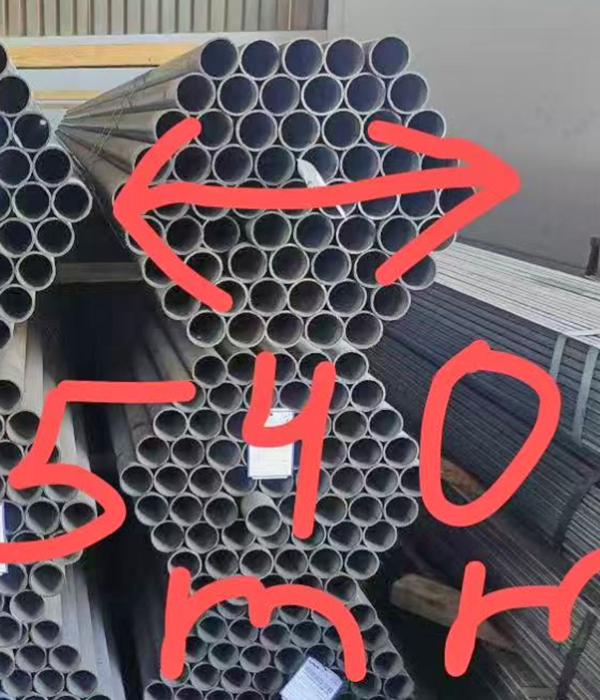

Recently, Shanghai ANTISHICNC received an inquiry from a customer in Uzbekistan regarding a metal band saw. The customer, a well-known local metal pipe manufacturing company, needed a metal band saw to complete their pipe production. Below are pictures of the customer’s actual product.

The customer required bundle cutting of the aforementioned materials, all made of Q235 carbon steel. The specific workpiece dimensions were: 60*2mm and 3mm*2mm for pipes, 48*2.5mm for tubes, 100*40*2.5mm for profiles, 63*63*6mm for angles, and other sizes of 28.32*2mm, 28*2mm, and 32*2mm.

|

|

Based on these requirements, we recommended our GHS4260 fully automatic straight-cut metal band saw. The following are the detailed specifications:

| Technical Specifications| Model | GHS4260 |

| Max. cutting size(mm) | 600*600 |

| Saw blade speed (m/min) | 27/45/69 |

| Saw blade specifications(mm) | 6640*41*1.3 |

| Feed rate | CVT |

| Main motor power | 5.5kw |

| Hydraulic motor power | 1.5kw |

| Water pump motor power | 0.09kw |

| Clamping method (Vice) | Hydraulic tensioning |

| Transfer method | Turbine shaft |

| Package Size | 3300*1700*2200mm |

| Weight | 2500kg |

In the process of communicating with customers, customers are interested in some optional accessories of our band saws. Let us learn more about the specific functions of these optional accessories.

| Accessory name | Specific functions | Detailed image |

| frequency converter | By changing the working power frequency of the motor, the cutting speed of the saw band can be controlled steplessly, thereby optimizing the cutting process, protecting equipment and saving energy. |  |

| Electric spiral chip removal | The main function of the electric chip conveyor is to automatically and continuously remove the metal chips generated during the cutting process from the cutting area and transport them to a designated collection container (such as a chip cart). |  |

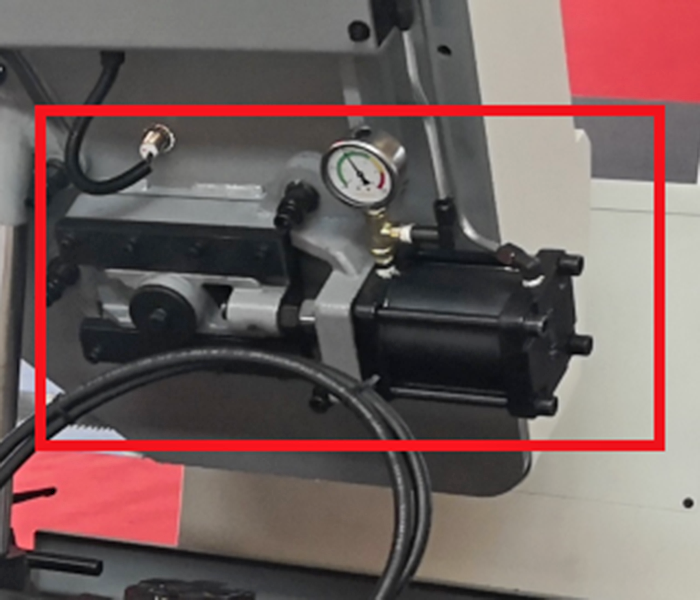

| Hydraulic tensioning | The primary function of a hydraulic tensioning system is to provide continuous, stable, and automatically adjustable tension to the saw blade, ensuring cutting accuracy, efficiency, and blade life.

