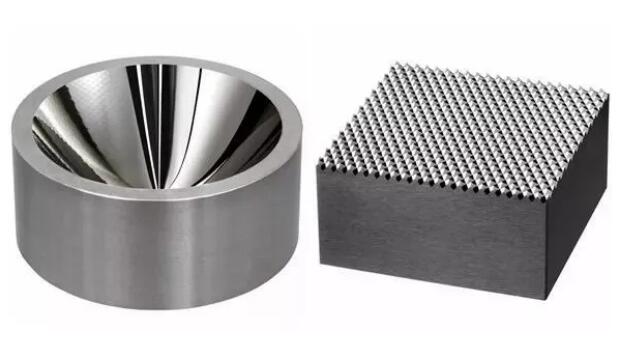

How does superstring finishing technology improve finishing efficiency? The purpose of CNC finishing is to ensure the final dimensional accuracy and surface quality of the workpiece. The surface quality of finishing depends largely on the height of the residual ridge left after processing. Th...... [Read More]

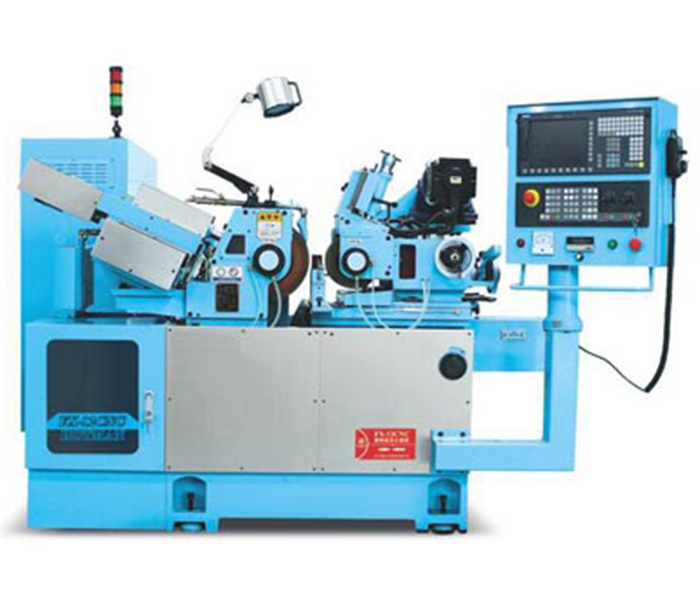

How to reduce CNC finishing time from 60 minutes to 4 minutes?

Reported by: ANTISHICNC Date: September 27, 2021