Definition of flange

Flange, short for flange, is a disc-shaped part, usually used for the connection of pipelines, equipment and so on. It is usually made of cast iron, cast steel, stainless steel and other materials. In the pipeline system, the flange is mainly used to connect two sections of pipeline, so that the pipeline can achieve a removable connection between the pipeline, which is convenient for the installation, maintenance and replacement of pipeline components; in the equipment, such as pumps, valves, etc., the flange is used to connect these equipments with the pipeline, so as to achieve the transport and control of fluids.

What is the purpose of the bolt holes in a circle around the flange?

| Connection Fastening |

| Connection fastening connects the two flanges tightly with the help of bolts and nuts to realise the reliable connection of pipeline to pipeline and pipeline to equipment, and to ensure the stability of the system, so that it will not be separated under pressure, vibration and other working conditions. |

| Ensure sealing |

| The bolts are tightened uniformly, so that the sealing gasket is pressurised uniformly and fills the gap between the flanges to achieve a good sealing effect and prevent fluid leakage. |

| Easy to operate |

| It can be quickly positioned and aligned during installation, and can be detached by unscrewing the bolts during maintenance and replacement, which is easy to operate, improves working efficiency and reduces maintenance costs. |

| Positioning Alignment |

| Provide positioning reference for connecting parts, ensure the relative position of flanges is accurate, ensure the axis of pipeline or equipment coincide, make the fluid flow smoothly, avoid resistance increase, equipment vibration and other problems. |

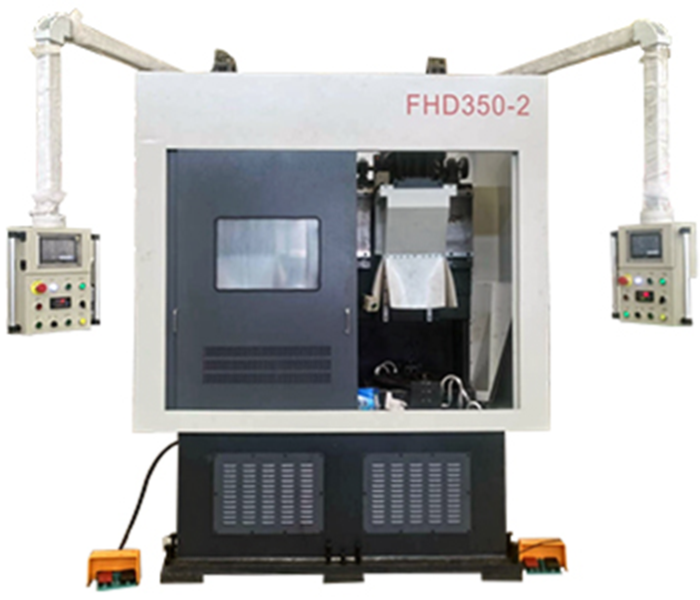

Case Study–FHD350-2 High Speed CNC Drilling Machine for Flanges

Recently, we received an enquiry from a flange manufacturer from South Africa, who asked us whether we could provide them with a solution to help them solve the problem of high-speed drilling of stainless steel flanges with a thickness of 30mm and a diameter of 300mm, so as to realise high-precision mass production, and, after our recommendation, we chose a FHD350-2 high-speed CNC flange special drilling machine for him that could perfectly match his needs.

FHD350-2 high-speed CNC flange drilling machine adopts SIEMENS PLC system and is equipped with corresponding Panasonic servo motor and servo drive. Good compatibility, powerful function and easy operation. It can realise automation, high precision, multi-species and mass production.

| Parameter | FHD350-2 |

| Max. effective processing range | Ø350mm |

| Max. thickness | 100mm |

| Power spindle | |

| Quantity | 2 |

| Spindle taper | BT40 |

| Max. drilling dia. | Ø30mm |

| Spindle speed | 30—3000r/min |

| Spindle motor power | 7.5kW |

| Spindle stroke | 300mm |

The main steps for drilling of flange using PLC drilling machine are as follows:

Pre-preparation

1.Define the flange material, thickness and other parameters, determine the drilling speed, feed and other process parameters.

2.Design and install jigs and fixtures to ensure precision and stability.

3.Select and install suitable drilling bits according to the processing requirements.

4.Write PLC control programme, including spindle speed, feed, positioning and action logic control.

Machining process

1.Clamp the flange blank on the fixture and fix it.

2.Start the drilling machine, PLC control the drill to move to the home position.

3.The drilling machine automatically processes according to the preset parameters and paths, moves to the next hole position after completing one hole, until it is all completed, and monitors the status in real time through sensors and so on during the process.

Post-processing

1.Remove the flange after machining, and test the indicators of the bolt holes with the gauge.

2.Clean up the chips and debris of the drilling machine, lubricate and maintain the moving parts of the drilling machine, check the tool and PLC control system.

Our engineers will work with you to match the most suitable solution for you.

Keywords: Drilling machine, CNC drilling machine, CNC drilling machine for flange machining