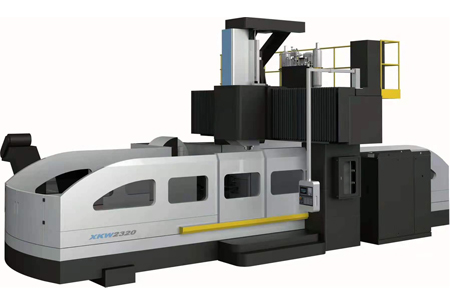

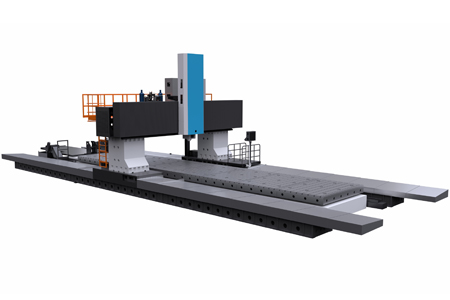

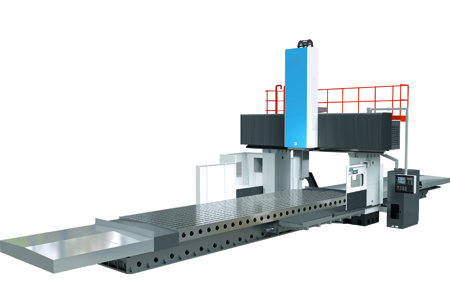

XKW23 series gantry machining center

Table size (WxL) : 1.8*4 m

Max loading : 4-10 Ton

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Model

Parameters |

XKW2316x20 | XKW2316x30 | XKW2316x40 | XKW2322x30 | XKW2322x40 |

| XKW2322Fx30 | XKW2322Fx40 | ||||

| Processing Range | |||||

| Gantry effective width (mm) | 1600 | 1600 | 1600 | 2200 | 2200 |

| X travel (mm) | 2000 | 3000 | 4200 | 3000 | 4000 |

| Y travel (mm) | 1900 | 1900 | 1900 | 2400 | 2400 |

| Z travel (mm) | 800 | 800 | 800 | 1000 | 1000 |

| Spindle nose to table face (mm) | 250~1050 | 250~1050 | 250~1050 | 250~1250 | 250~1250 |

| Table | |||||

| Table size (WxL) (mm) | 1300×2000 | 1300×3000 | 1300×4000 | 1800×3000 | 1800×4000 |

| Max loading (t) | 4 | 5 | 6 | 6 | 10 |

| Table T-slot(no -Size x Distance) | 7-22×170 | 7-22×170 | 7-22×170 | 9-22×180 | 9-22×180 |

| Spindle | |||||

| Ram Form and dimension (mm) | T-Type

Guideway |

T-Type

Guideway |

T-Type

Guideway |

T-Type

Guideway |

T-Type

Guideway |

| SqareRam400x400 | SqareRam400x400 | ||||

| Maximum spindle speed (rpm) | 6000 | 6000 | 6000 | 6000/4000 | 6000/4000 |

| Spindle power (kw) | 15/18.5 | 15/18.5 | 15/18.5 | 22/26 | 22/26 |

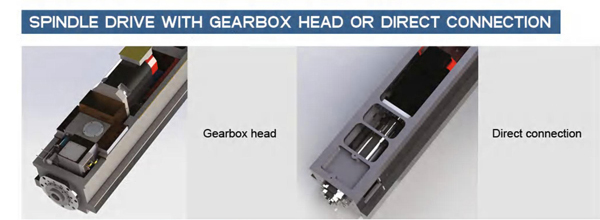

| Spindle Drive Type | |||||

| Spindle taper | BT5O | BT5O | BT5O | BT5O | BT5O |

| ATC(options) | |||||

| Tool capacity (T) | 24/32/40/60 | 24/32/40/60 | 24/32/40/60 | 24/32/40/60 | 24/32/40/60 |

| Maximum tool diameter (mm) | Φ125/230 | Φ125/230 | Φ125/230 | Φ125/230 | Φ125/230 |

