| Item |

Unit |

DTM-B70 |

| Processing range |

| Swing over bed |

mm |

Φ700 |

| Maximum rotation diameter (the lower tool holder does not install the tool seat at the corresponding position) |

mm |

Φ440 |

| Maximum cutting diameter of upper tool post |

mm |

Φ700 |

| The maximum cutting diameter of the lower turret |

mm |

Φ440 |

| Maximum cutting length of upper tool post |

mm |

1580 |

| Maximum weight of shaft parts |

kg |

1500 |

| Spindle |

| Chuck size |

|

12″ (optional 15″) |

| Spindle head type |

|

ISO A2-11 |

| Spindle speed range |

r/min |

0~3500 |

| Spindle front bearing diameter |

mm |

Φ240 |

| Spindle through hole diameter |

mm |

Φ102 |

| Through bar diameter |

mm |

Φ90 (when hollow chuck and hollow cylinder are selected) |

| Spindle Taper-Hole Taper |

|

Metric 120 |

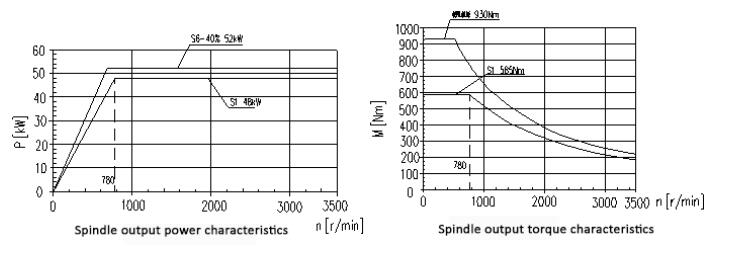

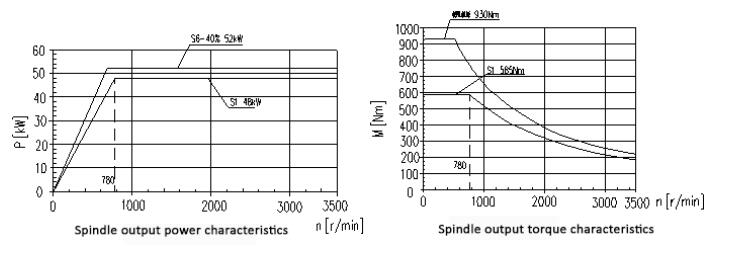

| Spindle power S1/S6 |

kW |

48/52 |

| Spindle torque |

Nm |

585(S1),795(S6),930(MAX) |

| Spindle characteristic curve

(Spindle characteristic curve when using Siemens 840Dsl CNC system (with 1FE1145)) |

|

| Sub-spindle (optional) |

| Sub-spindle chuck size |

|

10″ (optional 12″) |

| Sub-spindle head type |

|

ISO A2-8 |

| Sub-spindle speed range |

r/min |

0~4000 |

| Sub-spindle front bearing diameter |

mm |

Φ200 |

| Sub-spindle through hole diameter |

mm |

Φ60 |

| Sub-spindle taper hole taper |

|

Metric 100 |

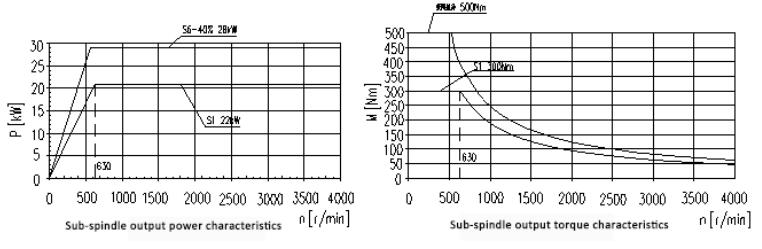

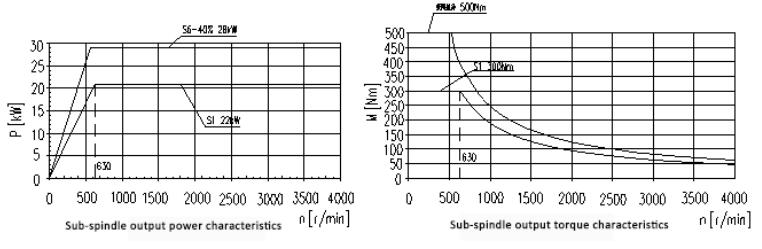

| Sub-spindle power S1/S6 |

kW |

22/28 |

| Counter spindle torque |

Nm |

300(S1),384(S6),500(MAX) |

| Sub-spindle travel |

mm |

1600 |

| Sub-spindle characteristic curve

Sub-spindle characteristic curve when Siemens 840Dsl CNC system is used (with 1FE1116, optional) |

