The machining motion of the mechanical radial drilling machine can be divided into three parts: main motion, feed motion and auxiliary motion.

1. The main motion is the rotational motion of the main shaft.

2. The feed movement is the longitudinal movement of the spindle.

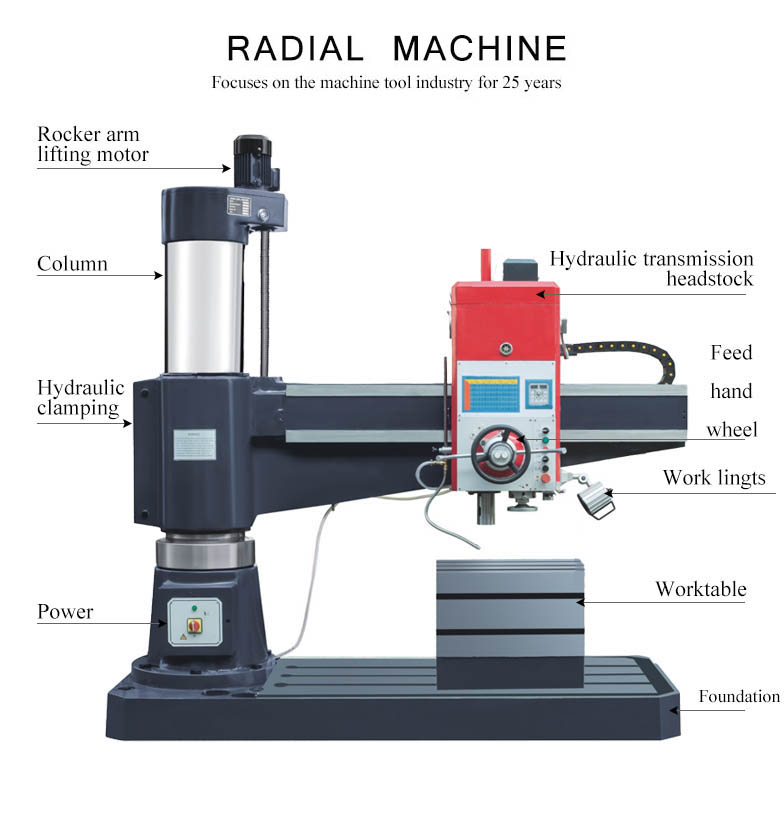

3. Auxiliary movements include: the vertical movement of the rocker arm of the radial arm drilling machine along the outer column, the radial movement of the headstock along the rocker arm, and the rotary motion of the rocker arm and the outer column relative to the inner column.

The main movement and the feed movement are driven by a three-phase asynchronous motor. In order to meet the requirements of various processing methods, the main movement and the feed movement should have a relatively wide speed regulation range. The low-speed movement of the spindle of the radial drilling machine is mainly used. It is suitable for processing forms such as threading, reaming, and reaming on the workpiece, and the speed regulation of the radial drilling machine is also realized by a three-phase asynchronous motor and a gearbox. When machining threads on a radial drilling machine, the main shaft is required to be able to rotate forward and reverse, but the main motor has only one direction of rotation, which needs to be achieved through mechanical conversion. The lifting of the rocker arm is driven by another asynchronous motor, and there must be forward and reverse rotation.

Auxiliary movements are mainly reflected in various movements during drilling. The spindle box of the radial drilling machine is required to be fixed on the rocker arm, the outer column is fixed on the inner column, and the rocker arm is fixed on the outer column. The clamping and loosening of these moving parts are A gear pump is driven by the motor to supply the pressure oil required by the clamping device, and the rotation of the rocker arm and the left and right movement of the headstock are all auxiliary movements.

Now let’s understand how these movements happen?

1. Spindle with tool rotation and feed movement

The rotation and feeding of the main shaft are driven by a three-phase AC asynchronous motor, and the rotation direction of the main shaft is controlled by mechanical and hydraulic devices.

2. The displacement movement of each moving part

The displacement movement of the spindle in the three-dimensional space includes the horizontal movement (translation) of the headstock along the direction of the rocker arm; the lifting movement of the rocker arm along the outer column (the lifting movement of the rocker arm is driven by a cage-type three-phase asynchronous motor); The outer column drives the rotary motion of the rocker arm along the inner column (manually), and the displacement movement of each moving part is used to realize the tool setting displacement of the main shaft.

3. Clamping and loosening of moving parts

There are three kinds of tool setting shifting devices of the radial drilling machine. When the tool is moved, the device needs to be loosened, and during the machining process, the device needs to be clamped. The three sets of clamping devices are rocker arm clamping (between the rocker arm and the outer column); headstock clamping (between the headstock and the rocker arm guide rail); column clamping (between the outer column and the inner column). Usually the clamping and loosening of the headstock and column are carried out at the same time. The clamping and loosening of the rocker arm should be combined with the lifting motion of the rocker arm.