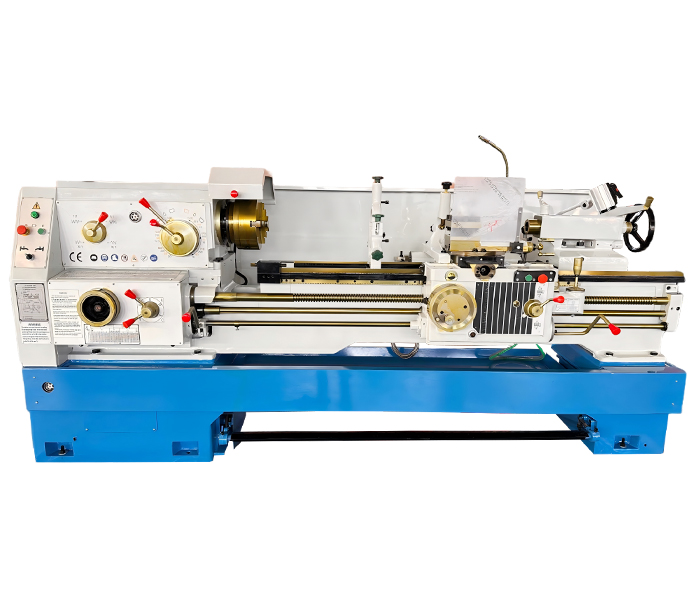

| Main Features |

| 2-Axes Digital Read Out System (DRO) |

| One-piece Meehanite casting machine base. |

| Metric and inch gear box with full range of inch, metric, DP, MP threading and multiple threads, all function shall be reached without changing gear. |

| Apron enforced oil supply with safety device is used to avoid collision. |

| Bed ways & face of compound rest have been ultra-frequency treated & ground to provide longer life. |

| Cross way feeding guides screw: 2 points support for heavy cutting. |

| Length safety foot brake. |

| Dynamically balanced alloy spindle should be adopted by 3-point support. |

| The gears in headstock and spindle should be hardened & precision ground. |

TECHNICAL SPECIFICATION

| Specifications | CA6250Ax1000 |

| Swing Over Bed | 500mm |

| Distance between Center | 1000 mm |

| Swing Over Cross Slide | 300 mm |

| Swing over gap | 720 mm |

| Bed Width | 400 mm |

| Width of Gap bed | 300 mm |

| Spindle Bore Diameter | 52mm |

| Number of Spindle Speed | 24 steps |

| Range of Spindle Speeds | Range of Spindle Speeds: Min: Min:Maxm 80 rpm, Max:Minm 1400rpm |

| Spindle Nose | ISO (GB) D8 |

| Tailstock Travel of Barrel | 150 mm |

| Range of Metric Pitches:Min | Range of Metric Pitches:Min: Max m 0.2mm, Max:Minm 14mm; |

| Range of Diametrical Pitches | Range of Diametrical Pitches:Min: Maxm 8D.P, Max:Minm 44 D.P.; |

| Range of Longitudinal Feeds | Range of Longitudinal Feeds:Min:Max m 0.04 mm /rev., Max:Minm 1.2 mm /rev., |

| Range of Cross Feeds | Range of Cross Feeds: Min:Maxm 0.02 mm /rev., Max:Minm 0.6 mm /rev.; |

| Main Spindle Motor | 10HP (7.5kW) |