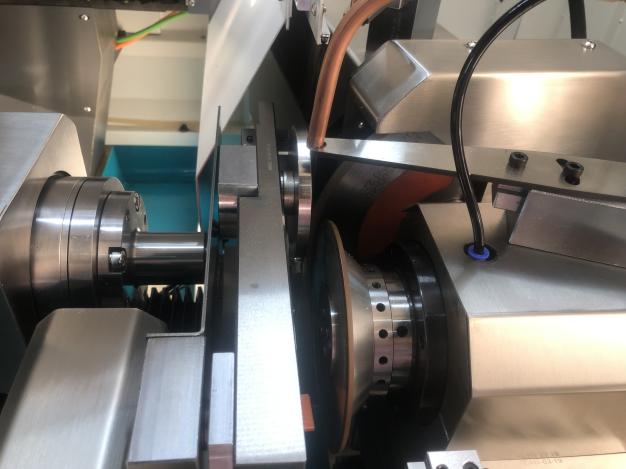

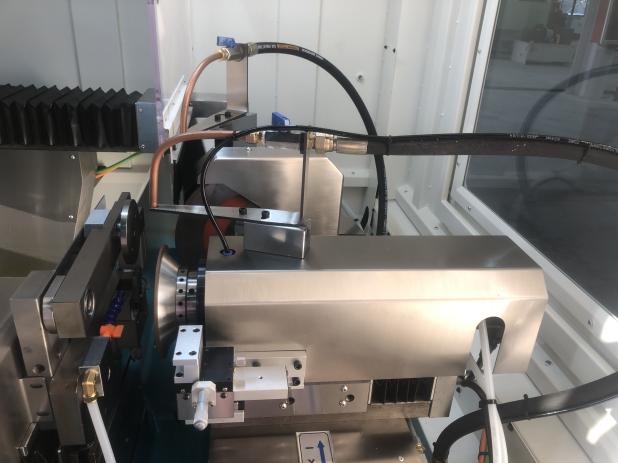

The H3 Series high-precision step grinder tool grinding machine is body and components made of high-grade cast iron FC-30, which has been artificially normalized heat treated and then subjected to natural aging treatment. Component processing uses world-class equipment such as YASDA, MITSUI SEIKI, TOSHIBA, and ELB for one-time clamping processing. The precision dimensions can reach the micron level, ensuring high-precision grinding machines for the basic components of the equipment. Its design concept is consistent with a 5-axis high-precision CNC cylindrical grinder from Switzerland, which can use plunge or multi-layer peeling grinding methods, and integrates a 3-axis robot automatic loading and unloading system. The machine tool grinding diameter range is 0.5-20mm. The H3 step grinder is an ideal machine for tool blank preparation and processing of punches, complex-shaped molds and workpieces with large aspect ratios.

The H3 series step grinder uses high-precision penetration or multi-layer peeling grinding methods to process various parts, such as tool blanks, boring tool blanks, threaded parts, flat parts and non-round punches, etc.

