The follow-up grinder is a common metal processing equipment, widely used in the manufacturing industry. Through perfect flexible design and user-friendly graphical programming design, the follow-up grinder can be widely used in various industries such as aviation, medical, hydraulic, mold, high-end automobile manufacturing, robot reducer core parts, special-shaped components, etc. The follow-up grinder is suitable for grinding various eccentric shafts, crankshafts, and special-shaped long shafts. Our company’s GP32 follow-up grinder has a maximum grinding diameter of 320mm and a distance between the two centers of 650mm. The maximum load is 20-90KG.

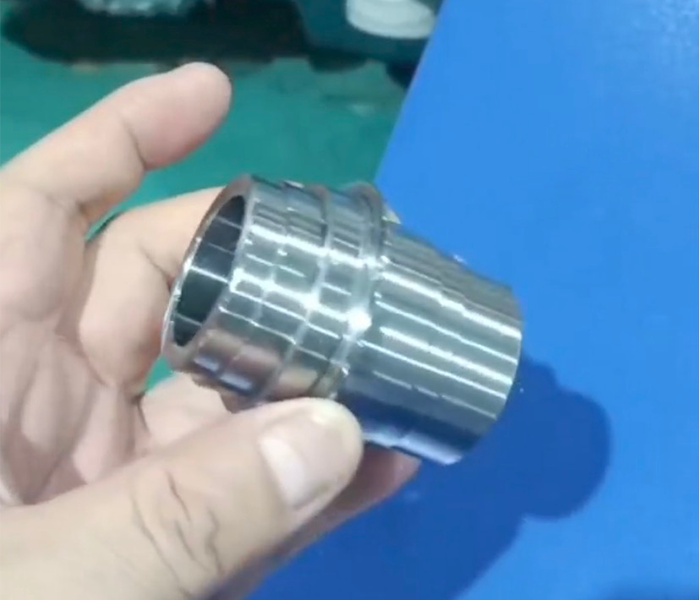

Recently, the Shanghai ANTISHICNC team received a request from a major precision parts processing company. The customer needs to process precision parts of harmonic reducer, multi-step eccentric circle. According to the customer’s requirements, we recommended the GP32 follow-up grinder. After processing the workpiece drawings according to the customer’s drawings, the customer was very satisfied with the sample.

|

|

|

| Customer on-site sampling of harmonic reducer precision components | ||

Features of ANTISHICNC follow-up grinder GP32:

Stable and reliable – super rigid structure and excellent precision performance

Outstanding performance–excellent performance for processing Special-shaped parts

High precision, high rigidity and high efficiency are the basic characteristics of this grinder

Easy to operate–Simple and easy-to-use operating system:

Completely graphical programming

Easy to learn and use

Quick setup, saving operation time

Modular grinding and dressing cycles

Versatile functions, suitable for ISO programming

CAD/CAM software extensions

If you are also a manufacturer of related precision parts and have various processing needs for eccentric shafts, crankshafts, and special-shaped long shafts, you are welcome to consult Shanghai ANTISHICNC. We have rich experience in producing high-precision grinders and can provide you with professional technical support. Company email: contact@antsmachine.com.