| Maximum tool length (mm) | 300 | 300 | 300 | 300 | 300 |

| Maximum tool weight (mm) | 15 | 15 | 15 | 15 | 15 |

| Others | |||||

| Total power supply capaty(KVA) | 50 | 50 | 50 | 60 | 60 |

| Machine weight(T) | 19 | 23 | 26 | 35 | 40 |

| Machine size(mm) | 6500x5500x4500 | 8500x5500x4500 | 10500x5500x4500 | 9000x6000x5500 | 11000x6000x5500 |

| CNC Control System | SIEMENS 828D | SIEMENS 828D | SIEMENS 828D | SIEMENS 828D | SIEMENS 828D |

| FANUC Oi-MF | FANUC Oi-MF | FANUC Oi-MF | FANUC Oi-MF | FANUC Oi-MF | |

| Model

Parameters |

XKW2328x40 | XKW2328x60 | XKW2332x60 | XKW2332x80 |

| XKW2328Fx40 | XKW2328Fx60 | XKW2332Fx60 | XKW2332FxB0 | |

| Processing Range | ||||

| Gantry effective width (mm) | 2800 | 2800 | 3200 | 3200 |

| X travel (mm) | 4200 | 6200 | 6200 | 8300 |

| Y travel (mm) | 3000 | 3000 | 3400 | 3400 |

| Z travel (mm) | 1000 | 1000 | 1000/1250 | 1000/1250 |

| Spindle nose to table face (mm) | 250~1250 | 250~1250 | 250~1250/1500 | 250~1250/1500 |

| Table | ||||

| Table size (WxL) (mm) | 2300×4000 | 2300×6000 | 2500×6000 | 2500×8000 |

| Max loading (t) | 14 | 18 | 24 | 28 |

| Table T-slot(no -Size x Distance) | 11-28×200 | 11-28×200 | 12-28×200 | 12-28×200 |

| Spindle | ||||

| Ram Form and dimension (mm) | T-Type

Guideway |

T-Type

Guideway |

T-Type

Guideway |

T-Type

Guideway |

| SqareRam400x400 | SqareRam400x400 | SqareRam400x400 | SqareRam400x400 | |

| Maximum spindle speed (rpm) | 6000/4000 | 6000/4000 | 6000/4000 | 6000/4000 |

| Spindle power (kw) | 22/26 | 22/26 | 22/26 | 22/26 |

| Spindle Drive Type | ||||

| Spindle taper | BT5O | BT5O | BT5O | BT5O |

| ATC(options) | ||||

| Tool capacity (T) | 24/32/40/60 | 24/32/40/60 | 24/32/40/60 | 24/32/40/60 |

| Maximum tool diameter (mm) | Φ125/230 | Φ125/230 | Φ125/230 | Φ125/230 |

| Maximum tool length (mm) | 300 | 300 | 300 | 300 |

| Maximum tool weight (mm) | 15 | 15 | 15 | 15 |

| Others | ||||

| Total power supply capaty(KVA) | 60 | 60 | 60 | 60 |

| Machine weight(T) | 45 | 55 | 65 | 70 |

| Machine size(mm) | 11000x6500x5500 | 15000x6500x5500 | 15000x7000x6200 | 17000x7000x6200 |

| CNC Control System | SIEMENS 828D | SIEMENS 828D | SIEMENS 828D | SIEMENS 828D |

| FANUC Oi-MF | FANUC Oi-MF | FANUC Oi-MF | FANUC Oi-MF | |

| Model

Parameters |

XKW2337x60 | XKW2337x80 | XKW2342x 60 | XKW2342x80 |

| Processing Range | ||||

| Gantry effective width (mm) | 3700 | 3700 | 4200 | 4200 |

| X travel (mm) | 6200 | 8300 | 6200 | 8300 |

| Y travel (mm) | 3900 | 3900 | 4600 | 4600 |

| Z travel (mm) | 1250/1500 | 1250/1500 | 1250/1500 | 1250/1500 |

| Spindle nose to table face (mm) | 250~1500/1750 | 250~1500/1750 | 250~1500/1750 | 250~15001750 |

