In recent years, with the continuous upgrading of the manufacturing industry and the rapid development of intelligent technology, the cylindrical grinder, a traditional processing equipment, has also ushered in unprecedented changes. What we want to discuss today is how to make cylindrical grinding machine stand out in the field of intelligent manufacturing through technological innovation, and become an indispensable core equipment in modern factories.

The traditional cylindrical grinding machine mainly relies on mechanical adjustment and manual operation, which has problems such as limited precision and complicated operation. Nowadays, with the introduction of intelligent control systems, the operation of cylindrical grinders has become easier and more efficient. The latest generation of cylindrical grinding machines are equipped with advanced CNC systems, which can realize fully automatic control of the grinding process. The operator only needs to input the processing parameters through the touch screen, and the system can automatically adjust the grinding speed, feed and grinding wheel angle, which greatly improves the processing accuracy and efficiency.

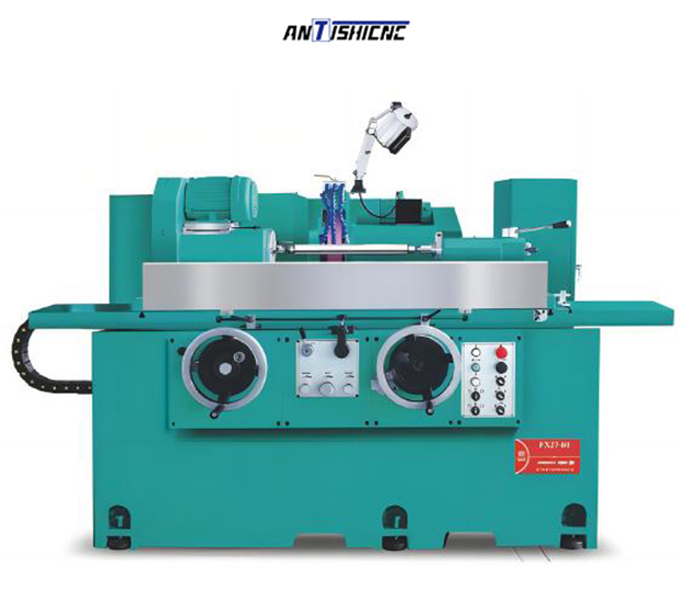

If you have the need to grind bearing products and have the requirement of multiple grinding methods, ANTISHICNC high precision cylindrical grinder FX27-60 can be a reference for you.

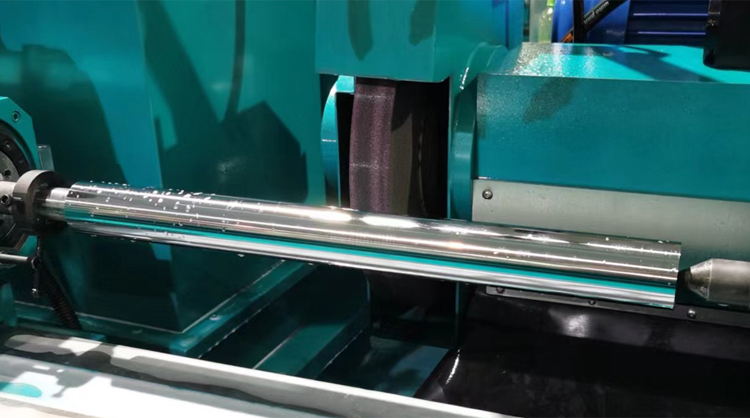

FX27-60 has many kinds of grinding methods, which are: 1. Straight-in grinding, 2. Cross-in grinding, 3. Face grinding, 4. Shoulder grinding, 5. Oblique grinding. In addition, this model not only can only perform external grinding work, but also can perform internal grinding work after installing the ID grinding tool, so if you have the need of internal grinding, you can also choose this machine.

For external grinding, the FX27-60 table has a maximum swivel diameter of 270mm, a maximum length of 600mm, and a maximum grinding diameter of 270mm. for internal grinding, the grinding range varies with different rotational speeds, with a speed of 20,000rpm, the range of the internal grinding diameter is between 25-45mm, and the maximum grinding depth is 100mm. On the other hand, at a higher speed of 30,000 rpm, the internal diameter is 12-25 mm and the depth of grinding is 60 mm.

| FX27-60 Cylindrical Grinding Machine Pictures |

|

|

| Grinding Machine Model NO. | FX27-60 | ||

| ITEM | Description | UNIT | Data |

| Processing capacity | Rotating diameter of bed surface | mm | 270 |

| The distance between the center | mm | 600 | |

| Maximum weight of top center work-piece | Center working(kg) | 60 | |

| Working head only(kg) | 20 | ||

| Maximum line speed | m/s | 35( 65 if high speed wheel) | |

|

Grinding wheel head and feed |

Rotation angle | Left & right | ±15° |

| Standard grinding wheel size | OD X W X ID (mm) | 405*38(32-60)*127 | |

| Special grinding wheel size | ODX W X ID(mm) | 510*38(32-60)*127 | |

| Wheel shaft speed | R.P.M. | 1650(1850/2100)

( infinitely variable speed) |

|

| Moving distance | mm | 250 | |

| Rapid feed stroke | Safety distance(mm) | 25(40 Special model) | |

| Automatic feed | Maximum(mm) | 1.8 | |

| Minimum(mm) | 0 | ||

| Spindle Travel | Feeding per revolution(mm) | 2 | |

| Minimum X- axis setting unit(mm) | 0.005 | ||

| Work head | Spindle rotation | mode | Synchronous/centering |

| Rotation angle | Working edge (degree) | 30° | |

| Grinding wheel edge | 90° | ||

| Spindle rotation speed | R.P.M. | 10-500(Belt wheel regulating) | |

| Center Dimension | MT | NO.4 | |

| Spindle through hole | mm | 25 | |

| Tail stock | Automatic telescopic distance | mm | 32 |

| Centre taper | MT | NO.4 | |

| Work bench

|

Rotation angle | Deg | +9/-6 |

| Hand wheel feed | Feeding per revolution | 12.5 | |

| Automatic feed speed | mm | 50-4000/min | |

| Inner hole grinding device

(Optional) |

Spindle rotating speed | R.P.M. | 20,000(35,000-Special) |

| Motor | KW(HP) | 0.75(1) | |

| Motor | Grinding wheel spindle | KW(HP) | 3.7(5) |

| Working head spindle | KW(HP) | 0.75(1) | |

| Hydraulic power circulating oil pump | KW(HP) | 0.75(1) | |

| Grinding fluid pump | KW(HP) | 0.2(1/4) | |

| Tank volume | Wheel shaft lubrication oil tank | Liter(gallon) | 24(6) |

| Power circulation tank | Liter(gallon) | 60(15) | |

| Grinding fluid tank | Liter(gallon) | 80(20) | |

| Packing Size | L * W * H | mm | 2700×1520 x 1650 |

| Net weight | kg | 2500 | |

| Parts Types that can be ground | ||

|

|

|

If you want to know more about the same product, you can browse our website: https://www.antsmachine.com/fx27-60high-precision-traditional-cylindrical-grinder.html

If you need a grinding machine, please provide the maximum size of the workpiece and the precision requirements, our ANTISHICNC sales team will match the most suitable model for you.