|

| B axis |

| B axis rated torque |

Nm |

484 |

| B axis maximum torque |

Nm |

878 |

| B-axis mechanical locking torque |

Nm |

6000 |

| Milling axis |

| Milling Spindle Tool Interface |

|

HSK-T63 (Optional CAPTO C6) |

| Milling axis motor power |

kW |

40(S1) |

| Torque |

Nm |

127.3(S1) |

| Maximum speed |

rpm |

12000 |

| Feed drive |

| Project |

Unit |

X1 axis |

Y axis |

Z1 axis |

X2 axis |

Z2 axis |

W axis |

| Moving speed |

m/min |

36 |

36 |

36 |

16 |

14 |

14 |

| Cutting feed rate |

m/min |

36 |

36 |

36 |

16 |

14 |

14 |

| Maximum stroke of each axis |

mm |

840 |

±210 |

1700 |

252 |

1500 |

1500 |

| Minimum resolution |

mm |

0.001 |

| Project |

Unit |

C1 axis |

C2 axis |

B axis |

| Moving speed |

r/min |

200 |

200 |

40 |

| Cutting feed rate |

r/min |

100 |

100 |

40 |

| Maximum stroke of each axis |

° |

360 |

360 |

±120 |

| Minimum resolution |

° |

0.0001 |

0.001 |

0.0001 |

| Main magazine system |

| Chain magazine capacity |

PCS |

40 (optional 40×2=80) |

| Maximum installed tool diameter×length (the adjacent position has a tool) |

mm |

Ф90×400 |

| Maximum tool diameter x length (no tool adjacent) |

mm |

Ф140×400 |

| Tool to tool change time |

S |

2.4 |

| Chip-to-chip tool change time |

S |

10 |

| Tool weight |

kg |

12 |

| Tool selection method |

Random tool change, shortest path tool change |

| Sub-tool magazine system (optional) |

| Magazine capacity |

PCS |

6 |

| Tool change method |

Milling spindle plug-in tool change |

| Maximum installed tool diameter×length (the adjacent position has a tool) |

mm |

Ф90×700 |

| Tool change time |

s |

8 |

| tool weight |

kg |

15 |

| Lower turret (optional) |

| Turret form |

Servo powered turret |

| Number of turret stations |

|

12 stations |

| Tool change method |

|

According to the shortest path, any tool change, servo motor drive |

| Tool change time (adjacent/furthest) |

s |

0.84/1.42 |

| Shank size |

mm |

25×25 |

| Inner Hole Shank Size |

mm |

Maximum φ40 |

| Tailstock |

| Maximum stroke |

mm |

1500 |

| Tailstock thrust |

N |

0~17000 |

| Mandrel taper |

|

MT. NO.5 |

| Tailstock drive |

Servo motor drive |

| Center frame (optional) |

| Clamping range |

mm |

Ф100-Ф410/or Ф135-Ф460 |

| The diameter of the workpiece that can be processed by the machine tool after adding the center frame |

mm |

700 (full stroke does not affect the maximum machining diameter of the machine tool) |

| travel range |

mm |

1500 |

| Steady frame drive mode |

Servo motor drive |

| Machine tool protection |

| The machine tool protection device is safe, complete and reliable, in line with GB15760-1995 “General Technical Conditions for Safety Protection of Metal Cutting Machine Tools”, the electric control cabinet is cooled by air conditioner, sealed and dustproof |

| Machine noise |

|

In line with national standards <75dB (A) |

| Degree of protection |

|

IP54 |

| Lubrication system |

| Quantitative automatic centralized lubrication device is adopted to implement forced lubrication for each sliding surface and rolling surface, among which XYZ ball screw is lubricated by oil and air. When the oil level in the lubricating oil tank is too low (lack of oil), the machine tool displays an alarm |

| Lubricating oil |

|

L-G68 guide rail lubricating oil |

| Lubrication box volume |

L |

6 |

| Lubricating motor power |

W |

25 |

| Cooling system |

| Cooling box volume |

L |

1600 |

| Internal cooling pump 2MPa |

L/min |

28 |

| External cooling pump 1.2MPa |

L/min |

60 |

| Chip flushing pump 0.5MPa |

L/min |

100 |

| Hydraulic system

(The hydraulic station is equipped with a cooling device, which can ensure the continuous operation of the machine tool for 24 hours) |

| Fuel tank capacity |

L |

250 |

| Hydraulic oil grade |

|

46# anti-wear hydraulic oil |

| Hydraulic pump motor power |

kW |

4 |

| Greatest pressure |

MPa |

8 |

| Chip removal device |

| Automatic Chip Conveyor Form |

Chain plate |

| Installation location |

Side discharge |

| Tricolor warning light |

| Red light |

Show alarm |

| Yellow light |

Show end of program |

| Green light |

Shows that the program is running |

| Electrical System |

| Configure Siemens SIEMENS 840Dsl control system.

The operation panel is 15″LCD display, full keyboard, with electronic handwheel.

