With the continuous development of modern industry, steel structures have been widely used in the fields of construction, bridges, machinery manufacturing, etc. As one of the indispensable equipment in the steel structure manufacturing process, the application of metal band saws has received more and more attention.

Application scenarios

Steel structure manufacturing involves the processing of a large number of high-strength steel materials. Metal band saws have become key productivity tools in the following application scenarios:

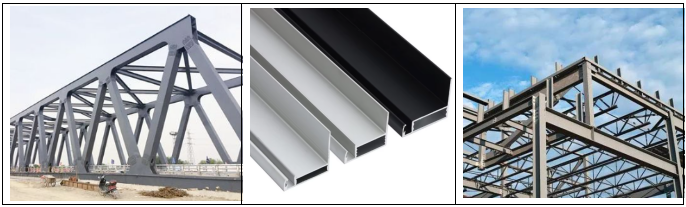

1.Cutting of large load-bearing components

H-shaped steel and I-beam cutting:For Q355B, S355JR and other construction steels, metal band saws can cut profiles up to 30 meters in length and 500 mm in thickness at one time, with an end surface roughness of Ra12.5μm, directly meeting the assembly requirements of high-strength bolt connections (HSFG).

Box beam forming:In the Shenzhen Ping An Financial Center project, the double-column band saw completed the cutting of box-shaped steel beams with a cross-section of 800mm*400mm, which is 4 times more efficient than traditional flame cutting and has no thermal deformation problems.

2. Complex node processing

Space grid nodes: Multi-angle bevel cutting is achieved through CNC programming. For example, in the steel structure node processing of the Beijing Daxing Airport terminal, the band saw machine shortened the traditional 72-hour processing cycle to 20 hours, and the accuracy error was controlled within ±0.3mm.

Special-shaped connecting plates: The band saw machine equipped with a laser positioning system can cut steel plates with a thickness of 10-100mm for making arc-shaped truss connectors, and the material utilization rate is increased to 98%.

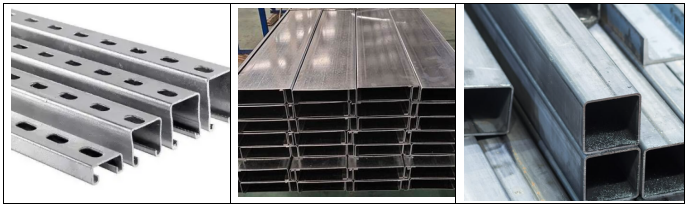

3. Modular building prefabricated parts production

Standard component batch processing: The fully automatic band saw cluster can continuously cut 120 C-shaped steels (160mm×60mm×20mm) per hour, with an accuracy error of ±0.2mm, supporting rapid assembly construction.

Ultra-thick steel plate processing: During the construction of the Shanghai Tower, the band saw successfully cut 150mm thick Q460GJD steel plates with a sawing seam of only 1.8mm, saving more than 2 million yuan in material costs.

Recently, we have a UAE customer who needs a fully automatic band saw to cut H-beams. The size of the customer’s workpiece is 600*700mm. According to the customer’s requirements, we matched the following GZ4265 parameter model for the customer

| Technical Specifications| Model | GZ4265(CH-650HA) | |

| Max.cutting size | Round | 700mm |

| Quadrate | 700×800mm | |

| Saw blade | Speed | 20~80 m/min (INVERTER) |

| Size | 54×1.6×8300 | |

| Guides | Carbide and bearing blade guides | |

| Cleaning | Wire brush & flood coolant | |

| Tension | Hydraulic | |

| Motor output | Blade | 11kw |

| Hydraulic | 2.2kw | |

| Coolant | 0.18kw | |

| Multiple feed | 500mm ×10 times | |

| Work Vise | Hydraulic(minimum clamping 275mm) | |

| Transmission | Gear Reducer | |

|

||

If you are also in the steel structure industry, need to cut large load-bearing components, process complex nodes or produce modular building prefabricated parts, and are looking for a suitable metal band saw, please contact Shanghai ANTISHICNC. We are a senior band saw equipment supplier with rich experience in machinery and equipment manufacturing and application, and can provide you with professional technical support.

Keywords: Metal band saw, Fully automatic metal band saw, Band saw