CNC lathe play an important role in the manufacture of marine propellers and propeller shaft systems. CNC lathe can accurately process the shape of propeller blades according to pre-designed complex curves and surfaces, ensuring the geometric accuracy and surface quality of the blades, thereby improving the fluid dynamics performance of the propeller.

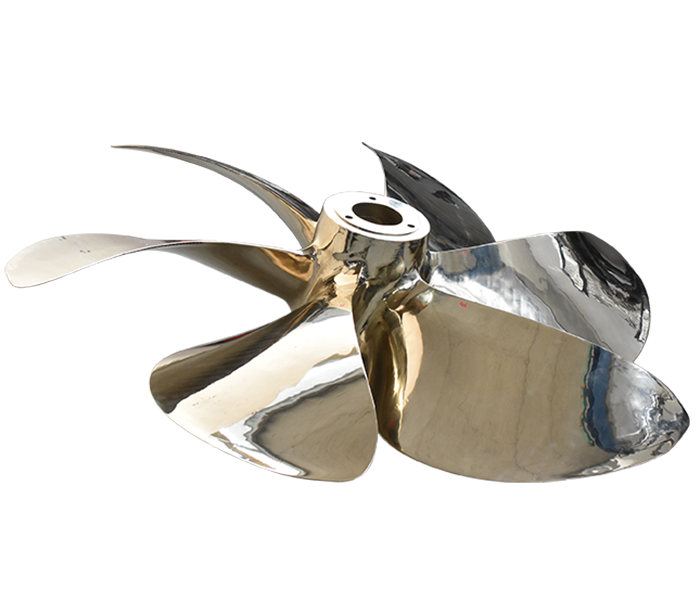

Recently, Shanghai ANTS Machine Equipment Co., Ltd. received a Greek customer. The customer requested to use a CNC lathe to make marine propellers. The propeller diameter is 1000mm-1500mm and the length is 500mm. The engineers of Shanghai Antis matched a suitable CNC face lathe for the customer: CK64200.

The CK64200 CNC face lathe uses the world-renowned German SINUMERIC 828D CNC system and full digital AC servo system. The main motion of turning is a four-speed stepless speed change, and the X and Z axes are both semi-closed loop controlled. The ball screw pair uses domestic precision ball screws, which makes the machine tool have good positioning accuracy and repeat positioning accuracy.

Whether in terms of overall performance, technological advancement, and the selection of supporting parts, this machine tool is an excellent product among the same specifications at home and abroad.

| Specifications | Ck64200 |

| Max. Swing over bed | φ2000 mm |

| Swing over cross slide | φ1600 mm |

| Max.load between centers | 5000 kg |

| Spindle inner hole diameter | φ100 mm |

| Chuck diameter (tiger claw) | φ2000 mm |

| X-axis (cross slide) stroke | 1050 mm |

| Z-axis (large slide) stroke | 1000 mm |

Next, Shanghai ANTISHICNC enginee rwill introduce you to the detailed processing process:

1.Design and modeling:

Use professional CAD software to design the three-dimensional model of the propeller and propeller shaft according to the performance requirements and power system parameters of the ship, and determine its technical requirements such as shape, size and tolerance.

2.Process planning:

Develop a processing route based on the material, shape and precision requirements of the parts, including selecting tools, determining cutting parameters, arranging processing sequences, etc.

3.Programming

Convert the process plan into a processing program that can be recognized by the CNC lathe, and use instructions such as G code and M code to control the movement and action of the machine tool.

4.Blank preparation

Select suitable raw materials and perform preliminary forging, casting or cutting to obtain a blank close to the final shape.

5.Clamping and positioning

Mount the blank on the workbench of the CNC lathe, and use a special fixture for positioning and clamping to ensure stability and precision during processing.

6.Rough machining

Use a larger cutting depth and feed speed to remove most of the excess material and initially form the general shape of the part.

7.Semi-finishing

Reduce the cutting depth and feed speed to further improve the accuracy and surface quality of the parts in preparation for finishing.

8.Finishing

Use fine tools and optimized cutting parameters to perform the final cutting process to achieve the accuracy and surface roughness required by the design.

9.Inspection and quality control

Use precision measuring equipment such as three-coordinate measuring machines to inspect the size and shape of the processed propellers and propeller shafts to ensure that they meet the design requirements.

10.Surface treatment

According to needs, perform surface treatment on the parts, such as polishing, chrome plating, etc., to improve the corrosion resistance and service life of the parts.

For more technical details and CNC lathe knowledge, please contact Shanghai ANTS Machine Equipment Co., Ltd. We provide customers with timely technical support, training and high-quality lathes.

Official website of CNC lathe CK64200:

Keywords: lathe, CNC lathe processing propeller, CNC face lathe