| Technical Specifications| Model | GX1-35/50S(Up and down head angle 60°) |

| Cutting capacity(mm) | 0° 350*500 |

| 60° 350*200 | |

| Sawing speed (m/min) | 23/43/62/75 |

| Band saw blade specification (mm) | 4980*1.1*34 |

| Saw Band Tension | manual |

| Total power (kw) | 4.79 |

| Main motor power (kw) | 4 |

| Hydraulic motor power (kw) | 0.75 |

| cooling motor | 40W |

| Oil tank capacity/hydraulic oil L | 75 |

| Oil tank capacity/cutting fluid L | 40 |

| main drive structure | Turbo drive |

| Sawing machine feeding method | Manual feeding |

| Machine control mode | manual manipulation |

| Band saw blade cleaning | Wire brush and chip coolant |

| voltage: | 380V |

| Machine control voltage: | 24V |

| Dimensions (L*W*H) (mm) | 2600×1970×1760mm |

| Machine Weight | 2100kg |

Product Details

This machine tool is a device for sawing metal materials with a bimetallic band saw blade.

It has the advantages of extremely compact structure, fast cutting speed, high precision, narrow sawing kerf, low noise, etc. It is a new type of high-efficiency and energy-saving product replacing circular saws and bow sawing machines. Widely used in electromechanical, metallurgy, automobile, bridge, ship and other industries for sawing various ferrous and non-ferrous metal materials, especially for automatic sawing of long profiles.

Features

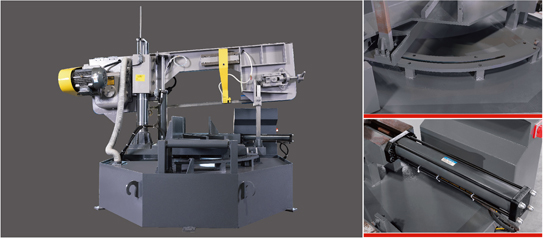

According to the purpose of each part, the machine tool is divided into the following parts: main transmission part, saw band tensioning machine pole, clamping machine pole, saw frame, cooling system, hydraulic system, lubrication system, electrical system, etc.

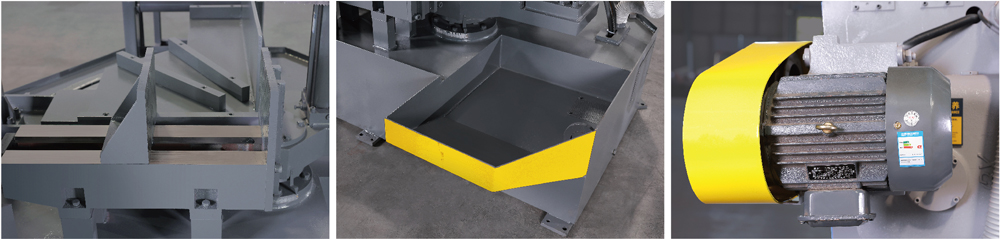

Main drive part: GX1-35/50S head and head angle 60° The main drive of the band sawing machine adopts the motor, belt pulley, and worm gear box to drive the saw wheel to rotate. Through stepless speed regulation, various linear speeds of the band saw blade can be obtained to meet the requirements of sawing. The saw blade line speed requirements of the same material.

Saw band tensioning pole: The saw band is tensioned manually, and the manual tension cylinder drives the driven wheel to move in the tension seat, thereby tensioning the saw blade.

Clamping machine pole: The workpiece is clamped automatically by hydraulic pressure, which is divided into movable vise and fixed vise. When the feeding action is performed, the movable vise is released, which can effectively avoid the friction between the vise and the workpiece, and improve the accuracy of the feeding length. sex and stability.

Saw frame: The saw frame is a bow-shaped structure, which is divided into left and right saw frame boxes and beams. The saw frame plate is made of high-quality steel plates and welded through reasonable reinforcement ribs. After vibration aging, the welding stress will be redistributed and eliminated. Thereby ensuring the stability of the saw frame. The driving wheel, tensioning wheel, and left and right guiding devices are all installed on the saw frame. When the machine tool is working, the saw wheel rotates counterclockwise.

Guide device: The guide of this machine tool is divided into movable guide arm and fixed guide arm, and the movement of the movable guide arm is manually adjusted. Turn the movable guide arm close to the maximum sawing size of the workpiece and then rotate the locking handle to fix it. The locking of the guide arm is manually locked by a dovetail block. The top and sides of the guide seat are made of hard alloy, and there is also a pre-guiding device to ensure the stability of the guide and prolong the service life of the saw blade.

Cooling and chip removal: In order to facilitate the sawing cooling of the machine tool and the collection of chips, the coolant can be automatically recovered and recycled to ensure environmental protection requirements.

Hydraulic system: This machine tool is designed with a hydraulic station, which is responsible for the hydraulic action of the machine tool and the entire production line. All valve components are installed on the same centralized block, and the action of each solenoid valve is controlled by the electrical system to realize the work of the machine tool and the production line.

The hydraulic station is mainly composed of 1 oil tank, 1 hydraulic motor, 1 oil pump, 1 speed control valve, 1 overflow valve, multiple solenoid valves, etc.

Lubrication system: In order to make the machine tool work normally, the machine tool should regularly add lubricating oil to the corresponding parts. The main lubricating parts and lubrication cycle are as follows: Worm gear box: Lubricate with gear oil, replace it once a year;

Guide column: Lubricate with engine oil, add oil in the oil cup every month;

Electrical system: The machine tool adopts a separate control cabinet, and all operations are realized by buttons. The electrical operation is divided into jog and manual. The manual is mainly used for the adjustment of the machine tool and the sawing of the head and tail of the material. There is an interlock between the electrical actions to ensure the safety of the machine tool operation. According to the electrical safety standard, all electrical components are installed in the electrical cabinet, which has the function of opening the door to cut off power, and the components in the operation box are all 24V DC. It has 3C certification for a complete set of low-voltage electrical appliances, and the safety of electrical equipment meets national and international standards.

The machine tool has overload protection and broken belt safety protection device.

Main Parts for the saw machine

| NO. | Part Description | Brand/Origin |

| 1 | Main motor | China |

| 2 | Hydraulic motor | ELITE |

| 3 | Turbo box | BX |

| 4 | Electromagnetic valve | YUEYU |

| 5 | Transformer | CHNT |

| 6 | Contactor | CHNT |

| 7 | Small relay | CHNT |

| 8 | Combination switch | CHNT |

Standard Equipment of the machine

1. Blade cleaning brush.

2. Working light

3. Saw frame height selector gauge

4. Out feed with auxiliary plate table

5. One piece of bi-metal saw blade.

6. One set of tools with tool box

7. Roller table 1M long