The rocker arm drilling machine is a drilling machine in which the rocker arm can rotate and lift around the column, and usually the headstock moves horizontally on the rocker arm.

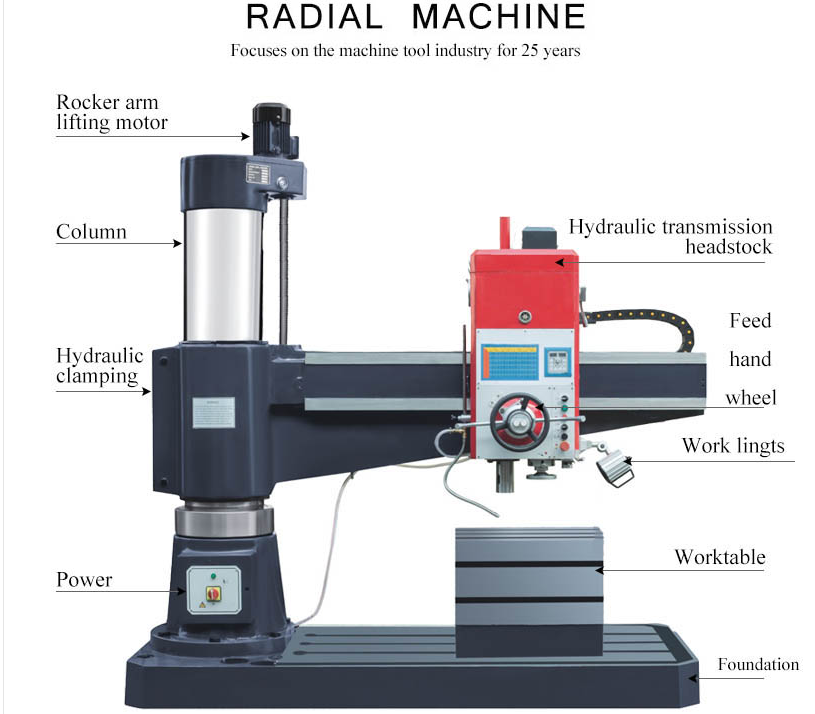

The radial drilling machine is composed of a base, an inner column, an outer column and a rocker arm.

When machining holes on a vertical drilling machine, the centering of the tool and the workpiece is achieved by the movement of the workpiece, which is obviously very inconvenient for some large and heavy workpieces; and the radial drilling machine can be used to move the position of the tool axis. Come to center, which brings great convenience to machining holes on large and heavy workpieces in single-piece and small-batch production. It can also be called a radial drill. It is a kind of hole processing equipment, which can be used for various forms of processing such as drilling, reaming, reaming, tapping and scraping end faces. According to the clamping structure of machine tools, radial drills can be divided into hydraulic radial drills and mechanical radial drills. Among all kinds of drilling machines, the radial drilling machine is easy to operate, flexible, and has a wide range of applications. It is typical, especially suitable for single-piece or mass production of hole machining of large parts with porous holes. It is a common machine tool in general machining workshops.

The spindle box can move left and right on the rocker arm and rotate around the column with the rocker arm (see picture). The rocker arm can also be lifted up and down along the outer column to adapt to the processing of workpieces of different heights. Smaller workpieces can be mounted on the table, and larger workpieces can be placed directly on the machine base or on the ground.

Radial drilling machines are widely used in single-piece and small and medium batch production to process holes in workpieces with large volume and weight. The radial drilling machine has a wide processing range and can be used to drill various screw holes, threaded bottom holes and oil holes of large workpieces. The radial drilling machine is used to process small and medium-sized holes on heavy workpieces or porous workpieces. It is mainly composed of a base, a column, a rocker arm, a spindle box, and a spindle workpiece table. When the rocker arm drilling machine is working, the rocker arm can rotate around the column, and the spindle box can move radially on the rocker arm. This allows the drill to be aligned with the axis of each hole being machined for hole machining. Use more flexible. Generally, when drilling a workpiece, the workpiece is often clamped on the worktable. When machining large workpieces, the workpiece can be clamped on the base of the drilling machine. Depending on the height of the workpiece, after the locking device is released, the rocker arm can move up and down along the column, so that the spindle box and the drill head are at the proper height.

Daily maintenance

1. Clean the appearance and dead corners of the machine tool, disassemble and wash each cover, and require clean inside and outside, no rust, no yellow robes, and the paint sees its natural color and iron sees light. Clean the rail surface and remove the burr on the work surface. Check and fill up screws, handballs, and hand boards, and check the flexibility and reliability of each handle.

2. Maintenance of the spindle feed box of the radial drilling machine: check the oil quality, keep it in good condition, and the oil quantity meets the requirements. Remove burrs from spindle taper holes. Clean the hydraulic transmission system, oil filter screen, and adjust the oil pressure.

3. Inspection of the rocker arm and lifting and clamping mechanism of the radial drilling machine: Check and adjust the lifting mechanism and clamping mechanism to be sensitive and reliable.

4. Inspection of the lubrication system of the radial drilling machine: to clean the linoleum, it is required that the oil cup is complete, the oil circuit is smooth, and the oil window is bright.

5. Check the cooling system of the radial drilling machine: clean the cooling pump, filter and coolant tank. Check the coolant line and make sure there is no water leakage.

6. Inspection of the electrical system of the radial drilling machine: clean the dust inside and outside the motor and electrical box. Turn off the power, open the door cover of the electrical appliance, and check whether the electrical connectors and electrical components are loose or aged. Check that the limit switches are working properly. Whether opening the door and power off will work. Check whether the hydraulic system is normal and whether there is oil leakage. Whether the electrical control switches are normal.

7. Check the oil quality, keep it good, and the oil quantity meets the requirements.

8. Remove the burr of the spindle taper hole.

9. Clean the hydraulic shifting system, oil filter screen, and adjust the oil pressure.

10. Remove the impurities on the main shaft and fill the main shaft with oil to ensure the lubrication of the main shaft.

Vist our website please for the product detail https://www.antsmachine.com/radial-drilling/

For more questions or inquiry, please check with ANTS Machine Sales via contact@antsmachine.com