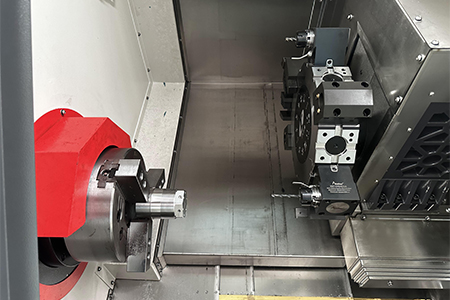

TCK50AY-800 CNC Turning and Milling Machine

Max swing dia. over bed:Φ640mm

Max swing dia. over slide:Φ380mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Item | Unit | TCK50AY-800 | |

| Max swing dia. over bed | mm | Φ640 | |

| Max swing dia. over slide | mm | Φ380 | |

| Center distance | mm | 800 | |

| Max disc processing diameter | mm | Φ450(When adjacent tools do not interfere) | |

| Max turning length | mm | 700 | |

| Spindle end type | – | A2-8 | |

| Spindle through hole diameter | mm | Φ86 | |

| Bar diameter | mm | Φ75 | |

| Hydraulic chuck | mm | 10 inch | |

| Hydraulic chuck tie rod through hole | mm | Φ75 | |

| Guide type | – | Linear guideway | |

| Spindle taper | – | Metric 92 1:20 | |

| Spindle speed | rpm | 3000rpm | |

| Tail-stock sleeve diameter | mm | 90 | |

| Tail-stock sleeve inner hole taper | No | MT5 | |

| Tail-stock sleeve stroke | mm | 80 | |

| Tail-stock type | – | Hydraulic (programmed) | |

| Tail-stock stroke | mm | 700 | |

| Power turret | set | 12 | |

| Tool holder model | BMT45 | ||

| Y-axis stroke | mm | ±45 | |

| Power turret chuck | mm | (ER25) | |

| Tool holder size | mm | 25´25 | |

| Max boring tool diameter | mm | Æ32 | |

| Screw model | X direction | 3210 | |

| Z direction | 4010 | ||

| Guide model | X direction | RGH45CA2R725 | |

| Z direction | RGH45CA2R1515 | ||

| X/Z motor torque | N.M | 15/15 | |

| X/Z fast moving speed | m/min | 18/18 | |

| X stroke | mm | 260 | |

| Z stroke | mm | 800 | |

| Min setting unit | mm | 0.001 | |

| Main motor power | KW | 15 | |

| Total power | KW | 32 | |

| Machine tool net weight | Kg | 4000 | |

| Overall dimensions (length × width × height) | mm | 3300*2000*2100 | |

Resources & Downloads:

TCK50AY-800 CNC Turning and Milling Machine Product Introduction :

Equipment Introductions

1.TCK50AY-800 is CNC turning and milling machine tools ; The whole machine has a compact structure, beautiful appearance, large spindle torque, high rigidity, stable and reliable performance, and excellent accuracy retention.

2.Adopting a 30° overall inclined bed structure and equipped with high-precision preloaded Taiwan linear roller guides, the machine tool has high position accuracy, smooth chip removal, and is suitable for high-speed and high-precision machining.

3.The spindle adopts a high-precision spindle bearing set and has been precision assembled and dynamically balanced tested to ensure high spindle accuracy, low noise and strong rigidity.

4.Using the tool turret method, the tool changing speed is fast and the positioning accuracy is high.

5.The X and Z direction feeds use servo motors directly connected to the screw through high-torque and low-inertia elastic couplings to ensure positioning accuracy and repeatable positioning accuracy.

6.Adopt advanced centralized automatic lubrication device, regular and quantitative automatic intermittent lubrication, and work stably and reliably.

7.Use domestic hydraulic chuck.

8.The hydraulic tail-stock is manually adjusted and locked, and the hydraulic piston is pressed against the work-piece for processing.

| Name | Model | QTY | Brand | Origin | |

| Control system | GSK988T | 1 set | GSK | Domestic | |

| Spindle motor | ZJY265A-15BM-B35 | 1 set | GSK | Domestic | |

| Spindle unit | CK230A2-8 (Brake disc) | 1 set | Haina | Domestic | |

| Spindle bearing | NN3024K+7024AC/DB+ NN3022K | 1 set each | Domestic | ||

| Guide rail | X direction | RGH45CA2R725 | 1 set | HIWIN/PMI | Taiwan |

| Z direction | RGH45CA2R1515 | 1 set each | HIWIN/PMI | Taiwan | |

| Ball screw | X direction | 3210/703 | 1 set | HIWIN/PMI | Taiwan |

| Z direction | 4010/1429 | 1 set each | HIWIN/PMI | Taiwan | |

| Screw bearing | 25TAC62/30TAC62 | 2 sets each | NSK | Japan | |

| Power turret | TCSDY80H-12T-330

(Synchronous belt) |

1 set | TCSM | Taiwan | |

| Power tool holder | 0 degrees (optional) | 1 set | TCSM | Taiwan | |

| Power tool holder | 90 degrees (optional) | 1 set | TCSM | Taiwan | |

| Automatic lubrication device | RBCLB-3ZK | 1 set | Hejin | Domestic | |

| Cooling pump | 370W | 1 set | Jianyang | Domestic | |

| Hydraulic station | 2.2kw | 1 set | MONFR | Domestic | |

| Hydraulic chuck | KT0-3/A2-8 | 1 set | BEEDF | Domestic | |

| Chip conveyor | Chain plate type | 1 set | Taihai | Domestic | |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life