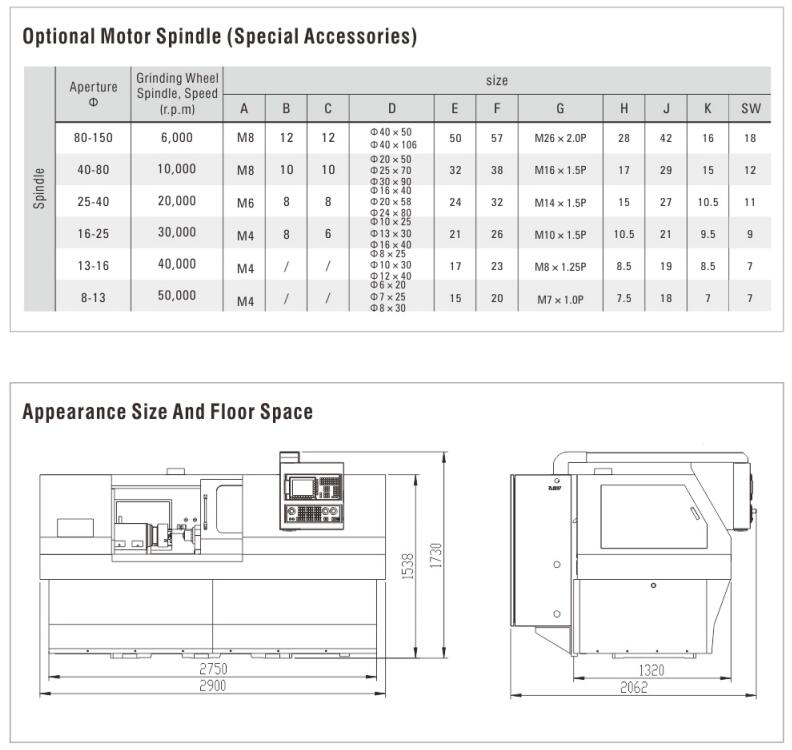

| Floor area | mm | 2500LX2100W | 2500LX2100W |

| weight (about) | KG | 3000 | 3200 |

Resources & Downloads:

IG150 High Precision CNC Internal Grinder Product Introduction :

Product Description :

● The body design is ergonomically designed for easy operation

● Compact internal grinding machine with small installation space and suitable for any workshop

● The sliding surface adopts static pressure automatic lubrication system, which has smooth movement and good wear resistance.

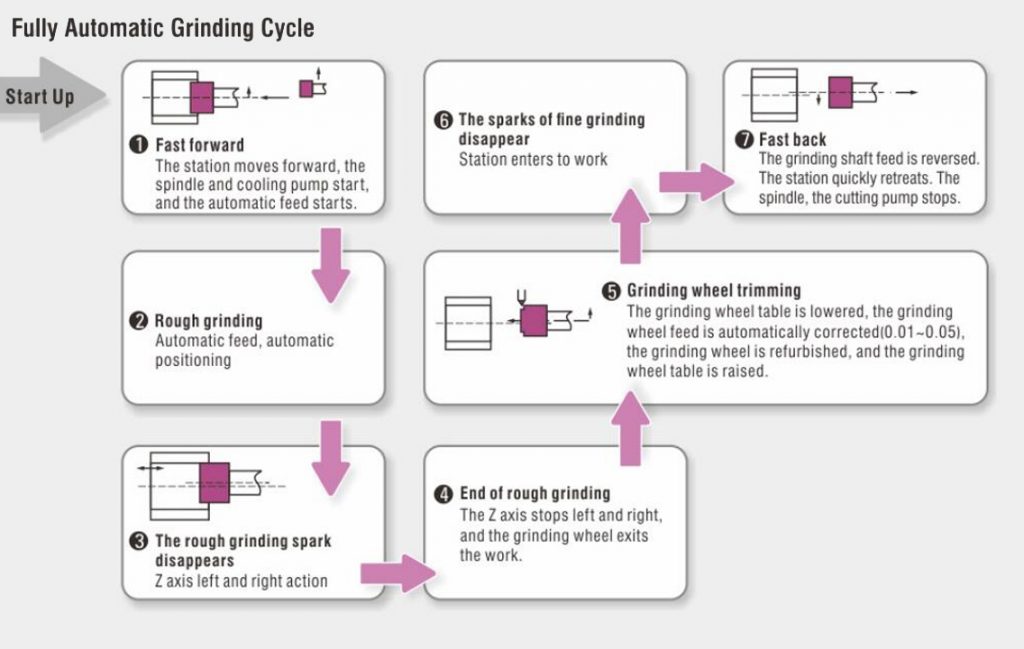

● Fully automatic grinding: rough grinding, dressing, fine grinding, non-sparking grinding cycle action. High precision, easy operation and greatly increased production capacity. Suitable for mass production and grinding of a small amount of different form workpieces.

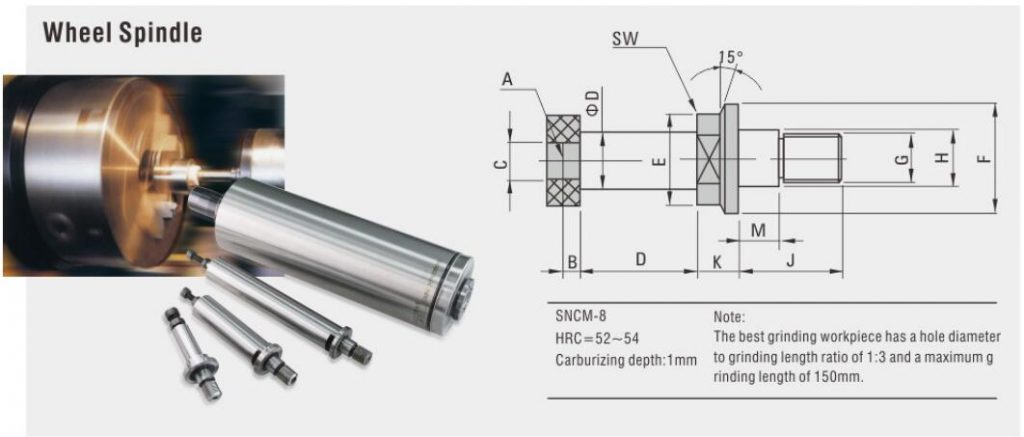

● The head frame rotates with P4 high-precision spindle bearings, featuring high precision, high rigidity and quiet operation.

● The feed shaft is equipped with a precision ball screw, which is driven by a servo motor and can be fed without a section.

● Dressing mode is CNC automatic correction and dressing

(1) If you use diamond or CBN grinding wheel, you can choose not to correct the dressing mode.

(2) For workpieces that are difficult to grind, multiple correction modes can be selected to ensure the best processing quality.

● In mass production, automatic production equipment such as automatic feeding and automatic unloading can be installed.

Standard Equipment

1. Grinding cooling device (water tank/ water

pump/ water pipe)(1 set)

2. Diamond trimming pen (1 pcs)

3. Angle adjustment table (1 pcs)

4. Toolbox (hex wrench set/ Open end wrench/

screwdriver) (1 pcs)

5. Spindle grinding wheel post (3 pcs)

6. High-speed grinding spindle (RMP optional) (1 pcs)

7. Basic adjustment block (6 pcs)

Optional Equipment

1. Hydraulic three-jaw chuck

2. Chuck flange

3. Mechanical spindle: 10,000/20,000/30,000rpm

Electric spindle: 40,000/100,000rpm

4. End face detecting device

5. Magnet filter

6. Paper tape filter

7. Closed full cover and automatic door

8. Inner diameter automatic measuring device

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life