| Table | ||||

| Table size (WxL) (mm) | 3000x 6000 | 3000x 8000 | 3000x 8000 | 3000x 8000 |

| Max loading (t) | 28 | 32 | 32 | 36 |

| Table T-slot(no -Size x Distance) | 11-36×250 | 11-36×250 | 11-36×250 | 11-36×250 |

| Spindle | ||||

| Ram Form and dimension (mm) | Square Ram

450×450 |

Square Ram

450×450 |

Square Ram

450×450 |

Square Ram

450×450 |

| Maximum spindle speed (rpm) | 3500 | 3500 | 3500 | 3500 |

| Spindle power (kw) | 22/26(30/37) | 22/26(30/37) | 22/26(30/37) | 22/26(30/37) |

| Spindle Drive Type | ||||

| Spindle taper | BT5O | BT5O | BT5O | BT5O |

| ATC(options) | ||||

| Tool capacity (T) | 24/32/40/60 | 24/32/40/60 | 24/32/40/60 | 24/32/40/60 |

| Maximum tool diameter (mm) | Φ125/230 | Φ125/230 | Φ125/230 | Φ125/230 |

| Maximum tool length (mm) | 300 | 300 | 300 | 300 |

| Maximum tool weight (mm) | 15 | 15 | 15 | 15 |

| Others | ||||

| Total power supply capaty(KVA) | 60 | 60 | 60 | 60 |

| Machine weight(T) | 80 | 85 | 90 | 100 |

| Machine size(mm) | 17000x7500x6800 | 19000x7500x6800 | 17000x8000x6800 | 19000x8000x6800 |

| CNC Control System | SIEMENS 828D | SIEMENS 828D | SIEMENS 828D | FANUC Oi-MF |

| FANUC Oi-MF | FANUC Oi-MF | FANUC Oi-MF | FANUC Oi-MF | |

Resources & Downloads:

XKW23 series gantry machining center Product Introduction :

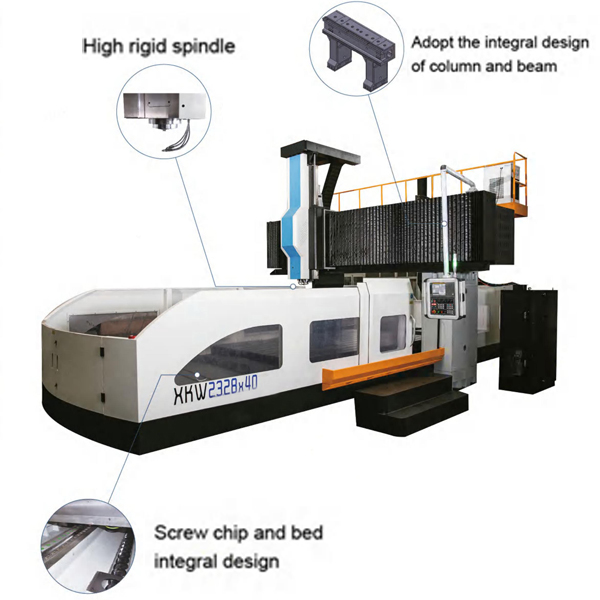

Product Features:

The machine adopts high rigid gantry frame structure, and the important parts are resin sand castings, and through two artificial aging treatment, has enough static and dynamic rigidity and good precision retention.

All three shafts of the machine adopt high precision double nut pre-tightening ball screw, and pre-stretching, driving rigidity is strong, the precision is stable and reliable.

The X/Y axis adopts heavy-duty linear guide rail (ball bal) structure, the Z axis adopts rectangular hard rail structure, and the Z axis is equipped with a diazo liquid balance cylinder, with small motion ineria and fast response speed.

Machine spindle adopts Taiwan high rigid spindle unit, long service life, high reliability, can choose gear head drive or spindle motor direct drive structure.

The machine tool lubrication system adopts the volumetric automatic centralized oil supply lubrication system, which can ensure sufficient lubrication of any lubricating part.

The machine tool lubrication system adopts the volumetric automatic centralized oil supply lubrication system, which can ensure sufficient lubrication of any lubricating part.

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life