VTL-50A/VTL-55L/VTL-70L CNC Vertical Turret Lathe

Swing over bed : 800 mm

Max. turning dia. : 700mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Name | CNC Vertical Lathe | CNC Vertical Lathe | CNC Vertical Lathe |

| Model | VTL-55L | VTL-70L | VTL-50A |

| System | GSK 980TC3 | GSK 980TC3 | GSK 980TC3 |

| Travel | |||

| X axis | 330mm | 380mm | 300mm |

| Z axis | 650mm | 700mm | 500mm |

| Capacity | |||

| Max. Swing over bed | Φ630mm | Φ800mm | Φ650mm |

| Max. turning diameter | Φ550mm | Φ700mm | Φ500mm |

| Spindle | |||

| Spindle speeds | 50-1500rpm | 50-1500rpm | 50-2000rpm |

| Spindle motor power | 18.5KW | 22KW | 15KW |

| Spindle head type | A2-8 | A2-11 | A2-8 |

| Spindle bearing | NSK | NSK | NSK |

| Spindle hardness | HRC58-62 | HRC58-62 | HRC58-62 |

| Reduction ratio | 1:02 | 1:02 | 1:02 |

| Chuck & Automatic Tool Changer | |||

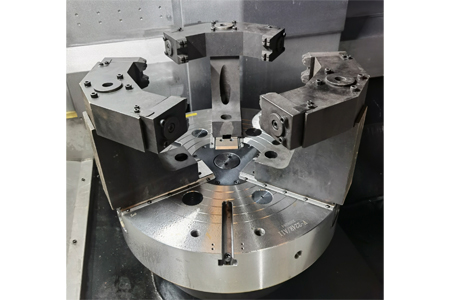

| Tool holder | Horizontal eight-station turret | Horizontal eight-station turret | Horizontal eight-station turret |

| Chuck | Φ500 | Φ500 | 12″ |

| Slide Way | |||

| X-axis rolling linear guide | 3 roots | 3 roots | 3 roots |

| Z-axis rolling linear guide | 2 roots | 2 roots | 2 roots |

| Ball Screw | |||

| Ball screw accuracy | Class C3 | Class C3 | Class C3 |

| Ball screw diameter | X、Z:φ50*10 | X、Z:φ50*10 | X、Z:φ40*10 |

| Screw bearing | HIWIN | NSK | NSK |

| Control System | |||

| X axis motor | 18NM | 18NM | 15NM |

| Z axis motor | 18NM | 22NM | 18NM |

| Feed Rate | |||

| X Z axis rapid feed rate | 16m/min | 16m/min | 16m/min |

| Accuracy | |||

| Repeat positioning | X. 0.004/Z. 0.005mm | X. 0.006/Z. 0.008mm | 0.008mm |

| Positioning | 0.008mm | 0.01mm | 0.01mm |

| Axial runout of spindle end | 0.005mm | 0.005mm | 0.008mm |

| Spindle centering shaft radial runout | 0.005mm | 0.005mm | 0.008mm |

| Cutting feed rate | 0.1-1000mm/min | 0.1-1000mm/min | 0.1-1000mm/min |

| Least input increment | 0.001mm | 0.001mm | 0.001mm |

| Power Require | |||

| Power source | 3¢-AC 380V 50Hz±5% | 3¢-AC 380V 50Hz±5% | 3¢-AC 380V 50Hz±5% |

| Others | |||

| Hydraulic pressure stands | Main accessories Taiwan | Main accessories Taiwan | Main accessories Taiwan |

| Cross weight | 7.5T | 8.5T | 5.5T |

Resources & Downloads:

VTL-50A/VTL-55L/VTL-70L CNC Vertical Turret Lathe Product Introduction :

Product Details

1.This machine tool is designed and manufactured with high-grade cast iron and box-shaped structure. After proper annealing treatment, the internal stress is eliminated, and the material is tough. In addition, the box-shaped structure design and high rigid body structure make the machine have sufficient rigidity and strength. , The whole machine shows the characteristics of heavy-duty cutting ability and high reproduction accuracy.

2.The base and the head stock are integrated box-type structure, with thick rib wall and multi-layer rib wall design, which can effectively suppress thermal deformation, and can withstand static and dynamic distortion and deformation stress, ensuring high rigidity and high stability of the bed.

3.The column adopts a unique wall plate + moving column structure, plus the X-direction three guide rail design, which provides powerful cutting ability and ensures the stability of the machine tool in the cutting state.

4.Servo spindle motor: high-precision, high-rigidity spindle head, this machine adopts high-horsepower spindle servo motor. Spindle bearing: NSK NN series bearings are selected. This bearing provides super strong axial and radial loads, which can ensure long-term heavy cutting. It has excellent precision, stability, low friction, good heat dissipation and spindle support rigidity.

5.X/Z servo motor: AC servo motor and large-diameter ball screw (accuracy C3 grade, pre stretching method, can eliminate thermal expansion and improve rigidity) direct drive, no cumulative error of belt drive, accurate repetition and positioning accuracy, The supporting bearing adopts high-precision angular ball bearing.

6.X/Z linear rails: The ultra-heavy-loaded linear rails with high rigidity and low friction coefficient of Taiwan HIWIN are used, which can realize high-speed feed, reduce the wear of rails, and prolong the accuracy of machine tools. This kind of linear slide way has a small friction coefficient and high quick response, which can show high machining accuracy requirements and can also realize high-load cutting.

7.Turret: imported horizontal eight-station, its power source uses hydraulic servo motor, which is fast and without wear, and its positioning adopts Japanese-made toothed positioning disc, its positioning precision is 5, and its repeatability is 3. In addition, the toothed positioning disc The high rigidity enables the work piece to obtain stable machining accuracy.

8.Electrical box: The electrical box is equipped with a heat ex-changer to ensure the stability of the system. The external wiring part has a protective coil, which is heat-resistant, oil-resistant and water-resistant.

9.Lubrication system: The machine’s automatic decompression lubrication system collects the oil supply in the middle, and uses the advanced decompression intermittent oil supply system to provide timely and appropriate oil supply to each lubrication point in timed, quantitative, constant pressure and separate ways to ensure Each lubricating position does get lubricating oil, so that the machine can operate for a long time without worries.

10.Fully dense sheet metal: Under the current strong requirements for environmental protection and operator safety, the design of sheet metal focuses on beautiful appearance, environmental protection and ergonomics. The fully sealed sheet metal design completely prevents the cutting fluid and chips from splashing outside the machine tool, so that the surrounding of the machine tool can be kept clean. In addition, both sides of the machine tool are designed to flush the bottom bed with cutting fluid, so that the chips will not stay on the bottom bed as much as possible, and the operator does not need to remove the chips.

Standard Equipment

CNC system

Spindle bearing

Server driver

Servo spindle motor

X/Z Servo Motor

Guide

Lead screw

Tool holder

Working lamp

Electrical device

Chip removal

Fully enclosed protective cover

Optional Equipment

CNC System: Siemens/FANUC etc.

Turret

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life