Conforms to the standard of GB/T5226.1-1996 “Industrial Machinery and Electrical Equipment Part One: General Technical Conditions”. The system has perfect and reliable interlocking, safety protection, fault diagnosis and alarm functions, and is equipped with RS232 standard communication interface. |

| Voltage |

|

380V ± 5% 50HZ |

| Total power |

KVA |

210 |

| Machine color |

| Machine tool standard color |

Standard color |

| The color requested by the user |

Provide swatches |

| Machine size |

| Machine tool dimensions (length × width × height) |

mm |

5790×3640×3050 (Does not include chip conveyor and external hydraulic station water tank and cooler)

6850×6230×3050 (Including chip conveyor and external hydraulic station water tank and cooler) |

| Machine weight |

kg |

28000 |

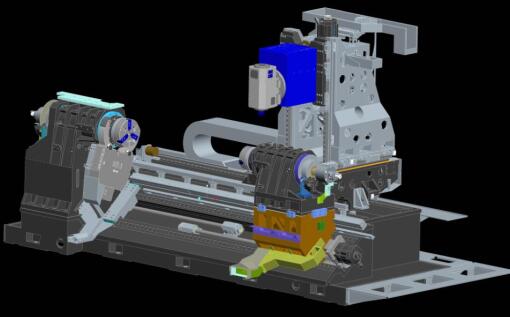

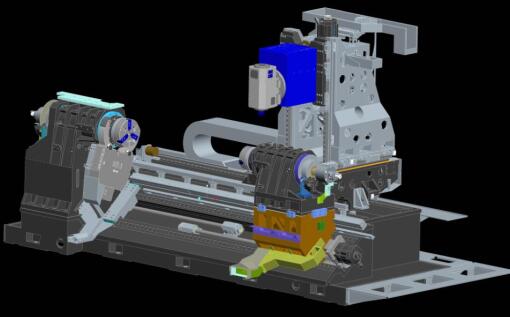

Product Description

DTM-B70 series turn-milling compound machining center is the third generation of orthogonal multifunctional turning-milling compound machining center designed based on the concept of standardization, modularization and serialization. It has the characteristics of high efficiency, high precision and high reliability. According to market requirements, it can be combined with different modules to form a turning and milling center with double spindles, double turrets, single or double steady rest, and a turning center without a tool magazine. Turning-based high-end CNC turning and milling machines. The maximum number of control axes of the machine tool is nine axes, and the maximum number of linkage axes is five axes (X, Y, Z, B, C). This series of machine tools is suitable for the turning of the outer circle, end face, thread, sink groove, and inner hole of various metal shaft parts, as well as the milling of planes and keyways. It can complete various curved surfaces that require multi-axis linkage to process. Efficient roughing and high-quality finishing can provide production-type turning and milling processing capabilities, especially for military, aviation, aerospace, ships, automobiles, railways and other industries with complex shapes and high processing precision parts.

Product Main features

1.Realize the functional integration of one machine and the compounding of multiple processes. It has multi-functional compound processing capabilities such as turning, boring, end milling, end milling, drilling, tapping, etc. It can quickly and high-quality complete the processing of complex workpieces, and its flexibility is especially suitable for the processing of complex, multi-variety and small-batch parts.

2.The combination of various functional components can realize the complete processing capability of six sides. The combination of functions such as B axis, milling axis, main and auxiliary spindles, steady rest, lower tool rest, tool setting instrument, and workpiece measurement will enable the machine tool to have strong compound processing capabilities and detection capabilities. The production capacity of the equipment not only greatly saves time and labor costs, but also reduces the area occupied by the equipment, and greatly improves the processing accuracy and equipment utilization.

3.The main shaft, sub-spindle and milling shaft of the machine tool are powerful, and can provide production lathes and milling processing capabilities.

4.Stationary frame with parking function.

5.High-precision guidance and closed-loop drive system ensure high transmission efficiency, good precision retention, fast and stable movement of the machine tool holder, and high positioning accuracy.

6.Machine tool cooling and heat balance system maximizes machining accuracy and stability. To prevent component deformation, the machine tool is equipped with a cooling device to minimize the generation of thermal displacement.

7.Double tool magazine system effectively expands the processing capacity of a single machine, especially the drilling and boring function;

8.The workpiece and the tool are as close as possible to the operator, which is convenient for observing the cutting, measuring the size and maintaining the tool;

9.The one-button self-cleaning system without dead angle can reduce the maintenance work intensity of the internal processing space of the machine tool and improve the protection life of the machine tool;

10.Automatic sliding door, multi-dimensional operation table, improve the pleasant operation of the machine tool.

Standard Equipment

Roller Linear Guide

Hollow cooled ball screw

Milling spindle and B axis

Servo Tailstock

Chain plate side chip conveyor

Electrical cabinet air conditioner

Warning Light

Semi-closed-loop measuring device

2 Sets-Wheel guards

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.