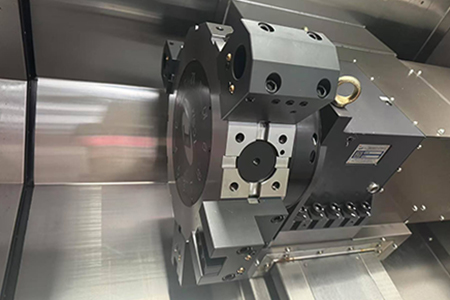

TCK63E Slant Bed CNC Lathe

Max. Swing over Bed:Φ650mm

Max. Swing over slide:Φ470mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Specifications | Unit | TCK63E |

| Max. Swing over Bed | mm | Φ650 |

| Max. Swing over slide | mm | Φ470 |

| Center distance | mm | 1320 |

| Max.processing diameter of plate type work piece | φ630 | |

| Max. turning length | mm | 1000 |

| Spindle end type | mm | A2-11 |

| Spindle through hole diameter | mm | Φ105 |

| Bar diameter | mm | Φ103 |

| Hydraulic chuck | mm | 15’’ |

| Hollow chuck pull rod through hole | mm | Φ90 |

| Guide way type | mm | Hard guide |

| Spindle Taper Hole Taper | No | Metric 110# |

| Spindle speed | rpm | 1-gear 30-150rpm;

2-gear: 100-450rpm; 3-3-gear 400-1500rpm |

| Gearbox transmission ratio | 1:1;1:4;1:11 | |

| Tailstock sleeve diameter | mm | 100 |

| Tailstock sleeve bore taper | No | MT5# |

| Tailstock sleeve travel | mm | 120 |

| Tailstock configuration | Hydraulic | |

| Tool turret | PC | 12 |

| Knife square size | mm | 32X32/Φ40 |

| Screw model | X direction | 4005 |

| Z direction | 5010 | |

| X/Z rapid traverse speed | m/min | 10/10 |

| X travel | mm | 325 |

| Z travel | mm | 1100 |

| Min. setting unit | mm | 0.001 |

| Main motor power | KW | 18.5 |

| Total power | KW | 22 |

| Machine net weight | Kg | 8000 |

| Dimensions (L×W×H) | mm | 3670 (4700 with chip removal machine) *1900*2300 |

Resources & Downloads:

TCK63E Slant Bed CNC Lathe Product Introduction :

Equipment Introductions

This series of machine tools is our company’s main export mature products, the whole machine structure is compact, beautiful appearance, spindle large torque, high rigidity, stable and reliable performance, with excellent accuracy retention.

45° overall heavy duty inclined bed structure, the use of high-precision hard rail configuration, minimize the center of gravity of the machine tool, the position of the machine tool is high precision, good rigidity, smooth chip removal, suitable for high rigidity and high precision processing.

Headboard optimization design, the use of external three-speed automatic gearbox, cutting torque, strong rigidity, suitable for disk, shaft parts turning processing, can be linear, circular arc, male inch thread, multi-thread processing, can be suitable for turning complex shape and high precision disk, shaft parts processing. Especially in the oil pipeline, coal, mining machinery and other industries have been recognized by the majority of users.

Choose the tool tower mode, the tool change speed is fast, the positioning accuracy is high. Commonly used for servo tool tower, can also choose power tool tower.

Wedge through hole chuck, fast clamping and loosening the work-piece under hydraulic action, fast clamping speed and high precision.

The screw and nut are processed, ground, assembled and quality controlled in the constant temperature workshop to ensure their high precision stability.

The hydraulic tail-stock is processed by means of hydraulic piston jacking up the work-piece.

RBCLB-3ZK positive displacement lubrication pump, automatic lubrication, mainly the bed guide rail and the dovetail surface of the drag plate, the lubrication surface between the ball screw and the nut continuous oil supply.

Standard Equipment

| Name | Specifications | Quantity | Supplier |

| Control System | GSK 988TA | 1 set | GSK |

| Spindle motor | 18.5 KW Servo | 1 set | GSK |

| Ball screw | X direction: 4005

Z direction: 5010 |

1 set | HIWIN/PMI |

| Tool holder | TCS-125-12T-440 | 1 set | Taiwan,China |

| Automatic lubrication device | RBCLB-3ZK | 1 set | China |

| Cooling pump | 380W | 1 set | China |

| Hydraulic station | 1.5kw | 1 set | China |

| Hydraulic chuck | KT15-3(solid center) | 1 set | China |

| hydraulic cylinder | RK200(solid center) | 1 set | China |

| Chip removal machine | Chain-plate | 1 set | China |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life