Think of it like the string of a bow and arrow; it must be kept at just the right tension to work effectively and accurately. |

|

| Power failure protection | In the event of a sudden power outage, the system automatically executes a series of safety operations and fully saves the current processing status, ensuring safe resumption of production upon power restoration and minimizing losses.

In the event of a sudden power outage, the saw blade automatically retracts and detaches from the workpiece. The saw blade is effectively protected, resulting in minimal or no damage. The workpiece is also protected. Processing data is fully preserved, allowing for easy tracking of progress. Once power is restored, one-touch resumption of the interrupted cut ensures seamless continuity. |

|

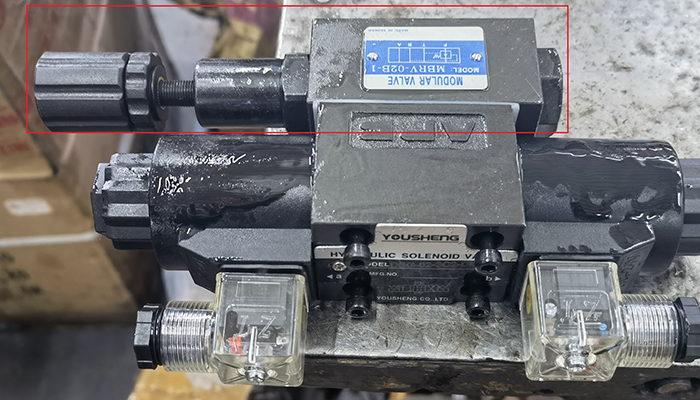

| Pressure reducing valve | Main Function: Reduces and stabilizes the high pressure from the oil pump in the hydraulic system to a desired, lower operating pressure, providing stable and controllable pressure for specific operating circuits.

Operating Principle: The blade tensioning of a hydraulic saw is typically performed by a hydraulic cylinder (tensioning cylinder). The high pressure generated by the oil pump is used to drive high-force components such as the main lift cylinder. However, if this high pressure is directly fed into the tensioning cylinder, the saw blade will be over-tensioned, easily breaking. |

|

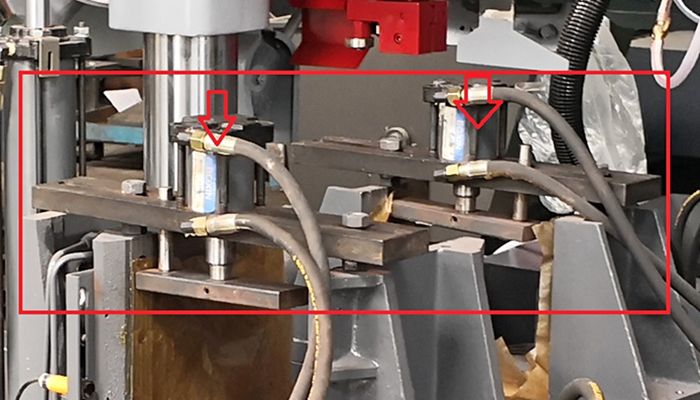

| Upper pressure device | A hold-down device (also known as a load clamp or upper clamp) acts as a “second pair of hands” in a metal band saw. Its primary function is to apply pressure from above the workpiece during the sawing process, firmly holding it against the worktable (or lower vise) and preventing it from moving, vibrating, bouncing, or rotating during cutting.

Effectively clamping irregular workpieces: For irregularly shaped castings, forgings, or profiles, a side vise may not have a flat clamping surface. A hold-down device, however, applies pressure directly on the top of the workpiece (which typically has a relatively flat top surface), providing secure clamping. Clamping short workpieces: For very short workpieces, the opening of a side vise may be too large to effectively clamp them. A hold-down device presses down on the workpiece, resolving this clamping challenge. Bundle cutting: When cutting multiple small-diameter bars simultaneously, a hold-down device can hold the entire bundle of materials together, preventing individual bars from rolling or bouncing, thereby enabling efficient batch cutting. |

|

If you also need a suitable metal fully automatic straight cut band saw machine, please consult Shanghai ANTISHICNC Machine. We are a senior supplier of metal machining equipment, with rich experience in manufacturing and using mechanical equipment, and can provide you with professional technical support.

Please send an email to: contact@antsmachine.com;

For more product information, please visit:https://www.antsmachine.com/

Keywords: Fully automatic metal band saw, Fully automatic metal straight cutting saw, Band saw