X6325 X6325C X6325D Universal Turret Milling Machine

Table size

254mm x 1270mm (10"x 50")

254mm x 1370mm (10"x 54")

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Item /Model | Unit | X6325 | X6325C | X6325D | |

| Table size | mm/” | 254×1270(10”x50”) 254×1370(10”x54”) | |||

| Long travel | mm | 840 940 | |||

| Cross travel | mm | 400 | |||

| Vertical travel | mm | 400 | |||

| T-slot No.and size | mm | 3×16 | |||

| Ram Travel | mm | 470 | |||

| Distance from spindle nose to table surface | mm | 0~400 | |||

| Spindle hole taper | – | Standard :R8 Optional :ISO 30/ISO40 | Standard: ISO40 | ||

| Spindle travel | mm | 127 | |||

| Spindle Speed | rpm | Standard: Shiftgrade 50HZ:66-4540 60HZ :80-5440 | |||

| rpm | Optional :

variable 60-4200 |

Optional :

variable 60-3600 |

|||

| Auto.quill feed | mm | Three steps:

0.04(0.0015”)/0.08(0.003”)/0.15(0.006”)mm/revolution |

|||

| Spindle motor | KW/HP | 2.25KW/3HP | 3.75KW/5HP | ||

| Head swivel | ° | 90° | |||

| Head tilting | ° | 45° | Fixed | 45° | |

| Dimension

of package |

One miller per case | mm | 1516x1550x2080 | ||

| Two miller per case | mm | 1650x1790x2170 | |||

| Three miller per case | mm | 1650x2285x2235 | |||

| G.W/set | KG | 1200 | 1490 | ||

Resources & Downloads:

X6325 X6325C X6325D Universal Turret Milling Machine Product Introduction :

Turret Milling Machine is also called Rocker arm universal milling machine

Product Feature:

1.Our milling machines has passed the strict CE certification and had already got the CE certificate. Our factory also get the ISO certificate.

2.Our universal turret milling machine are widely used for processing flat face, slope face, keyway, key groove, slot and drilling, reaming, boring in almost every country all over the world because of the high quality with competitive price.

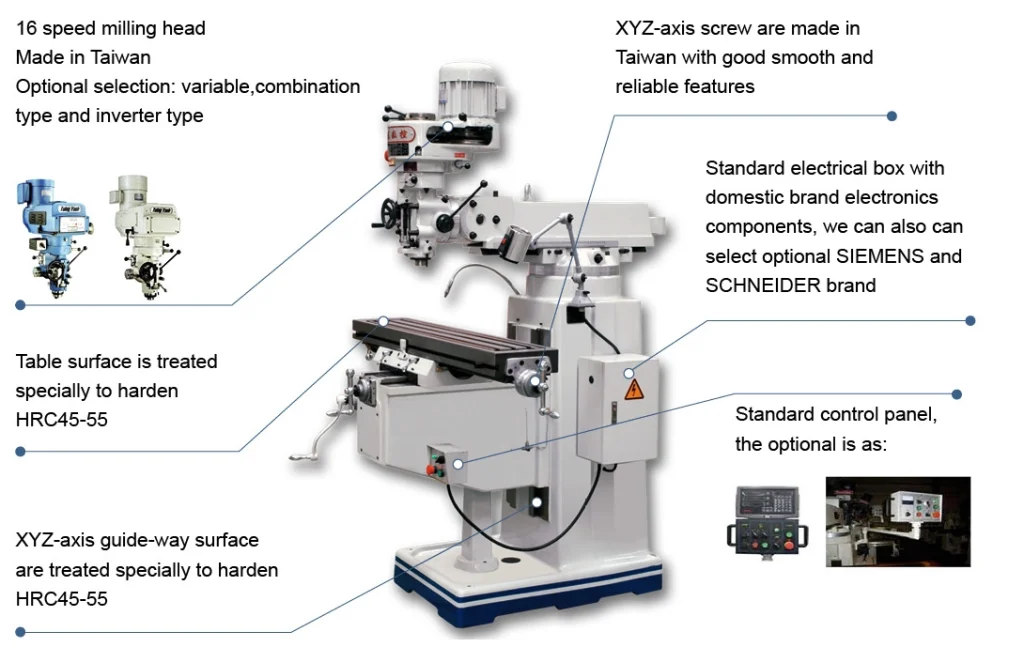

3.Taiwan original milling head and 3 axes Taiwan leadscrews make sure our milling machines performance better than others. NSK P4 bearings are adopted in spindle to improve accuracy of machine and increase the working life.

Product Description :

X6323A

1.Double 55° swallowtail guide way is adopted on both Y, Z-axis, so it is easy to adjust and repair.

2.Adopted strengthen rib on both sides of the column that makes the machine rigidly and beautiful.

X6323B

1. 55° swallowtail guide way is adopted on Z-axis, and rectangular guide way on Y-axis.

2. Adopted strengthen rib on both sides of the column, that makes the machine rigidly and beautiful.

X6325

1. Rectangular guideway on Y and Z-axis is featured a good rigidity and stability.

2. The guideway on saddle is lined with TF wear.

X6325B

1. Rectangular guideway on Y-axis and 55°swallowtail guideway on Z-axis. It makes the machine stably and easy to adjust.

2. The guideway on saddle is lined with TF wearable material.

X6325C

1. Fixed structure is used to connect the mill head without ram, which makes the cut intensity will.

2. Rectangular guideway on Y-axis and 55°swallowtail guideway on Z-axis. It makes the machine stably and easy to adjust.

3. The guideway on saddle is lined with TF wearable material.

X6325D

1. Rectangular guideway on Z-axis is featured a good rigidity and stability.

2. The guideway on saddle is lined with TF wearable material.

XU6325

1. Rectangular guideway on Y and Z-axis is featured a good rigidity and stability.

2. X,Y axis motor 250w. Feed rate: 15, 23, 33, 48, 78, 114, 166, 257(8kinds).

X6330A

1. Fixed structure is used to connect the mill head without ram, which makes the cut intensity well.

2. Rectangular guideway on Z-axis is featured a good rigidity and stability.

3. The guideway on saddle is lined with TF wearable material.

X6333

1. Rectangular guideway on Z-axis is featured a good rigidity and stability.

2. The guideway on saddle is lined with TF wearable material.

Standard Equipment

| drawbar | Handle lubricate | Electrical cabinet |

| Tools and tool box | Working light | 16 speeds milling head |

Optional Equipment

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life