CNC machining centers are divided into vertical machining centers and horizontal machining centers according to their structure. The spindle of the horizontal machining center is horizontal and usually has a square table that can perform indexing and rotary motion. Generally, there are 3 to 5 motion coordinates, and the common ones are three linear motion coordinates plus one rotation motion coordinate, which allows the workpiece to complete the processing of the other four surfaces except the mounting surface and the top surface after one clamping, and process box parts. Generally, there is an indexing table or a CNC conversion table, which can process all surfaces of the workpiece; it can also be used for joint motion of multiple coordinates to process complex spatial surfaces. Some horizontal machining centers are equipped with an automatic exchange table, which can load and unload the workpiece at the loading and unloading station while processing the workpiece at the station, which greatly shortens the auxiliary time and improves the processing efficiency.

After the workpiece is clamped in the horizontal machining center for the last time, the CNC system can control the machine tool to automatically select and replace the tool according to different processing technologies, and automatically change the auxiliary functions such as the spindle speed, feed speed, and the trajectory of the tool relative to the workpiece. The horizontal machining center (2 pieces) with interchangeable worktables completes the multi-process machining of multiple surfaces of the workpiece. And it has a variety of tool changing or tool selection functions, which greatly improves the production efficiency. Due to the concentration of processes and automatic tool change, the machining center reduces the time for clamping and measuring the workpiece and adjusting the machine tool, so that the cutting time of the machine tool reaches about 80% of the machine tool start-up time (only 15-20% for ordinary machine tools); The turnover, transportation and storage time of workpieces between processes shortens the production cycle, and the economic effect is obvious. Machining centers are suitable for small and medium batch production with complex parts, high precision requirements and frequent product replacement.

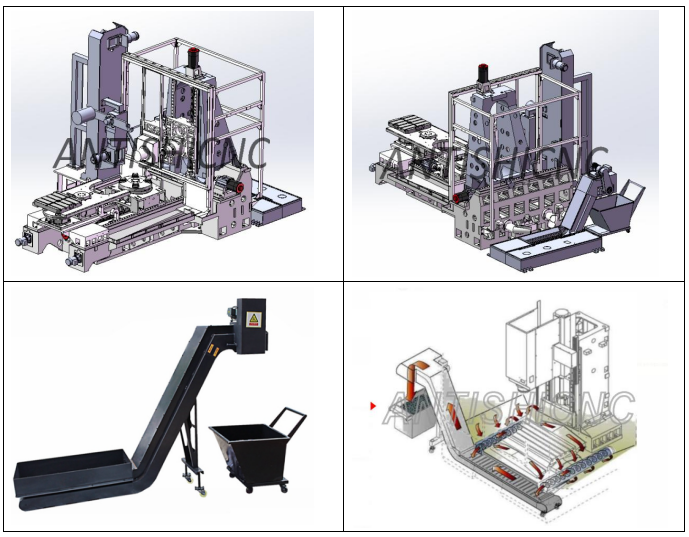

Compared with the vertical machining center, the horizontal machining center has a complex structure, a large footprint and a high price. When the vertical machining center processes the cavity or the concave surface, the chips are not easy to discharge. In severe cases, the tool will be damaged, the machined surface will be damaged, and the smooth progress of the processing will be affected. However, the horizontal machining center is easy to remove chips during machining, which is beneficial to the machining of workpieces. The horizontal machining center chip conveyor is more suitable for chip removal when the chips and cutting fluid contain more oil. The chip removal system of the horizontal machining center of ANTISHICNC Machinery is 2 sets of spiral chip removal and 1 set of chain plate type chip removal machine, which has high chip removal efficiency and high processing efficiency. If necessary, please consult our business department via contact@antsmachine.com

Tags: Horizontal milling machine center; Chip remover; Machining Center