Overview

Vertical turret milling machine is also called radial milling machine, universal milling machine, which is a kind of turret milling machine, which belongs to the category of milling machines. The difference between a vertical turret milling machine and a turret milling machine is that its main shaft can only feed vertically, and the traveling direction of the main shaft forms an angle of 90° with the plane of the worktable, so it is called a vertical turret milling machine.

The vertical turret milling machine can be widely used for processing planes, bevels at any angle, milling keyways, grooves, and can also be rotated, reamed, and boring. The milling head can rotate 90 degrees left and right, and 45 degrees front and rear. The ram can be used. Pan 360 degrees. The main shaft has a wide speed range and a high speed. The main shaft sleeve can be motorized and fixed-range feed, and is equipped with an overload protection device. Spindle sleeves, machine tool guides, and worktables are all hardened with high frequency, which is beautiful and practical. The vertical turret milling machine can be optionally equipped with a motorized feed device and a digital display system.

Main feature

◎Front and rear slides and high-frequency hardening treatment, precision grinding.

◎The surface of the spindle tube is hardened by high-frequency hardening treatment and precision ground.

◎The slideway of the lift seat is hardened and precisely ground.

◎The Y and Z axes are square slides.

◎The X axis is a dovetail slide.

◎The bed is integrally cast, with strong rigidity and long life.

Technical Parameters

Workbench size: 1370 x 360mm

Left and right stroke: 900mm

Front and back stroke: 300mm

Up and down stroke: 380mm

Spindle motor: 4HP

Spindle taper: NST40

Spindle diameter: 105mm

Spindle speed: (vertical) 80-5440rpm (16 speed)

Tilt angle of end milling head: 90°left-90°right

T-slot: 16mm x 3 x 65mm

Extension arm stroke: 600mm

Machine weight: 1700kg

Maintenance of milling machine

1. Cleaning: disassemble and clean each part of the oil scraper; wipe each sliding surface and guide rail surface, wipe the workbench and the horizontal, lift screw, wipe the knife feeder and the knife holder.

2. Lubrication: Keep all oil holes clean and unobstructed and add 32# lubricant; add lubricant to each guideway surface, sliding surface and each screw rod; check the oil pot, oil surface, and add oil to the elevation position.

3. Tighten: check and tighten the pressure plate and the inserting screw; check and tighten the workbench limit screw, the drive mechanism of the knife, the three-ball handle, and the workbench bracket screw.

4. Adjustment: Check and adjust the tightness of the milling head belt, pressing plate and inserts; check and adjust the limit stop and screw gap.

5. Anti-corrosion: remove the rust of all parts, protect the painted surface, and avoid collision; the guide rail surface of the standby equipment, the sliding screw hand wheel and other exposed parts that are easy to rust are coated with oil for anti-corrosion.

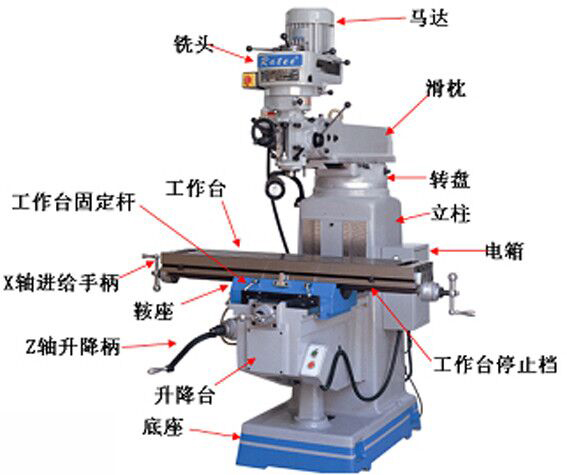

Milling machine structure

Milling machine base,

Milling machine bed,

Workbench,

Milling machine column,

Milling head.