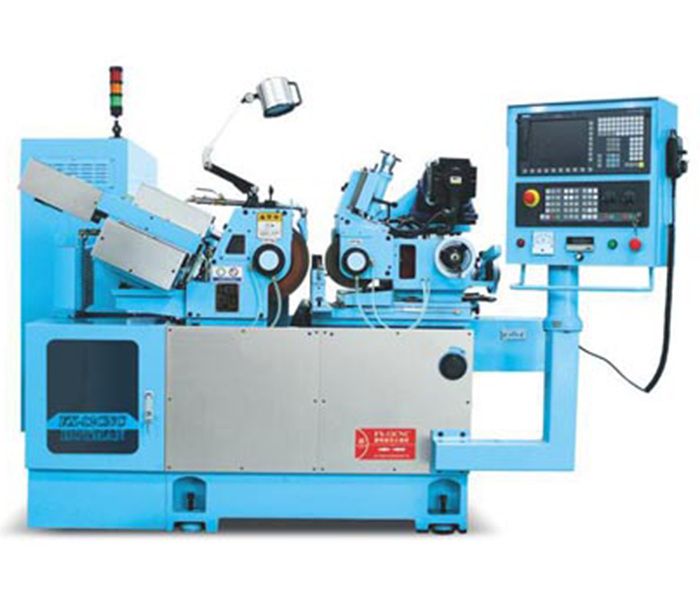

A centerless grinder is a type of grinder that does not require the positioning of the axis of the workpiece to perform grinding. It is mainly composed of three mechanisms: a grinding wheel, an adjusting wheel and a workpiece support. The grinding wheel actually performs the grinding work, and the adjusting wheel Control the rotation of the workpiece and control the feed speed of the workpiece. As for the workpiece support to support the workpiece during grinding, there are several ways to cooperate with these three parts, except for stopping grinding, which are the same in principle.

A centerless grinder with a shortened transverse dimension, which is particularly suitable for use in a small installation space, and can meet the requirements of simplification and space saving of various production lines. Since the grinding wheel dressing unit is arranged at an oblique downward position above the grinding wheel, there is no need to maintain a space for the grinding wheel dressing unit on the side of the grinding wheel, which is most closely related to the lateral dimension of a traditional centerless grinding machine. Therefore, the horizontal dimension of the centerless grinder can be greatly reduced, and the grinder can be installed in a small installation space, thereby meeting the requirements of simplification and space saving of various production lines.

1. The mechanical structure of the centerless grinder

1. Machine base/machine tool

The base is a sturdy heavy cast iron structure that supports the other parts of the machine. It contains the hydraulic oil tank and the grinding wheel head assembly.

Tip: A machine with a solid base will increase the rigidity of the machine and reduce vibration.

2. Rotating disc

The rotating disc is a rectangular cast iron part, which is mounted on the base with a trunnion. Through the adjustment dial, the adjustment wheel can be aligned with the grinding wheel correctly.

3. Grinding wheel

The grinding wheel is a cutting tool used to remove part of the workpiece. It is made of abrasive grains and bonding agent.

Grinding wheel dresser The grinding wheel dresser is installed behind the grinding wheel and uses diamonds to dress the grinding wheel.

4. Grinding head

The grinding head that fixes the grinding wheel is a movable shell, which is fixed on the base with bolts.

5. Spindle in the wheel head

There is a main shaft supporting the grinding wheel in the grinding wheel head. The high-precision spindle supports and rotates the grinding wheel.

6. Sliding rail

The slide rail installed on the rotating plate is used to control the adjusting wheel and the workpiece holder, and simultaneously advance or retract to the grinding wheel.

7. Upper slide

It is installed on the sliding rail to control the direction of the adjusting wheel to or away from the workpiece holder. It contains the drive for adjusting the wheel.

8. Double compensation feed components

The dual-compensation feed component is composed of two precision ball threaded rods and is installed on the upper and lower rails. This component is used to adjust the machine to fit the size of the workpiece.

9. Adjustment wheel

The adjusting wheel is made of rubber bond mixed with abrasives. It has the function of supporting the workpiece and driving the workpiece to rotate.

10. Adjust the wheel dresser

The adjusting wheel dresser is installed on the adjusting wheel housing, and the adjusting wheel is trimmed with diamonds.

11. Adjust the wheel head

The adjusting wheel head is installed on the surface of the upper slide rail and can be rotated on the surface. Contains the adjustment wheel and the main shaft of the adjustment wheel.

12. Workpiece holder

The workpiece holder is installed on the lower sliding block to support the knife plate.

13. Knife board

The knife board is fixed on the workpiece holder to support the workpiece.

2. Features of Centerless Grinder

1. Continuous processing, no need to retract the tool, short copying time for clamping workpieces, and high productivity.

2. The support rigidity of the bracket and guide wheel positioning mechanism is better than that of ordinary cylindrical grinders and the center frame mechanism. The cutting amount can be larger, and it is conducive to the processing of slender shaft workpieces, and it is easy to realize high-speed grinding and powerful grinding.

3. The workpiece of the centerless cylindrical grinder is positioned on the positioning mechanism by the outer circle, and the grinding amount is the allowance on the diameter of the workpiece. Therefore, the wear of the grinding wheel, the compensation of the feed mechanism and the repeated positioning accuracy of the cutting mechanism have an impact on the diameter and size accuracy of the parts. Impact. Only half of the ordinary cylindrical grinder, no center hole is required, and it is easy to automate the loading and unloading in advance.

4. Wide grinding wheel centerless grinding machine through-type mechanism can be used to increase the machining allowance each time, and it can grind complex profiles in sequence or multi-wheel grinding during cut-in grinding, with high productivity and wide application range.

5. The centerless cylindrical grinder does not have a mechanism that guarantees the relative position accuracy (coaxiality, perpendicularity, etc.) of the ground surface and the non-ground surface, and the roundness is poor when grinding the circumferential intermittent outer surface.

6. The grinding surface is prone to odd roundness. If it is larger, it will often cause the illusion that the measured size is smaller than the maximum physical size, which will affect the assembly quality and work performance.

7. The adjustment of the machine tool is more complicated and time-consuming. Every time a workpiece with a different diameter is replaced, the height of the bracket, the distance and the related process parameters need to be adjusted. Therefore, it is difficult to adjust the technology and is not suitable for small batch and single-piece production.