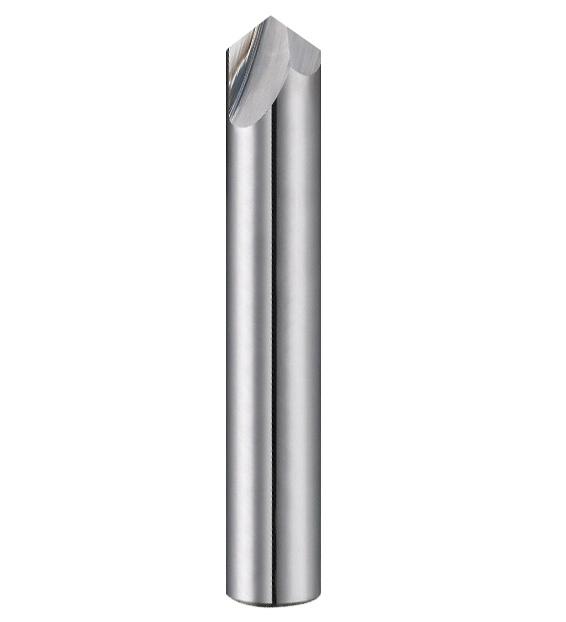

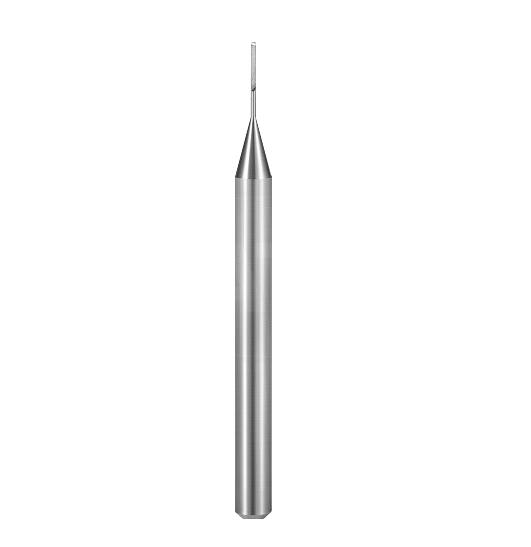

Recently, Shanghai ANTISHICNC received an inquiry from a Russian company that specializes in making various cutting tools. The customer mainly makes punches, cutting tools, boring tools, threaded parts, special-shaped punches, etc. The customer’s main workpiece diameter range is 1-20mm, and he wants to improve processing efficiency. After the customer contacted us, we learned that the customer’s factory has several 5-axis CNC tool grinders, and we want to introduce an H3 step difference grinder based on the original 5-axis CNC tool grinder to do various tool blank preparation processes. We tell our customers that the workpieces processed by one H3 step grinder can simultaneously meet the material requirements of four 5-axis CNC tool grinders for blank parts, which can greatly improve processing efficiency.

|

ANTISHI CNC H3 7-axis CNC step tool grinder (punch, boring tool, and other front-end processing processes) |

|

|

|

|

|

|

Customer Partially Processed Products |

|

|

|

|

|

The H3 high-precision step grinder, also known as a high-precision CNC cylindrical grinder, is very suitable for the front-line processing of various tool customers and can greatly improve production efficiency. The following are the technical parameters of H3 :

| Technical Descriptions | Unit | Model: H3 | |

| Clamping work piece diameter rang | mm | 0.5-20 | |

| Grinding work piece diameter range | mm | 0.05-20 | |

| Clamping / grinding work piece Maximum length | mm | 300/200 | |

| Control system (cnc-4 axis) | ANCA-X/Y/Z/Z′ | ||

| Feeding and receiving station system (cnc-3 axis) | ANCA-U/V/W | ||

| Rough grinding | Grinding wheel size (diameter) × width × Aperture) | mm | 250×20×31.75 |

| Grinding wheel speed | rpm | 0~9000 | |

| Maximum linear speed of grinding wheel | m/s | 90 | |

| Grinding wheel spindle motor | KW | 18.5/22/30 | |

| Fine grinding | Grinding wheel size (diameter) × width × Aperture) | mm | 150×20×31.75 |

| Grinding wheel speed (motorized spindle) | rpm | 0~12000 | |

| Grinding wheel maximum linear speed | m/s | 90 | |

| Grinding wheel spindle motor | KW | 3.5/8.5 | |

| X/Y/Z/Z′axis Minimum feed rate | mm | 0.001 | |

| X-axis stroke (rough grinding axle) | mm | 73 | |

| Y-axis stroke (fine grinding wheel axle) | mm | 40 | |

| Z-axis stroke (working head) | mm | 374 | |

| Z ‘axis stroke (fourth axis) | mm | 52 | |

| X/Y/Z/ Z′axis servo motor | KW | 2 | |

| Head spindle table motor | KW | 1 | |

| Working head Spindle speed | rpm | 0-3000 | |

| High pressure oil pump | KW | 0.25 | |

| Working head spindle rotation mode | fixed | ||

| Support length positioning mode | Front positioning | ||

| Manipulator U / V / W axis servo motor | KW | 1 | |

| Grinding fluid tank | mm | 300*300*1000 | |

| Gross weight (approx.) | Kg | 5000 | |

| Overall dimension (length) × wide × High) | mm | 2390*2752*2050 | |

If your company also has the same processing needs, please feel free to contact us. You can provide processing drawings, and our very professional engineers will comprehensively evaluate the drawings and recommend you a suitable machine based on the processing material, workpiece size, and processing requirements. Whether you need an H3 step grinder for the front process or a 5-axis CNC tool grinder for the back process, we can meet your needs.