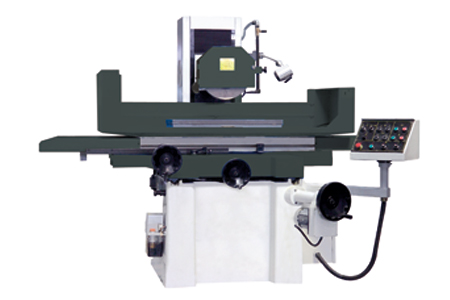

SGA Automatic Saddle Moving surface grinder

Max grinding size

460*200*350mm

813*406*400mm

1020*305*400mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Description | Unit | SGA2050AHD/SGA2050AHR | SGA2550AHD/SGA2550AHR | SGA3063AHD/SGA3063AHR | SGA30100AHD/SGA30100AHR | SGA4080AHD/SGA4080AHR | SGA40100AHD/SGA40100AHR |

| Table size(L*W) | mm | 460*200 | 500*250 | 635*305 | 1020*305 | 813*406 | 1020*406 |

| Max.grinding size of workpiece(L*W) | mm | 460*200*350 | 508*254*350 | 635*305*400 | 1020*305*400 | 813*406*400 | 1020*406*400 |

| T-slot of table(No.*width) | mm | 1*14 | 1*14 | 3*14 | 3*14 | 3*14 | 3*14 |

| Distance from spindle center to worktable | mm | 450 | 450 | 580 | 580 | 580 | 580 |

| Max. loading of table(including magentic chuck) | kg | 120 | 180 | 270 | 270 | 500 | 600 |

| Magnetic chuck size | mm | 460*200 | 500*250 | 300*600 | 300*1000 | 400*800 | 400*1000 |

| Wheel size(OD*Width*ID) | mm | 200*13* 31.75 | 200*13* 31.75 | 350*40*127 | 350*40*127 | 350*40*127 | 350*40*127 |

| Spindle speed(stepless) | r/min | 2850 | 2850 | 1450 | 1450 | 1450 | 1450 |

| Worktable speed | m/min | 7~23 | 7~23 | 7~23 | 7~23 | 7~23 | 7~23 |

| Vertical feed handwheel per revolution | mm | 1.25 | 2 | 1 | 1 | 1 | 1 |

| Vertical feed handwheel per division | mm | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 |

| Vertical auto feed | mm/stoke | 0.005/0.01/0.02/0.03/0.04/0.05 | 0.005/0.01/0.02/0.03/0.04/0.05 | 0.005/0.01/0.02/0.03/0.04/0.05 | 0.005/0.01/0.02/0.03/0.04/0.05 | 0.005/0.01/0.02/0.03/0.04/0.05 | 0.005/0.01/0.02/0.03/0.04/0.05 |

| Vertical feed rapid speed (motor) | mm/min | 460 | 460 | 460 | 460 | 460 | 460 |

| Transverse feed handwheel per revolution | mm | 5 | 4 | 5 | 5 | 5 | 5 |

| Transverse feed handwheel per division | mm | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| Transverse auto feed | mm/min | 0.1-8 | 0.1-8 | 0.1-8 | 0.1-8 | 0.1-8 | 0.1-8 |

| Transverse rapid feed | mm/min | 990 | 990 | 990 | 990 | 990 | 990 |

| Spindle motor | KW | 1.5 | 1.5 | 5.5 | 5.5 | 5.5 | 5.5 |

| Hydraulic motor | KW | 0.75 | 0.75 | 2.2 | 2.2 | 2.2 | 2.2 |

| Cooltant motor | KW | 0.04 | 0.04 | 0.125 | 0.125 | 0.125 | 0.125 |

| Elevating servo motor | KW | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Transverse feed motor | KW | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 |

| Total rated power | KW | 3.3 | 3.7 | 9 | 9 | 9 | 9 |

| Surface roughness | μm | Ra0.63 | Ra0.63 | Ra0.63 | Ra0.63 | Ra0.63 | Ra0.63 |

| Gross weight | kg | 1000 | 1500 | 2600 | 3300 | 3400 | 4000 |

| Package dimension(L*W*H) | mm | 1900*1720*2175 | 2000*2100*2175 | 2350*2220*2150 | 2950*2220*2210 | 2850*2270*2180 | 2950*2270*2180 |

Remark: AHR Model has no vertical move auto feed by servo motor function ,PLC controller realizing auto feed is only for AHD model.

Resources & Downloads:

SGA Automatic Saddle Moving surface grinder Product Introduction :

Product Features

High strength cast iron foundation

Machine longitudinal moves hydraulically or manually;

Transverse moves manually or frequency motor drives;

Vertical moves by servo motor,PLC controller realizing auto feed

Column adopts steel guide rail to improve rigidity

Grinding head adopts high precision rolling bearing spindle set, sleeve mounted, which can achieve high precision and high finish grinding

Application

This machine can grind steel, cast iron, non-ferrous metal and other materials, suitable for machining shop maintenance shop and tool shop use; The machine tool mainly uses the circumference of the grinding wheel to grind the work-piece or uses the end face of the grinding wheel to grind the work-piece vertically.

Standard Accessories

Coolant system, Hydraulic station,Lubrication system, Working light, Leveling wedges,Foundation screw, Wheel flange, Wheel balance arbor, tool and tool box, Magnetic chuck, Standard wheel, PLC controller and touched screen ,Operation manual.

Optional Accessories

Dust collection device

Paper filter

Magnetic separator

Wheel balance stand

Y /Z- axis DRO

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life