The CNC EDM Drilling Machine is suitable for processing hard materials with conductive properties, using copper tubes to make continuous vertical movements up and down. The processing diameter is usually in the range of 0.10~3.0mm. EDM drilling machines can be used in the tool and mold manufacturing industry, aviation and aerospace industry, machine tool manufacturing, glass industry, automotive manufacturing and pharmaceutical industries. The main applications can be initial drilling, nozzle holes, exhaust holes, cooling holes for plastic tools, and vacuum holes for turbine shovels. The following is introduced to you by Shanghai ANTISHICNC engineers:

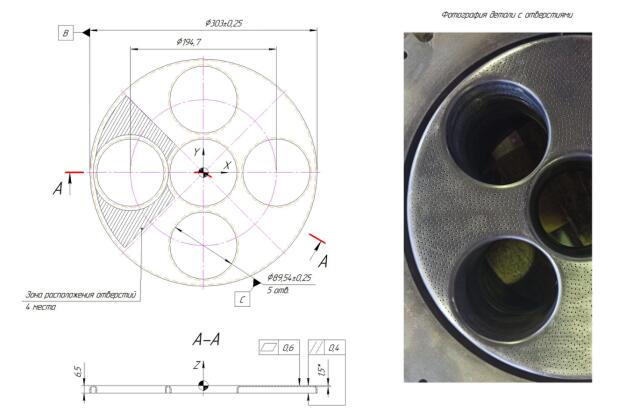

As shown in the picture, the following is the customer’s description of the processing: The plate has 2256 small holes with a diameter of 0.76+0.08mm. The surface hole positioning tolerance is +0.125mm. The hole is at an angle of 90 degrees and 30 degrees to the workpiece surface. There is a zero angle on the horizontal plane. The mark “1.5*” indicates the thickness of the sheet from which the workpiece is made. The markings “0.6” and “0.4” indicate deviations from parallelism to flat surfaces and workpiece side walls.

Based on the above requirements of the customer, Shanghai ANTISHICNC engineers matched the DZ703 CNC drilling machine for the customer. The modified machine can ensure the high precision of the hole diameter, the verticality and cylindricity of the hole, as well as the absence of burrs and deviation. The hardened steel can also be processed by EDM, which can avoid the quenching deformation of the traditional plate that is punched first and then quenched. Even difficult-to-cut materials such as tungsten, titanium, Inconel, nickel-based alloys, stainless steel alloys and molybdenum can be machined. Using Shanghai ANTISHICNC EDM machine tools, the entire process is accurately controllable without the need to set the precise penetration depth in advance.

| Items | Machine tool specifications | DZ703 |

|

Parameters |

X/Y axis travel | 400×300mm |

| Z-axis travel | 300mm | |

| Secondary stroke of spindle | 360mm | |

| Table size | 420X320mm | |

| Load bearing of workbench | 200kg | |

| Overall dimension | 1300X1200X1800mm | |

| Electrode clamping diameter range | Ø0.3 – Ø3.0mm | |

| Operating Weight | 700kg | |

| Working fluid | Tap water/distilled water | |

| Working fluid tank capacity | 45L | |

|

Processing index |

Processing depth | 0-300mm |

| Maximum depth diameter ratio | 300:1 | |

| Maximum processing speed | 60mm/min | |

| Maximum processing current | 30A | |

| Maximum power consumption | 3.6KVA | |

| Working pressure | 8 Mpa | |

| Power input mode | 380/50 V/HZ | |

|

Configuration |

X/Y axis control | Grating ruler DRO |

| Z-axis control | Subdivision stepping motor control | |

| Secondary stroke control mode | AC reduction motor control | |

| Digital display | 3-axis DRO | |

| Filtering method | Replaceable gap type | |

| Water pump | Special plunger pump | |

| Ball screw | Taiwan,China | |

| Linear guide rail | Taiwan,China | |

| Guide plate | Taiwan,China | |

| Motor rotating head | Taiwan (tungsten steel material) | |

| Transformer | 3.6KW enhanced | |

| Resistance | 300W super large non-inductive resistor |

Shanghai ANTISHICNC can provide timely technical support, training and spare parts supply. We only produce high quality CNC drilling machines!

Tags: CNC drilling machines, EDM drilling machine,CNC EDM drilling machine,