Technical parameter

| No. | Item | Parameters |

| 1 | Steel plate length | ≤ 12 meters (40 feet) |

| 2 | Steel plate width | ≤ 2500mm wide |

| 3 | Steel plate thickness | 6~14mm thick |

| 4 | Processing speed

(Clean both sides of steel plate at the same time) |

1.0-2.0m/min (A-D grade original surface material and workpiece have different cleaning requirements (stepless frequency conversion speed regulation) |

| 5 | Rust cleaning grade | Sa2 .5 (GB8923-88) |

| 6 | Processing material and strength range | Q235/Q345/65Mn/HT/ZG etc. |

| 7 | Surface roughness | 15~70 μm (depend on shot size) |

| 8 | Compressed air | 2 -4m3/min |

| 9 | Compressed air pressure range | 0.4-0.6MPa |

| 10 | Total power | About 190 kw |

| 11 | Electrical control system | PLC automatic control, one-key operating system, automatic fault detection and alarm function |

| 12 | Pit requirements | Waterproof |

| 13 | Noise | ≤95dB |

Product reference picture

|

|

|

|

Product Details

Application:

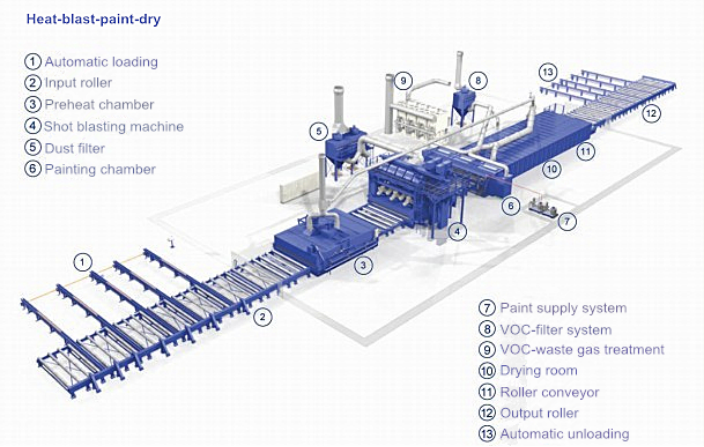

ATS2500 steel plate pretreament line is a specially designed machine used in the surface cleaning for various jobs. It can realize the shot blasting, painting/primer and drying automatically. It includes shot blasting system, painting/ primer.

Features:

The cover adopts a bending and welding structure. An access doorvable doors to repair the lower transmission and eliminate the projectile blockage at the bottom. The hoist shell is wel is provided on the side to repair and replace the hopper. The front and sides of the lower cover are equipped with moded with Q235 plate.

Use tensioning device. Tensioning devices are provided on both sides of the upper part of the hoist, which can easily adjust the belt tightness.

Blanking by centrifugal gravity. During work, the hopper fixed on the conveyor belt scrapes up the pellets at the bottom, sends the pellets to the top, and then drops the material by centrifugal gravity.

Special transmission belt with polyester wire core, high strength and anti-stretch.

The belt pulley adopts a squirrel-cage structure, with a slight protrusion in the middle, and each spoke is processed by chamfering. It not only improves the friction between the lifting tape and the pulley, avoids the slipping phenomenon of the old-style light pulley and the pulley from damaging the belt, but also reduces the pre-tensioning force of the lifting belt and prolongs the service life; meanwhile, it prevents the insertion of scattered bullet Between the pulley and the belt, it affects the transmission.

The elevator is equipped with a back-off mechanism to prevent the hoisting machine from reversing due to power outages and other reasons.

Leave 10% margin for lifting. Because the hoisting machine drops material by centrifugal gravity, each time there is a material fall back into the hoisting machine, the hoisting capacity needs to be increased appropriately.

Machine accessories

| NO. | Item | Qty. | Description |

| 1 | Blasting assembly | 8 sets | Shot blasting turbine, special motor, motor seat, introduction pipe, impeller, blade, protective plate, combination disc, sand retaining disc, sealing mechanism, belt wheel, V-belt, etc. |

| 2 | Blasting chamber | 1set | Steel structure room body, projectile zone combined guard plate, alloy steel cap, protective belt, etc. |

| 3 | Sealing room | 1set | Steel structure room body, observation door, sealing curtain, rubber protection board, etc. |

| 4 | Roller conveyor mechanism | 1set | Sprocket, chain, bearing, drive mechanism, tensioning mechanism, wear-resistant roller table in shot blasting chamber, sheath, sealed chamber roller table, outdoor roller table, sprocket cover, etc. |

| 5 | Separator | 1set | Wind separation mechanism, drive mechanism, air volume regulating valve, tension mechanism, pellet storage hopper, filter and other devices. |

| 6 | Screw conveyor system | 2set | Housing, screw shaft and support, 16Mn blade, reducer drive mechanism, sealing device bearing, etc. |

| 7 | Bucket elevator | 1set | Head drive mechanism, tail drive mechanism, tension mechanism, housing, belt, hopper, bearing, etc. |

| 8 | Supplying shot system | 1set | Projectile controller, polyurethane feeding tube, bottom screw conveyor, etc. |

| 9 | Maintenance platform | 1set | Platforms, columns, ladders, anti-rails,etc. |

| 10 | Dust removal system | 1set | Dust drop chamber, pulse blowback filter cartridge dust collector assembly, fan, pipe, chimney, etc. |

| 11 | Painting chamber | 1set | Frame, spray gun, reducer, transmission mechanism, painting machine, painting pump,etc. |

| 12 | Paint mist treatment system | 1set | Paint mist adsorption system pipeline, etc. |

| 13 | Electrical control system | 1set | Control cabinet, PLC, frequency converter, cable, electrical material, bridge, air control box, pulse controller, etc. |

| 14 | Preheating chamber | 1set | Chamber body, heating mechanism, hot air blowing pipe, etc |