The drilling machine in which the head stock moves horizontally on the rocker arm is called the rocker arm drilling machine. The rocker arm drilling machine is a kind of drilling machine in which the rocker arm can rotate and lift around the column. Usually, the head stock moves horizontally on the rocker arm. When machining holes on a vertical drilling machine, the centering of the tool and the work piece is achieved by the movement of the work piece, which is obviously very inconvenient for some large and heavy work pieces; and the radial drilling machine can be used to move the position of the tool axis. Come to center, which brings great convenience to machining holes on large and heavy work pieces in single-piece and small-batch production.

It can also be called a radial drill. It is a kind of hole processing equipment, which can be used for various forms of processing such as drilling, reaming, reaming, tapping and scraping end faces. According to the clamping structure of machine tools, radial drills can be divided into hydraulic radial drills and mechanical radial drills. Among all kinds of drilling machines, radial drilling machines are easy to operate, flexible, have a wide range of applications, and are typical, especially suitable for single-piece or mass production of holes with large porous parts, and are common machine tools in general machining workshops.

Radial drill press, also known as cross drill. The spindle box can move left and right on the rocker arm and rotate around the column with the rocker arm. The rocker arm can also be lifted up and down along the outer column to adapt to the processing of work pieces of different heights. Smaller work pieces can be mounted on the table, and larger work pieces can be placed directly on the machine base or on the ground.

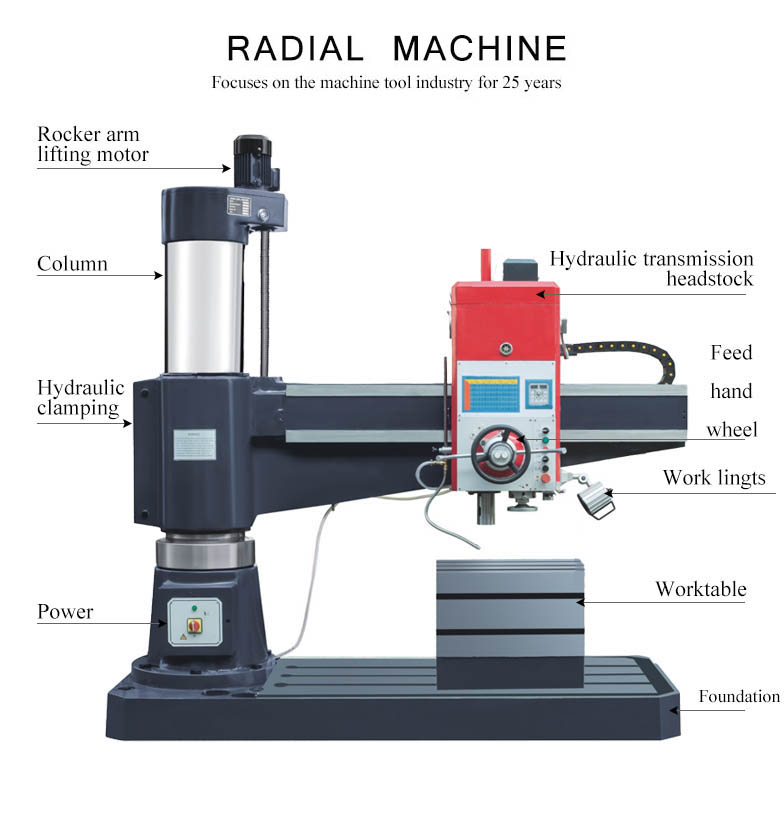

Radial drilling machines are widely used in single-piece and small and medium batch production to process holes in work pieces with large volume and weight. The radial drilling machine has a wide processing range and can be used to drill various screw holes, threaded bottom holes and oil holes of large work pieces. The radial drilling machine is used to process small and medium-sized holes on heavy work pieces or porous work pieces. It is mainly composed of a base, a column, a rocker arm, a spindle box, and a spindle work piece table. When the rocker arm drilling machine is working, the rocker arm can rotate around the column, and the spindle box can move radially on the rocker arm. This allows the drill to be aligned with the axis of each hole being machined for hole machining. Use more flexible. Generally, when drilling a work piece, the work piece is often clamped on the worktable. When machining large work pieces, the work piece can be clamped on the base of the drilling machine. Depending on the height of the work piece, after the locking device is released, the rocker arm can move up and down along the column, so that the spindle box and the drill head are at the proper height.

