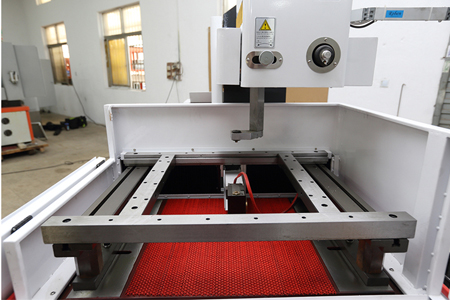

DK Series C-frame structure middle cutting speed economic type WEDM wire cutting machine

Work table size :

400*670 mm

490*800 mm

700*1000 mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Model | DK7732C | DK7740C | DK7750C |

| Bed casting | Precision casting, high temperature annealing, constant mechanical accuracy | ||

| Workbench design | Full support design, wide spacing between XY axis support rails, good stability and strong bearing capacity | ||

| Control System | HF/CAD | HF/CAD | HF/CAD |

| Machine tool guide | Linear Guides | Linear Guides | Linear Guides |

| Work table size | 400*670 mm | 490*800 mm | 700*1000 mm |

| X-axis travel (mm) | 320 | 400 | 500 |

| Y-axis travel (mm) | 400 | 550 | 630 |

| Z-axis travel (mm) | 230 | 280 | 320 |

| UV axis travel (mm) | 30*30 | 30*30 | 30*30 |

| Standard cutting slope | ±6°/80mm | ±6°/80mm | ±6°/80mm |

| Molybdenum wire diameter | 0.18 mm | 0.18mm | 0.18mm |

| Multi-cutting accuracy (mm) | ≤±0.005(10mm*10mm round) | ≤±0.005(10mm*10mm round) | ≤±0.005(10mm*10mm round) |

| Positioning accuracy (mm) | ≤±0.003/300 | ≤±0.003/300 | ≤±0.003/300 |

| Repeat positioning accuracy (mm) | ≤±0.003 | ≤±0.003 | ≤±0.003 |

| Best Surface Roughness (mm) | Ra≤1.0( SKD11 or Cr12,HRC58 ) | Ra≤1.0( SKD11 or Cr12,HRC58 ) | Ra≤1.0( SKD11 or Cr12,HRC58 ) |

| Bed size (L*W*H) | 1470*800*1830mm | 1750*1000*1880mm | 1750*1000*1880mm |

| Control cabinet size (L*W*H) | 660*600*1650mm | 660*600*1650mm | 660*600*1650mm |

| Tank size (L*W*H) | 900*620*480mm | 900*620*480mm | 900*620*480mm |

| Working fluid capacity | 60L | 60L | 60L |

| Machine Overall weight | 1500kg | 2100kg | 2100kg |

| X, Y axis verticality | ≤±0.001(320*400) | ≤±0.001(400*550) | ≤±0.001(400*550) |

| Maximum work weight | 400kg | 600kg | 1000kg |

| Working fluid | Water-based cutting fluid | Water-based cutting fluid | Water-based cutting fluid |

| Machine tool power consumption | 2.0kw | 2.0kw | 2.0kw |

Resources & Downloads:

DK Series C-frame structure middle cutting speed economic type WEDM wire cutting machine Product Introduction :

Product Details

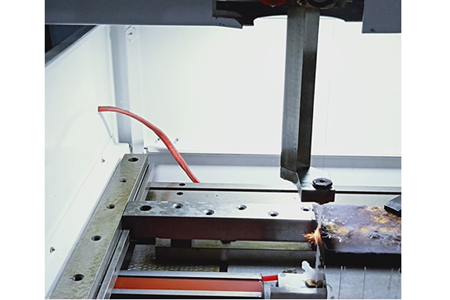

In the wire cutting, the continuous moving molybdenum wire (called electrode wire) is used as the electrode, and the workpiece is subjected to pulse spark discharge to remove metal and cut into shape. The quality of the processed workpiece is between the fast wire and the slow wire, so it is called the medium wire. To be precise: the medium wire is an upgraded product of the fast wire. It can be understood as: the fast wire that can be cut many times, but it is The cutting speed is not slower than that of fast wire feeding, but higher than that of fast wire feeding. Only in the process of multiple cutting, the cutting speed can be reduced to achieve the cutting effect. At this time, the average efficiency is calculated, not the highest efficiency, and the processing The quality also tends to walk slowly. The wire running speed is automatically controlled by the system and can be adjusted as needed.

The wire cutting machine tool has multiple cutting functions. During processing, the control system will automatically adjust the processing parameters (high-frequency pulse width, pulse interval, number of power tubes and wire cutting speed) according to the programming process, and it will also be processed at the same time. The processing parameters can be changed manually and adjusted appropriately.

The medium-travel wire cutting machine has the processing method of walking three and retreating two. This processing method is the processing method used by most of the medium-traveling wires on the market. The principle of this processing method is to automatically reverse the direction of the wire, and travel in the opposite direction after three seconds. Two seconds to ensure that the molybdenum wire gradually moves forward.

The medium wire cutting machine has the processing method of unilateral electric discharge. The unilateral electric discharge machining process is: the molybdenum wire is discharged in one direction, and it is not discharged after the reverse direction. This processing method is better than the parts processed by three steps and two steps. , because it only discharges in one direction and will not cause traces of molybdenum wire.

The wire feeder is mainly used to process various complex and precise small workpieces, such as the punch and die of the mold. It is developed on the basis of EDM perforation and forming. It has not only developed the application of EDM, but also replaced EDM perforation and forming in some aspects. Wire cutting machine tools have accounted for more than half of EDM machines.

Features

1. The host adopts high-quality HT250 resin sand and has been tempered many times to eliminate internal stress and keep the machine tool accuracy unchanged for a long time.

2. Bidirectional constant tension wire structure, long-term processing without manual wire tightening, so that the precision and surface quality of the processed workpiece are strongly guaranteed.

The wire barrel motion bearing adopts all imported precision bearings, which has a longer service life. The guide wheel adopts a special high-precision guide wheel and adopts all imported bearings, which greatly increases the service life.

3. It adopts slow-moving water tank filter device, special water-based cutting fluid and multi-layer filter system. The self-priming pump has better performance and longer service life, which lays the foundation for the high precision and roughness of the processing surface.

4. One-stop automatic centralized oil supply device can make X, Y guide rails, screw rods, screw cylinder guide rails and screw rods all lubricated to ensure the service life of the machine tool.

5. Industrial PC machines are used to form an integrated programming control system for medium wire cutting. Combined with the process database, the system can provide the best processing conditions to achieve high-speed processing, quality assurance, and simplified operation. The system is a complete wire cutting solution. AutoCut system consists of AutoCut system software, motion control card based on PCI bus, high reliability, servo drive control main board, AC high frequency discharge board and sampling circuit. AutoCut system software includes AutoCAD wire cutting module, NCCAD (including wire cutting module), AutoCut plug-in of CAXA and machine tool control software.

6. In order to ensure the accuracy of each intermediate wire-feeding machine, the British Renishaw laser interferometer is used to check the positioning accuracy and repeatability of the equipment. The wire conveying system adopts a high configuration guide wheel and wire nozzle, and the reasonable layout completely solves the phenomenon of unilateral loose wire, so that the machined surface can achieve uniform roughness.

Standard Equipment

Precision Ball Guide

Table ball screw (material GCr15)

Capstan

Table ball screw bearing D246205/P5 (pair supply)

Wire bearing D246202/P5, guide wheel bearing D24/P5

Inverter

AC contactor 3TB4044-9A110V

Intermediate relay 3TH8262 110V 50HZ

Optional Equipment

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life