The CNC system of a CNC lathe serves as its control core. It is responsible for reading machining programs (such as G-codes) and precisely controlling various components of the machine, including axis movement, spindle speed, and tool operations. Through motor drives and control software, the system enables automated, high-precision machining of parts. Common CNC system brands include FANUC, Siemens, Mitsubishi, GSK, among others. This article will introduce the features of the three high-end advanced CNC systems used by ANTSHICNC.

1.GSK 988TA Bus-Type CNC System for Lathes

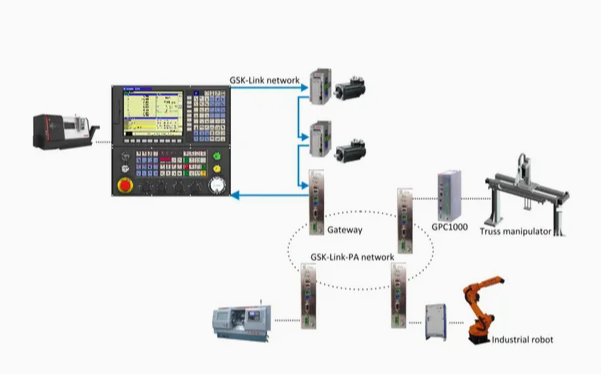

The GSK 988TA CNC system for turning centers utilizes GSK Link industrial Ethernet bus technology and is compatible with the GR-L series servo devices. It supports online servo tuning and can connect to linear scales, magnetostrictive/magnetic grating encoders, and rotary encoders to achieve full closed-loop control of feed axes and high-precision CS-axis control. This system meets the requirements of mid-to-high-end turning centers for high precision and high-efficiency machining.

Technical Features

Supports Remote Monitoring and Fault Diagnosis

Based on an Ethernet LAN interface, the system enables remote monitoring of CNC machines, fault diagnosis, and the collection and analysis of reliability data. This includes the upload and download of machining files, parameter files, tool offset files, and more—truly realizing remote monitoring functionality. FTP communication protocol is supported.

High-Speed, High-Precision Control

Utilizing the GSK Link industrial Ethernet bus, the system supports a maximum running speed of 100 m/min and nanometer-level interpolation.

Equipped with GR-L series servo systems and high-resolution absolute encoders as standard, it achieves full closed-loop control of feed axes and high-precision CS-axis control.

Supports Turn-Mill Compound Machining

The system can be configured with up to 8 feed axes and 4 spindles, all of which can function as CS axes. This allows for complete machining operations—turning, milling, drilling, tapping—in a single setup. It offers a simple, practical, and cost-effective solution for compound machining. The system also supports polar coordinate interpolation, cylindrical interpolation, rigid tapping, and drilling/boring cycles.

2.SINUMERIK 808D CNC System for Lathes

The SINUMERIK 808D offers state-of-the-art CNC technology for entry-level lathes and milling machines. With coated circuit boards and strict adherence to German quality standards during production, Siemens ensures the reliability and durability of this cost-effective CNC system. Backed by over 50 years of expertise in CNC technology and as a member of the SINUMERIK family, the 808D allows operators to benefit from consistent CNC operation and programming across the entire product line.

Technical Features

Keyboard design optimized for different machining processes

Mechanically sealed keys covered with protective film

Front panel equipped with a USB interface (IP65 rated), supporting USB flash drives and USB computer keyboards

Serial interface RS232C

Machine control panel with rotary switches for adjusting feed and spindle override rates

Long-lasting, durable battery

Front panel protection rating of IP65

Panel-based CNC system design

Fanless operation

No hard disk

7.5″ color LCD display with 640×480 resolution

Real-time LED display of tool numbers

Maximum precision—accuracy down to the nanometer level

PC-style file handling for simpler and faster file management

Intelligent JOG functions—measurement and machining cycles fully visualized with graphics

Advanced SINUMERIK CNC language offering a wide range of machining cycles

3.FANUC Oi-F Plus CNC System for Lathes

The FANUC Oi-F Plus is a high-reliability, high-cost-performance nano CNC system developed by FANUC based on its 30i-B series, in response to market demands. Building upon the original Oi-F series, it incorporates more standard functional configurations, further enhancing both performance and value for money.

Technical Features

A Brand-New Operating Experience

Fully upgraded design

Equipped with iHMI (Type 0)

Seamless operation interface consistent with the 30i series

Supports up to a 21.5″ PANEL iH Pro display

Personalized functions included as standard

Supports a wide range of industrial networks

Enhanced Performance

Integrated with FANUC’s latest CNC and servo technologies

Expanded memory capacity

Intelligent servo control

Surface fine-finishing technology

High-efficiency machining technology

Comprehensive field network compatibility

Greater Operational Efficiency

Insulation degradation detection function

Extensive predictive fault detection capabilities

Diagnostic and maintenance functions to easily locate faults and reduce recovery time

Intelligent Servo Control

Intelligent servo control refers to a group of servo functions that automatically perform real-time optimization in response to changes in machine tool conditions such as load and temperature.

Surface Fine-Finishing Technology

This refers to CNC and servo technologies used to achieve high-quality machining. It enables interpolation of high-precision programs output from CAD/CAM, high-speed execution of small segment programs, smooth toolpath generation, and accurate command tracking.

High-Efficiency Machining Technology

By optimizing acceleration and deceleration based on motion conditions and maximizing spindle capabilities, this technology reduces external signal processing time and shortens the overall machining cycle time.

Conclusion:

The CNC system is the control core of a CNC lathe, determining the machine’s machining accuracy and efficiency. Leading CNC system brands on the market today include FANUC, Siemens, Mitsubishi, and GSK. This article has focused on the features of three high-end CNC systems used by ANTSHICNC:

GSK 988TA features bus-based connectivity, high-speed and high-precision control, turn-mill compound machining capability, and remote monitoring functions.

SINUMERIK 808D by Siemens offers stable hardware, an intuitive graphical user interface, and powerful machining cycles—ideal for entry-level lathes.

FANUC Oi-F Plus stands out in terms of performance, user experience, and intelligent machining. It integrates intelligent servo control and surface fine-finishing technology, greatly improving operational efficiency and machining quality.

Together, these three systems showcase the technical strengths of Chinese high cost-performance, German stability and user-friendliness, and Japanese precision and efficiency.