Radial drilling machines are generally configured in production occasions such as single-piece mechanical products, small batch production workshops, product assembly workshops, and mechanical repair workshops.

The main variants of the radial drilling machine are the slide type and the universal type. The sliding seat type radial drilling machine is made by changing the base of the basic radial drilling machine into a sliding seat. The sliding seat can move along the guide rail of the bed to expand the processing range. It is suitable for boilers, bridges, rolling stock and shipbuilding, mechanical processing, and other industries. The rocker arm of the universal radial drilling machine can move horizontally in addition to vertical and rotary movements. The spindle box can be tilted on the rocker arm to adapt to the processing of various parts of the work piece. In addition, there are cart-type, wall-type and digitally controlled radial drilling machines.

The main structure

The radial drilling machine is mainly composed of a base, an inner column, an outer column, a rocker arm, a spindle box and a worktable.

The inner column is fixed at one end of the base, and the outer column is covered with an outer column, and the outer column can rotate 360 degrees around the inner column. One end of the rocker arm is a sleeve, which is fitted on the outer column to move up and down. Since the screw rod is integrated with the outer column, and the lifting nut is fixed on the rocker arm, the rocker arm cannot rotate around the outer column, but can only rotate around the inner column together with the outer column.

The head stock is a composite part, which consists of the main drive motor, the main shaft and the main shaft transmission mechanism, the feed and speed change mechanism, and the operating mechanism of the machine tool. The head stock is installed on the horizontal guide rail of the rocker arm, and can be operated by the hand wheel to make it move along the rocker arm on the horizontal guide rail.

Mode of motion

When processing, the head stock is fastened on the rocker guide rail by a special tightening device, the outer column is fastened to the inner column, the rocker arm is fastened to the outer column, and then the drilling process is performed. During drilling, the drill bit performs longitudinal feed while rotating and cutting, and its motion form is:

(1) The main motion of the radial drilling machine is the rotational motion of the main shaft

(2) The feed movement is the longitudinal feed of the spindle

(3) The auxiliary movements include: the vertical movement of the rocker arm along the outer column, the movement of the head stock along the length of the rocker arm, and the rotary movement of the rocker arm and the outer column together around the inner column.

Main features of hydraulic radial drilling machine

1. Adopt hydraulic pre-selection speed change mechanism, which can save auxiliary time;

2. Spindle forward and reverse rotation, parking (braking), speed change, neutral and other actions are controlled by a handle, which is easy to operate;

3. The spindle box, rocker arm, inner and outer columns adopt hydraulically driven diamond block clamping mechanism, and the clamping is reliable;

4. The upper guide rail of the rocker arm, the spindle sleeve and the inner and outer column rotating raceways are all quenched, which can prolong the service life;

5. In addition to manual movement of the spindle box, it can also be motorized;

6. There are perfect safety protection devices, outer column protection and automatic lubrication devices;

Main features of mechanical radial drilling machine

1. Two-speed motor;

2. Single handle speed change;

3. Interlock clamping;

4. Mechanical and electrical double insurance;

5. Open the door and power off, emergency stop button.

As a leading manufacturer of industrial lathe machinery and machine tools in China, Shanghai ANTS has 25 years of experience in the production of radial drills, the products are sold to Hebei, Shaanxi, Hunan, Henan, Jiangsu, Shandong, Guangdong, Shanghai and other places. More than 300 professional after-sales service personnel in 83 offices across the country provide customers with pr-sales and after-sales services at any time. The products are deeply trusted by customers and are exported to more than 20 countries and regions such as the United States, Germany, Italy, India, Thailand, and Russia. Especially in recent years, they have been widely used in major domestic well-known enterprises such as China National Heavy Duty Truck, Ministry of Aeronautics and Space, Zhongyuan Special Steel, Zhengmei Machinery, Shanghai Heavy Industry, Wuhan Iron and Steel, Anshan Iron and Steel and Sany Heavy Industry have the characteristics of rich experience, excellent.