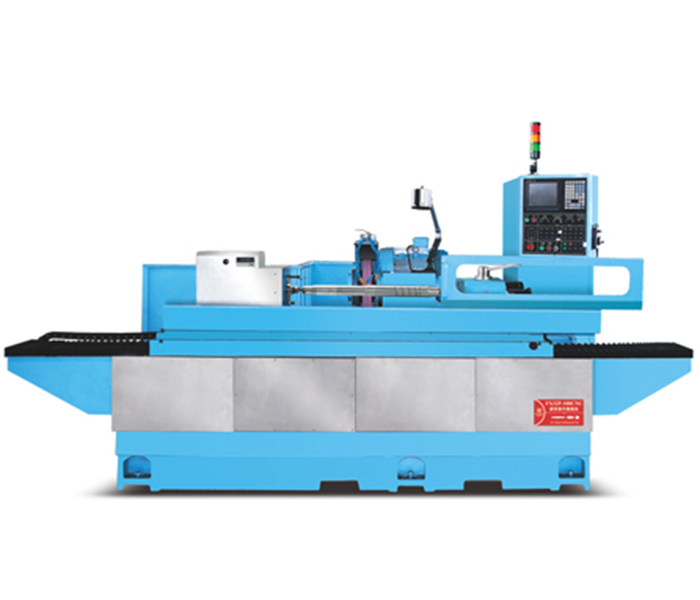

The guideway grinder adopts Taiwan’s advanced machine tool structure manufacturing technology, and is equipped with a series of high-precision and high-efficiency machine tools produced by strict quality inspection methods. The machine tool has good performance, reliable structure, simple operation and convenient maintenance. It can be used for the plane, The grinding of inclined surfaces, bottom surfaces, etc. is suitable for the grinding and finishing of various types of bed, template, flat plates, etc.

1. The working principle of guide rail grinder

Guideway grinders generally use high-precision rolling bearings for the main shaft components of medium and small-sized CNC milling machines, heavy-duty CNC milling machines use hydrostatic bearings, high-precision CNC milling machines use gas hydrostatic bearings, and spindles with a speed of 20000r/min use magnetic bearings or Ceramic ball bearings made of silicon nitride.

Lubrication of the main shaft. In order to ensure good lubrication of the main shaft, reduce frictional heating, and at the same time take away the heat of the main shaft components, a circulating lubrication system is usually used. Use a hydraulic pump to supply oil for strong lubrication, and use an oil temperature controller in the oil tank to control the oil temperature. Nowadays, the spindles of many CNC milling machines are lubricated by advanced lithium-based grease. Each time grease is added, it can be used for 710 years, which simplifies the structure, reduces the cost, and is easy to maintain. However, it is necessary to prevent the mixture of lubricating oil and grease, usually using a labyrinth Type sealing method.

2. Features and advantages of rail grinder

1. The machine tool adopts a closed frame structure with sufficient rigidity

2. The rail surface of the worktable is pasted with a special machine tool rail plate to ensure that the table feed does not crawl and the rail durability

3. The horizontal feed and vertical feed of the grinding head are driven by a servo motor with a ball screw to ensure high feed accuracy of the machine tool and improve ease of operation

4. The feed hydraulic system of the worktable uses mechanical valves for reversing, and the reversing distance of the machine tool is constant

5. The machine tool adopts a humanized operation control panel to improve the ease of operation of the machine tool

6. The horizontal Y and vertical Z coordinate movements of the rail grinder are equipped with digital display devices, which are convenient for operation and measurement, and ensure the machining accuracy of the machine tool.